wood chipper for sale

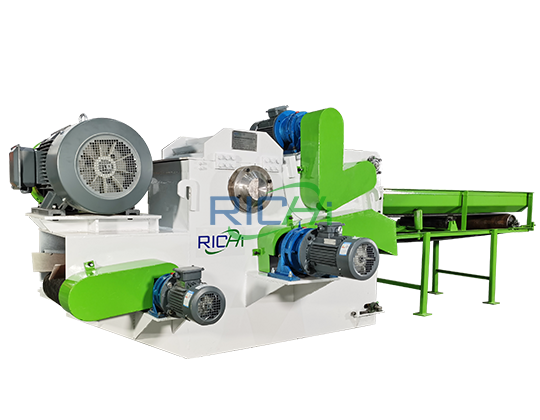

Wood chipper is designed for high efficiency, safety, and durability, which process logs, branches, or wood scraps into quality chips for further wood pellet processing. For customers looking for a reliable wood chipper for sale, our equipment provides the ideal solution to support pellet production lines with stable output and consistent chip quality.

What is a wood chipper?

RICHI’s wood chipper for sale is designed to process logs, felled wood, and residual materials (such as branches, tops, roots, and small-diameter logs) into 2-3 cm flakes for subsequent crushing and pelletizing.

Unlike conventional cutting tools, the RICHI drum wood chipper machine boasts a rational design and high efficiency. It incorporates powerful blades, an efficient feed system, and durable construction, enabling efficient processing of large volumes of wood.

RICHI MACHINERY

key Features of RICHI wood chipper for sale

Now that we’ve gained a basic understanding of the basic uses of a wood chipper, let’s delve deeper into its specific features. With meticulous design and premium build quality, this wood chipper excels in performance, durability, and ease of use. Below, we’ll detail these core features to give you a comprehensive understanding of how this machine efficiently handles a wide range of wood processing needs.

- The chippers for wood consists of a base, a cutter drum, upper and lower feed mechanisms, a feeding device, a hydraulic buffer system, and an electrical control system.

- The blades are made of a special material for high strength and wear resistance.

- The cutter drum is machined as a single unit and dynamically balanced for improved accuracy and smooth operation.

- The pressing system is hydraulically controlled, and the feeding system is frequency-controlled.

- The patented cutter drum structure increases slicing efficiency by 30%-50% and reduces main power consumption by 30%-50%, significantly reducing operating costs.

Why Choose Our best Wood Chipper?

RICHI Machinery’s wood chipper for sale is more than just a piece of equipment. It’s a crucial tool for protecting your investment and improving overall production efficiency. Due to its carefully designed functions, the equipment has significant advantages in efficiency, stability and economy, allowing users to achieve higher productivity, lower costs and more reliable operating experience in wood pellet production line. Let’s take a closer look at the core advantages of this machine.

Smooth Operation with Reduced Noise and Vibration

The rotor undergoes rigorous factory balancing to ensure ideal concentricity between the rotor and the entire machine. This ensures smooth operation even at high speeds, preventing excessive vibration that could affect chipping performance or damage components.

Furthermore, smooth operation reduces noise and improves the operating environment. For customers who require long, continuous operations, this not only reduces wear on the equipment but also significantly extends its service life.

Sturdy, Stable, and Reliable Construction

The entire machine body is welded from high-strength steel plates, creating a thick and sturdy structure that not only withstands the shock and pressure of long-term continuous operation but also provides strong support.

Compared to equipment made of ordinary materials, this sturdy body significantly reduces the risk of deformation or cracking, ensuring stable operation even in high-intensity working environments, saving customers the cost of subsequent repairs and replacements.

Securely Secured Blades for Safer Operation

The blade’s stability is directly related to the safe operation of the equipment. We use specially designed high-strength bolts and a pressure-fastening structure to firmly secure the fly cutters to the rotor cutter drum, ensuring that the blades do not shift during high-speed operation.

This not only ensures accurate and stable cutting, but also effectively prevents safety hazards caused by loose blades. So that users can operate with confidence without worrying about downtime caused by equipment failure.

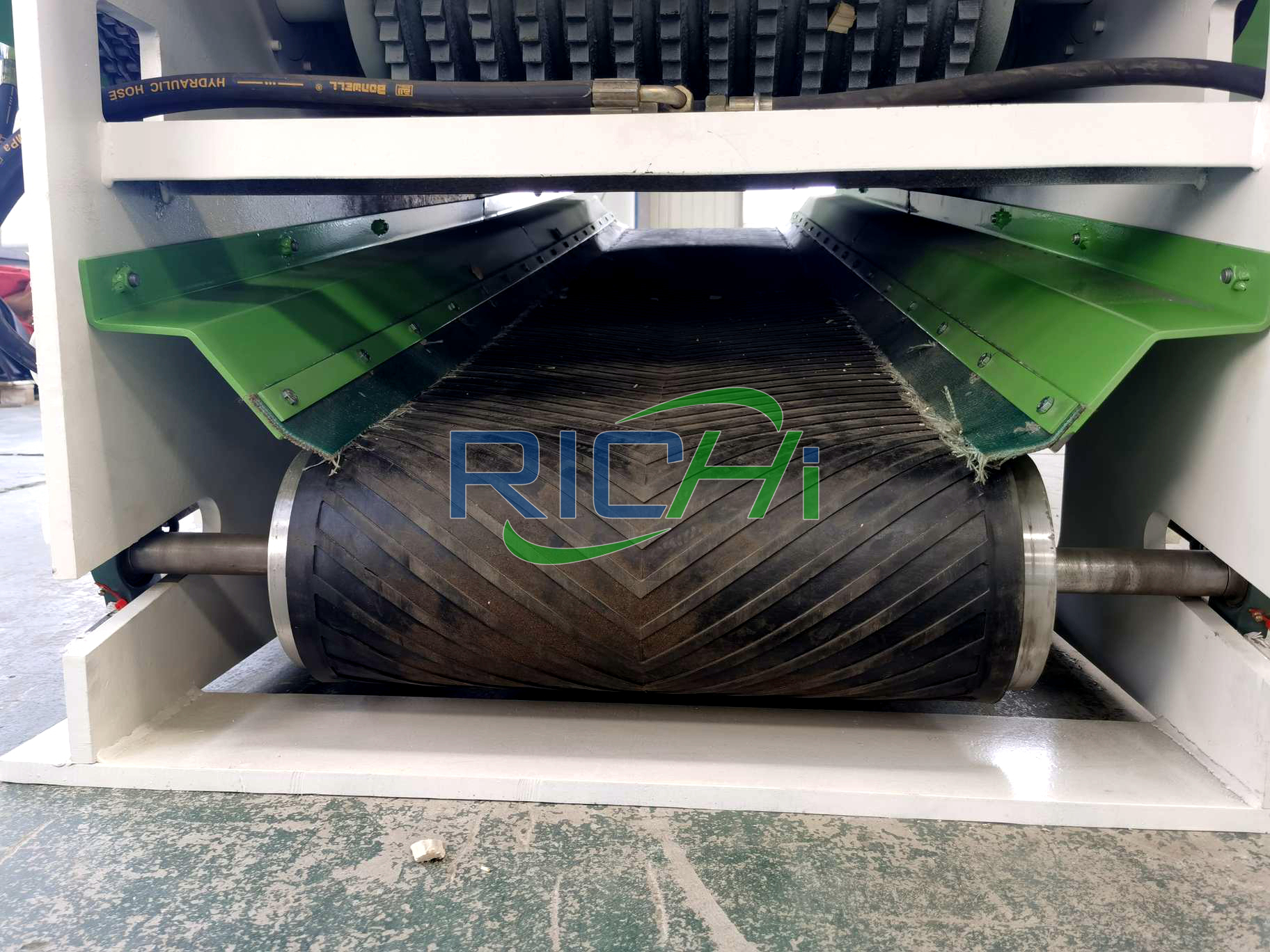

Intelligent Hydraulic-Assisted Feeding System

The machine is equipped with an advanced hydraulic-assisted feeding system. This design ensures the feed rollers securely grip the wood and evenly feed it into the chipping chamber, effectively preventing slippage, jamming, or backlash during the feeding process.

For users, this not only improves chipping efficiency but also ensures a continuous and stable production process, thereby increasing overall productivity.

High-Performance Cutting Tools with Long Wear Life

Both the fly cutters and the fixed cutters are made of high-quality 6GrW2Si alloy steel and undergo a professional high-temperature quenching process. This process significantly increases the hardness and wear resistance of the blades, making them suitable for woods of varying hardness and density.

Compared to conventional blades, they offer a longer lifespan and more consistent cutting performance. Even during high-load, continuous chipping operations, they maintain sharpness and efficiency, reducing the need for frequent blade changes.

Easy operation, simple maintenance, and low overall costs.

The machine’s compact and rational structure occupies a small footprint, making it easy to install and move. Furthermore, the machine’s design incorporates ease of maintenance, with components easily accessible for assembly and disassembly, making routine maintenance quick and simple.

Combined with stable operation and a low failure rate, overall maintenance costs are extremely low. While ensuring high output and quality, it helps users achieve a higher return on investment.

RICHI MACHINERY

Specifications & Parameters of wood chipper for sale

Understanding the technical specifications of your chosen equipment is crucial. RICHI Machinery offers a wide range of wood chippers to suit varying capacity requirements, raw material types, and production requirements. Each machine is meticulously designed for durability, efficiency, and uniform output, ensuring seamless integration with your project.

| Model | XPJ500x230 | XPJ680x300 | XPJ500*500 | XPJ850*500 | XPJ1200*500 | XPJ850*600 |

| Inlet Size (mm) | 500*230 | 680*300 | 500*500 | 850*500 | 1200*500 | 850*600 |

| Feed Size (mm) | φ230 | φ300 | φ500 | φ500 | φ500 | φ600 |

| Feed Motor Power (KW) | 4+3 | 4+3 | 4+3 | 4+3 | 5.5+4 | 7.5+7.5 |

| Main Motor Power (KW) | 75 | 90 | 110 | 132 | 200 | 200 |

| Hydraulic Pump Power (KW) | 0.75 | 1.1 | 1.5 | 1.5 | 1.5 | 3 |

| Outfeed belt power (KW) | 1.5 | 1.5 | 2.2 | 2.2 | 2.2 | 2.2 |

| Number of flying knives | 2 | 2 | 6 | 10 | 14 | 14 |

| Number of fixed knives | 1 | 1 | 2 | 3 | 3 | 3 |

If you need help to choose the right model, please contact us and tell us your daily output needs, we’ll recommend the best type match to you.

How Wood Chipper Ensures Efficiency and Quality in Pellet Production Line

A wood chipper is one of the key equipment in a wood pellet production line, primarily used to process logs, branches, and various wood waste materials into uniform chips. This process not only improves drying efficiency but also reduces energy consumption, ensuring efficient and smooth operation of subsequent processes. For example, in this 4-5 t/h biomass pellet production line, the industrial wood chipper cuts logs, branches, and scraps into uniform chips measuring 3-5 cm, which are then comminuted. This consistent size allows subsequent crushers, pelletizers, and other equipment to operate more efficiently and reduce energy consumption.

In the pellet production line, the main processes include chipping, crushing, drying, pelletizing, cooling and packaging. Among them, the RICHI wood chipper plays a vital role at the beginning.

First, larger raw materials, such as logs, branches, or wood waste, are fed into the chippers for wood, where they are chopped into uniform chips. This step is crucial, as oversized or irregularly shaped raw materials cannot be processed directly into the crusher or biomass pellet making machine. This processing ensures smoother and more efficient operation of the entire production line, which is why choosing the right wood chipper for sale is essential for pellet manufacturers.

After chipping, the wood chips enter a hammer mill for further comminution into fine sawdust. They are then dried in a dryer to an appropriate moisture content before being pelletized by a pelletizer. Finally, the pellets are sent to pellet cooler machine and then packaged for easy storage and distribution. Without this initial chipping process, subsequent production, high production capacity, and consistent pellet quality cannot be guaranteed.

Therefore, purchasing a high-performance wood chipper for sale can not only improve the efficiency of the entire production line, but also directly affect the final quality of wood pellets.

Frequently Ask Question

Before making an investment, customers often have many questions regarding performance, operation, and maintenance. To help you make an informed decision, we’ve compiled a list of the most frequently asked questions

What is a wood chipper and how does it work?

A wood chipper is a specialized machine that efficiently shreds large pieces of wood, branches, and other raw materials into 2-3 cm chips. The raw material is fed into an inlet, where rotating blades, cutters, or hammers rapidly cut or pulverize the wood into uniform particles.

The chipping process in the wood pellet or biomass pellet production line prepares for the subsequent drying and pelletizing processes, effectively improving production efficiency to a certain extent.

What types of wood can be processed by this machine?

RICHI wood chippers are versatile and can process a wide range of wood types, including softwoods such as pine, fir, cedar, and spruce, as well as hardwoods such as oak, maple, beech, and birch. They can also chop branches, small-diameter logs, bamboo, and various garden or forestry waste.

It’s important to check the maximum wood diameter a specific chipper model can handle. We offer different models depending on the size or hardness of the material. Choosing the right equipment ensures smooth operation, prevents damage, and maintains long-term performance.

What is the capacity of a typical wood chipper?

RICHI wood chipper for pellet production lines has a production capacity range of 3 to 18 tons per hour (T/H), depending on the machine model and feedstock type. These machines are specifically optimized to produce uniform chips suitable for drying and pelletizing, ensuring smooth and efficient operation of downstream pellet mills.

Small models (3–5 T/H) are ideal for small-scale pellet production, efficiently processing branches and softwood logs. Medium models (6–12 T/H) are suitable for commercial pellet mills, ensuring a stable supply of chips. Large industrial models (up to 18 T/H) meet the high-volume, continuous operation demands of large-scale pellet production lines, ensuring consistent pellet size and ultimately improving final pellet quality.

how do I choose the right model?

Choosing the right wood chipper for sale depends on several key factors related to your raw material, production requirements, and long-term business goals.

- Wood Type and Diameter: Determine the type and size of your raw material. We offer different models based on whether you’re processing softwood or hardwood, as well as the maximum log diameter.

- Capacity Requirement: Choose a different machine based on your daily or hourly production needs. We can also customize solutions based on your production needs.

At RICHI, our technical team provides customized recommendations based on your raw material and pellet production line design, ensuring that the model you choose perfectly matches your project.

Any Question?

We hope these FAQs have answered your main concerns. But every project is different, and you may still have specific questions about capacity, raw materials, or production line design. Don’t worry—we’re here to help. You can ask anything you want to know about Feedback.

RICHI MACHINERY

WHY CHOOSE US?

Selecting the right equipment suppliers is key to achieving stable production and long-term profitability. As an industry-leading manufacturer, RICHI MACHINERY combines decades of experience, advanced technology, and a global service network to deliver equipment that meets customer needs and customizes production lines. The following three core advantages will demonstrate why thousands of global clients choose to partner with us.

Strict quality standards and rich experience

With over 20 years of experience in industrial wood chipper manufacturing, we have served thousands of customers worldwide across more than 120 countries and regions.

Our reputation stems from strict international quality standards, with all products certified by ISO, CE, SGS and other international certifications, ensuring stable performance and reliable quality.

Customized wood chipping scheme

We customize wood chipper solutions and pellet equipment products for each customer, with advanced technology and professional design services, covering the whole process support from manufacturing, delivery to installation and training.

Each solution aims to help customers achieve efficient, intelligent and sustainable production.

Comprehensive after-sales service guarantees long-term operation

Our commitment extends beyond equipment supply to include rapid response after-sales services covering everything from initial consultation to long-term maintenance.

By choosing our wood chipper for sale, you are choosing a lasting partnership built on trust, responsibility, and proven expertise. Contact us now for customized solutions and quotations that can take your production to the next level.