Wood Pellet Making Machine Price

The wood pellet making machine price typically ranges from USD 20,000 to USD 3,000,000, depending on machine capacity, configuration, and automation level. The machines convert biomass materials such as sawdust, wood chips, rice husk, straw, and bamboo into high-density fuel pellets for heating, industrial boilers, and biomass power generation.

What Is The Wood Pellet Making Machine?

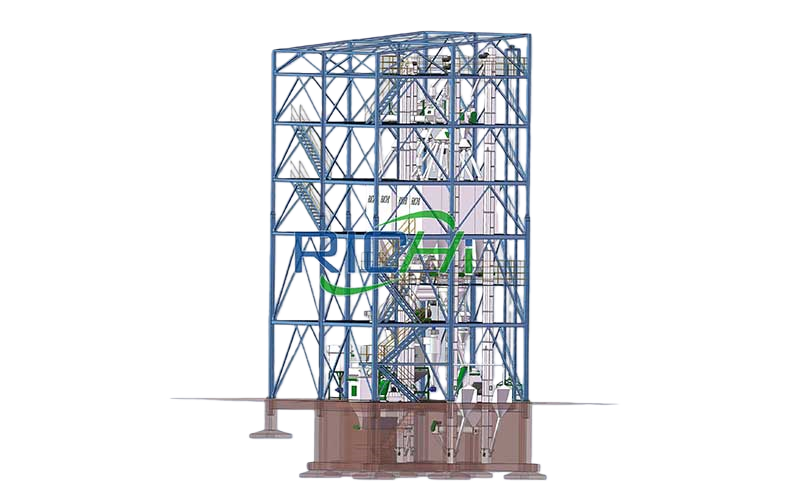

A wood pellet making machine is a complete set of equipment used to process biomass raw materials into uniform, high-density wood pellets. Rather than a single standalone device, it is a turnkey production system that includes multiple stages of preparation, processing, and post-production handling. The purpose of the machine is to transform waste biomass—such as sawdust, wood chips, rice husk, straw, bamboo, and other agricultural or forestry residues—into clean, renewable fuel pellets with stable quality and high calorific value.

The typical biomass pellet making machine for wood consists of several key components: raw material feeding and crushing equipment, drying systems, pellet mills, cooling units, screening and packaging machines, and sometimes storage and conveying systems. Each component plays a crucial role in ensuring continuous production, consistent pellet quality, and efficient operation.

Depending on production capacity, automation level, configuration, and auxiliary equipment, the wood pellet making machine price generally ranges from USD 20,000 to USD 3,000,000. The final investment varies according to project requirements, raw material characteristics, and the level of customization needed to ensure efficient and stable long-term operation.

Different Price Of RICHI Complete Wood Pellet Making Machine For Sale

RICHI Machinery wood pellet maker machines offer a variety of configurations to meet diverse production capacity requirements and investment budgets. Whether you need a small machine with a capacity of 0.2 tons/hour or a large industrial-grade pellet plant with a capacity of 40 tons/hour, RICHI offers a customized, cost-effective solution. Wood pellet making machine prices range from $15,000 to $3,000,000, depending on production capacity, degree of automation, and equipment configuration.

0.2-0.3T/H Small Wood Pellet Making Machine

Wood Pellet Making Machine Price: 15,000-150,000 USD

0.3-0.5T/H Wood Pellet Making Line

Wood Pellet Making Line Price: 25,000-180,000 USD

1.5-2.0T/H Wood Pellet Making Plant

Wood Pellet Making Plant Price: 50,000-300,000 USD

3.0-4.0T/H Wood Pellet Making Machine

Wood Pellet Making Machine Price: 90,000-450,000 USD

5.0-6.0T/H Wood Pellet Maker Machine For Sale

Wood Pellet Maker Machine Price: 120,000-600,000 USD

6.0-8.0T/H Wood Pellet Pelletizing Line

Wood Pellet Pelletizing Line Price: 150,000-700,000 USD

10-12T/H Wood Pellet Manufacturing Machine

Wood Pellet Manufacturing Machine Price: 250,000-1,100,000 USD

12-15T/H Wood Pellet Processing Machine

Wood Pellet Processing Machine Cost: 450,000-1,450,000 USD

20-24T/H Wood Pellet Making Machine

Wood Pellet Making Machine Price: 550,000-2,100,000 USD

20-40T/H Wood Pellet Manufacturing Plant

Wood Pellet Manufacturing Plant Price: 550,000-3,000,000 USD

What Affects The Wood Pellet Making Machine Price?

The wood pellet making machine price is not fixed and varies according to actual production needs and system configuration. Understanding the key factors that influence pricing helps investors evaluate equipment options more clearly and make cost-effective decisions when planning a pellet production line.

1

Production Capacity

Required output directly affects machine size, power consumption, and auxiliary equipment selection, making capacity one of the most important price-determining factors.

2

Raw Material Characteristics

Moisture content, hardness, and particle size of raw materials influence the choice of crushers, dryers, and pellet mills, which in turn impacts the overall equipment cost.

3

Automation Level

Higher automation reduces labor dependence and improves production stability, but usually results in a higher initial investment.

4

Equipment Configuration & Customization

Customized layouts, optional equipment, and future expansion considerations can increase upfront costs while providing better long-term operational efficiency.

Different Pellet Making Machine Price In Production Line

The wood pellet making machine price in a production line is not determined by a single piece of equipment, but by the overall system configuration and production requirements. Factors such as raw material characteristics, target capacity, automation level, and the inclusion of auxiliary systems like drying, cooling, and packaging all have a direct impact on the final investment cost.

Dryer Machine

Dryer Price: 15,000-50,000 USD

Vibrating Screen

Vibrating Screen Price: 2,000-10,000 USD

Packaging System

Bagging Machine Price: 5,000-20,000 USD

How Wood Pellets Are Produced in a Standard Production Line?

Producing high-quality wood pellets follows a standard process including raw material preparation, crushing, drying, pelletizing, cooling, screening, and packaging, ensuring uniform pellets with stable density and calorific value.

The wood pellet making machine price depends on raw material characteristics, production capacity, automation level, and equipment configuration, all of which directly influence total investment and operating efficiency.

By understanding this workflow, pellet producers can select suitable equipment based on their production needs and budget, ensuring efficient operation and consistent pellet quality.

Raw Material Preparation

01

Biomass materials like sawdust, wood chips, or straw are collected and sorted. Large impurities are removed to protect the equipment and ensure pellet quality.

Crushing

02

Hammer mills or crushers grind the raw materials into uniform particles, improving pellet density and production efficiency.

Drying

03

A rotary dryer reduces excess moisture to 12–18%, ensuring strong and durable pellets and smooth pelletizing.

Pelletizing

04

The pellet mill presses dried materials through a die, forming cylindrical pellets with high density and consistent quality.

Cooling

05

Counterflow coolers lower pellet temperature to room temperature, preventing deformation and breakage.

Screening

06

Vibrating screens remove fines and broken pellets, ensuring a uniform, high-quality final product.

Packaging

07

Finished pellets are packed into bags or bulk containers for storage and transport, keeping them dry and intact.

How To Choose The Best Wood Pellet Making Machine For Efficient Production?

Choosing the best wood pellet making machine is essential for achieving efficient, stable, and cost-effective pellet production. A suitable solution should match the characteristics of raw materials, required production capacity, and automation expectations while maintaining reliable long-term performance. By evaluating these key factors as a complete system, producers can improve operational efficiency, reduce unnecessary costs, and ensure that the selected equipment delivers value aligned with the overall investment plan.

Match Raw Materials with Required Capacity

Different wood materials have varying structures and moisture levels. Choosing equipment that fits both raw material type and target output helps maintain stable pellet quality and smooth operation.

Focus on Automation and System Compatibility

A properly integrated production line improves efficiency and reduces manual intervention. Coordinated control between key processes supports consistent output and reliable operation.

Consider Long-Term Cost and Future Expansion

Energy use, maintenance needs, and scalability should be evaluated alongside initial investment to ensure sustainable production and long-term returns.

Different Global Cases With Different Wood Pellet Making Machine Price

The wood pellet making machine price varies across different countries and projects due to factors such as production capacity, raw materials, and equipment configuration. Exploring global cases can help potential buyers understand how production needs and local conditions influence investment. With over 30 years of industry experience, RICHI Machinery has successfully delivered pellet machines and related pellet equipment products to more than 140 countries and regions, providing tailored solutions for diverse biomass pellet production projects worldwide.

Wood pellet Making Machine For Sale Indonesia

- Production Capacity: 1-2T/H

- Project Country: Indonesia

- Estimated Price: USD

- Raw Material: Sawdust, wood chips, and palm-related biomass residues sourced locally.

- Project Background: The client aimed to utilize agricultural and forestry waste for local fuel pellet production, selecting a compact line with a reasonable wood pellet making machine price under limited budget conditions.

- Client Feedback: The system runs smoothly and adapts well to mixed biomass materials, delivering stable pellet quality and cost-effective performance.

Wood Production Line For Sale Canada

- Production Capacity: 2-3T/H

- Project Country: Canada

- Estimated Price: USD

- Raw Material: Sawdust and wood shavings from nearby sawmills, with uniform moisture content.

- Project Background: The client planned a medium-small full automatic biomass wood pellet line in Canada for regional heating markets, focusing on automation while keeping overall equipment investment controllable.

- Client Feedback: The equipment delivers consistent output, reduces labor input, and meets local pellet quality standards.

Wood Pellet Production Line In Poland

- Production Capacity: 4T/H

- Project Country: Poland

- Estimated Price: USD

- Raw Material: Hardwood sawdust, wood chips, and furniture factory residues.

- Project Background: The client targeted domestic and export markets, selecting a mid-capacity solution after evaluating different configurations and their impact on the wood pellet making line price.

- Client Feedback: The line shows strong adaptability and efficient pelletizing performance across various raw materials.

Wood pellet Making Plant In Austria

- Production Capacity: 5T/H

- Project Country: Austria

- Estimated Price: USD

- Raw Material: Softwood sawdust and forestry residues

- Project Background: The wood biomass pellet making plant focused on industrial and residential heating, with attention to equipment durability and long-term investment value rather than initial cost alone.

- Client Feedback: The customer was satisfied with pellet density, appearance, and the stable long-term operation of the system..

Wood pellet Making Machine In United States

- Production Capacity: 10T/H

- Project Country: United States

- Estimated Price: USD

- Raw Material: Pine sawdust, wood chips, and forestry processing residues.

- Project Background: The client developed a commercial-scale pellet plant for energy and bulk heating markets, emphasizing automation and scalability aligned with the selected equipment investment.

- Client Feedback: The system operates continuously with stable output, supporting long-term commercial production goals.

Wood pellet Machine For Sale South Africa

- Production Capacity: 20T/H

- Project Country: South Africa

- Estimated Price: USD

- Raw Material: Forestry waste, wood chips, and mixed biomass materials.

- Project Background: The client invested in a large-scale biomass energy project, focusing on system integration efficiency and long-term economic value rather than short-term cost.

- Client Feedback: The production line performs reliably under high-load conditions and delivers solid economic returns over time.

Video Showcase Of Wood Pellet Making Machine

Seeing the equipment in real operation is one of the most effective ways to understand its performance and production capability. Through these wood pellet making machine videos, you can clearly observe the pelletizing process, line configuration, and on-site working conditions, helping you better evaluate equipment suitability, production efficiency, and overall investment value before making a decision.

Key Technical Characteristics Of Wood Pellet Maker

When evaluating a wood pellet making machine, buyers are not only concerned about output capacity, but also long-term stability, energy efficiency, adaptability to raw materials, and overall investment value. These technical characteristics directly affect pellet quality, operating costs, and the final wood pellet making machine price. Understanding the core features helps customers select equipment that delivers reliable performance and sustainable returns.

Why Choose Our Wood Pellet Making Machine?

Choosing the right equipment supplier is just as important as selecting the machine itself. Our wood pellet making machine solutions are designed as complete, well-matched systems that focus on production stability, energy efficiency, and long-term operational reliability. By combining proven engineering with flexible configuration options, we help pellet producers achieve consistent output and investment value that aligns with real production needs rather than short-term pricing alone.

High-Quality Equipment

Our wood pellet making machines are manufactured in accordance with strict international standards and have passed multiple global certifications.

Key components are produced using high-quality materials and advanced processing technology to ensure stable performance, long service life, and consistent pellet quality under long-term operation.

Customized Solutions

Every pellet project has different raw materials, capacity requirements, and investment expectations.

We provide customized equipment configurations and complete production line solutions based on the client’s specific needs, ensuring optimal system matching, efficient operation, and a balanced overall investment.

Extensive Experience

With projects in over 140 countries and regions worldwide, RICHI has extensive experience in wood pellet production.

RICHI Machinery turnkey service ensures professional guidance and reliable support for clients of all scales, from project planning and equipment installation to commissioning and operation.

FAQ

Before investing in a wood pellet making machine or a complete production line, many customers have questions about pricing, configuration, capacity selection, and long-term operation. The following frequently asked questions address the most common concerns to help you better understand the equipment, production process, and overall investment considerations.

I plan to use sawdust mixed with wood chips, but the moisture content is relatively high. Can this material be pelletized directly?

+

Sawdust mixed with wood chips is a commonly used and suitable raw material for wood pellet production. However, when the moisture content is relatively high, direct pelletizing is usually not ideal. For most wood pellet production systems, the recommended moisture range before pelletizing is typically around 12–18%, depending on the material structure and equipment configuration.

When the moisture content is excessive, direct pelletizing may result in unstable pellet formation, reduced pellet density, higher energy consumption, and increased wear on key components such as the ring die and rollers. Excess moisture can also negatively affect pellet strength, leading to cracking during cooling, storage, and transportation.

Therefore, it is usually recommended to add a drying process before pelletizing and use a dryer to properly control the moisture content of the raw materials. Proper drying helps ensure stable operation, improves pellet quality, and supports long-term, reliable performance of the pellet production.

I already have a crusher. Can I buy only the pelletizing part to reduce the total price?

+

Yes, in many cases this is possible. If your existing crusher can produce raw materials with suitable particle size and stable performance, the production line can be customized to include only the pelletizing system and necessary auxiliary equipment. This approach helps reduce the total investment while maintaining efficient pellet production.

However, it is important to evaluate whether the crusher output matches the requirements of the pellet mill in terms of particle size uniformity, capacity, and material consistency. If the crusher does not fully meet these requirements, additional adjustments or auxiliary equipment may be needed to ensure stable operation and consistent pellet quality.

With proper technical assessment and system matching, purchasing only the pelletizing section can be a cost-effective solution for investors looking to control the overall project budget.

I’m a first-time investor and plan to start with 1–2T/H capacity. What is the approximate price range?

+

For first-time investors planning a wood pellet production line with a capacity of 1–2 T/H, the approximate wood pellet making machine price range for a customized and well-matched solution is typically around USD 20,000 to 140,000. The final investment depends on factors such as the level of automation, the inclusion of auxiliary systems (like dryers, coolers, and packing machines), and the specific raw material conditions.

A basic setup with essential equipment will usually be closer to the lower end of this range, while a more automated and complete production line with advanced features may approach the higher end. Discussing your raw material type and production goals with a supplier will help you get a tailored estimate that reflects both performance expectations and long-term operational efficiency.

Can I upgrade from 2T/H to 4T/H later without replacing all the equipment?

+

Yes, in most cases this is achievable—especially when the wood pellet making machine is designed with scalability in mind from the beginning. RICHI wood pellet production lines adopt a modular design concept, allowing key systems such as material conveying, electrical control, and plant layout to be retained during future capacity expansion.

When upgrading from 2T/H to 4T/H, some core equipment—mainly the pellet mill and, in certain cases, the drying system—may need to be upgraded or supplemented. However, with proper initial planning, many auxiliary systems can continue to operate without replacement, significantly reducing additional investment and downtime.

By discussing long-term production plans at the early project stage, RICHI engineers can help configure an expandable solution that supports smooth capacity upgrades while protecting your initial investment and ensuring stable, efficient operation.

Does a higher price always mean better pellet quality? What are the main operating costs after purchasing the equipment?

+

A higher wood pellet making machine price does not always guarantee better pellet quality. Pellet quality depends more on proper equipment matching, die and roller design, raw material condition, and process control rather than price alone. A well-configured production line that matches the raw material characteristics often delivers more stable pellet quality than an over-configured or mismatched system.

After purchasing the equipment, the main operating costs typically include electricity consumption, labor, routine maintenance, wear parts such as ring dies and rollers, and raw material pre-processing. When evaluating the overall investment, it is important to consider not only the initial wood pellet making machine price but also long-term operating efficiency and cost control. A balanced solution that optimizes both equipment configuration and operational cost usually provides better long-term value than simply choosing the highest-priced option.