Peanut Shell Pellet Machine

Peanut shell pellet machines transform low-density shells into high-value biomass fuel with stable performance and high output. With optional conditioning systems, the same equipment can also be adapted for feed production, offering flexible use across different industries.

What is the Peanut Shell Pellet Machine?

The peanut shell pellet machine is a high-efficiency biomass pellet making machine designed to compress loose, low-density peanut shells into high-density biomass fuel pellets. Peanut shells are abundant in agricultural production, but for a long time they have been discarded, burned in the open, or used inefficiently, resulting in resource waste and environmental pollution.

By compressing peanut shells into standardized fuel pellets, users can convert waste into high-value, environmentally friendly, and widely demanded clean energy, applicable to various fuel scenarios such as home heating stoves, industrial biomass boilers, steam systems, and biomass power plants.

During the production process, peanut shells are extruded under high pressure through a ring die. The lignin contained in the peanut shells softens under high temperature and pressure, becoming a natural binder, allowing the final pellets to be formed without any additives. The pellets are high in density, have a smooth surface, and are durable for storage. The finished pellets typically have a calorific value of 3800–4800 kcal/kg, low ash content, stable combustion, and clean emissions, making them a high-quality biomass energy source to replace traditional fuels such as coal, firewood, and diesel.

While the primary purpose of a peanut shell pellet machine is to produce fuel pellets, it can also be equipped with a steam modulator and specialized feed formulations to produce feed pellets if needed. For example, the starch curing level can be adjusted to improve palatability for different animals.

For users looking to turn agricultural waste into valuable resources and create sustainable energy benefits, peanut shell pellet mills are an ideal choice that combines efficiency, environmental friendliness, and commercial value.

Working Video Of Peanut Shell Pellet Machine

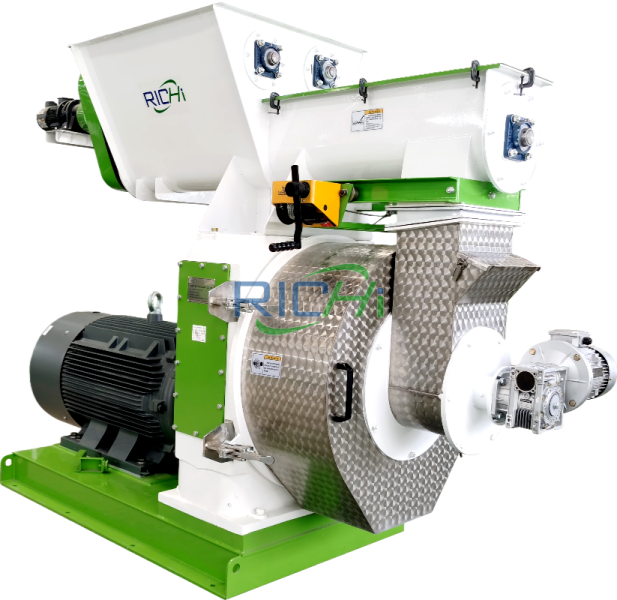

To help you better understand the performance and structure of our peanut shell pellet machine, we have prepared two demonstration videos. The first video offers a clear view of the machine’s exterior, build quality, and key components, while the second showcases the actual pelletizing process, allowing you to see how peanut shells are efficiently transformed into clean, dense biomass fuel.

Core Component Of Peanut Shell Pellet Machine

The performance and lifespan of a peanut shell pellet machine largely depend on the structural design and manufacturing quality of its core components. Because peanut shells are highly fibrous and abrasive, key components such as the ring die system, gearbox, bearings, and feeding mechanism must possess sufficient strength, precision, and wear resistance to ensure continuous, high-density fuel pellet compression.

Key technical characteristics of Peanut Shell Pellet Machine

The peanut shell pellet machine is built with several key technical features that ensure stable performance, high output, and long-lasting durability when processing hard and abrasive biomass materials such as peanut shells. These characteristics directly determine the machine’s compression strength, energy efficiency, and operational reliability, making it ideal for continuous biomass fuel pellet production.

Different Models & Specifications With Peanut Shell Pellet Machine

Choosing the right pellet mill model is crucial when producing peanut shell pellet fuel. Peanut shells, as a lightweight agricultural byproduct, have low bulk density and high fiber content; therefore, different target yields and production intensities will influence equipment selection. For biomass pellet fuel plants of varying sizes, RICHI Machinery offers a variety of equipment models with different power configurations, ring die sizes, and hourly output levels. The following content will visually demonstrate the parameters of each model to help users accurately assess performance and select the equipment best suited to their needs.

MZLH320 Small Peanut Shell Pellet Machine

- Main motor power (kW): 22

- Arch-breaking feeder power (kW): 2.2

- Forced feeder power (kW): 0.75

- Ring die inner diameter (mm): 320

- Output (T/H): 0.2-0.3

MZLH350 Peanut Shell Pellet Mill

- Main motor power (kW): 37

- Arch-breaking feeder power (kW): 2.2

- Forced feeder power (kW): 0.75

- Ring die inner diameter (mm): 350

- Output (T/H): 0.3-0.5

MZLH420 Pellet Machine For Peanut Shell

- Main motor power (kW): 90

- Arch-breaking feeder power (kW): 3

- Forced feeder power (kW): 1.5

- Ring die inner diameter (mm): 420

- Output (T/H): 1-1.2

MZLH520 Peanut Shell Pellet Making Machine

- Main motor power (kW): 132

- Arch-breaking feeder power (kW): 3

- Forced feeder power (kW): 1.5

- Ring die inner diameter (mm): 520

- Output (T/H): 1.5-2

MZLH678 Peanut Shell Pellet Machine

- Main motor power (kW): 185

- Arch-breaking feeder power (kW): 3

- Forced feeder power (kW): 1.5

- Ring die inner diameter (mm): 673

- Output (T/H): 2.5-3

MZLH768 Industrial Peanut Shell Pellet Machine

- Main motor power (kW): 250

- Arch-breaking feeder power (kW): 4

- Forced feeder power (kW): 1.5

- Ring die inner diameter (mm): 762

- Output (T/H): 3-4

How to Produce Peanut Shell Pellets

Producing high-quality peanut shell pellets requires a scientifically sound processing procedure to transform lightweight agricultural waste into dense, clean biomass fuel. Peanut shells are high in fiber and have a low bulk density, but a standardized pelleting process—crushing, drying, pelleting, cooling, screening, and packaging—can ensure stable pellet formation and consistent quality.

1

Raw Material Collection and Preparation:

Peanut shells are gathered from processing sites and screened to remove stones, dust, and other impurities. Proper pre-processing ensures smooth feeding and protects downstream equipment.

2

Crushing Section:

The shells are crushed into 3–5 mm particles using a hammer mill to achieve uniform size. Consistent particle size ensures efficient compression during pelletizing.

3

Drying Section:

The moisture content is adjusted to the ideal 12–18% to support proper pellet formation. Drying stabilizes the material and improves final pellet strength.

4

Pelletizing Section:

The prepared material enters the peanut shell pellet machine, where rollers press it through the ring die to form dense pellets. High temperature and pressure allow natural fiber bonding without additives.

5

Cooling and Screening:

Fresh pellets are cooled to harden their structure and improve durability. They are then screened to remove fines and ensure consistent quality.

6

Packing Section:

Finished pellets are packed into bags for easy handling, storage, and distribution. Proper packaging also protects the pellets from moisture.

Global Cases Of RICHI Peanut Shell Pellet Machine

With over 30 years of industry experience, RICHI Machinery has successfully delivered peanut shell pellet machines and related biomass pellet equipment products to more than 140 countries and regions. These examples not only demonstrate the reliability of RICHI equipment but also showcase the global trust and proven performance of our solutions in biomass fuel production and feed pellet processing. Our equipment is widely used in biomass processing plants and commercial fuel projects, offering stable operation and reliable output, helping customers convert agricultural waste into clean, economical biomass fuel. The following case studies demonstrate how different customers have used RICHI equipment to meet local energy needs and achieve efficient production.

Peanut Shell Pellet Making Machine for sale Nigeria

- Production Capacity: 1-1.5T/H

- Project Country: Nigeria

- Project Background: The client in Nigeria runs a medium-size agro-processing facility and generates large volumes of peanut shells every season. To reduce waste and create extra value, they decided to convert these shells into fuel pellets and chose RICHI’s 1–1.5TPH pellet solution for stable production.

- Client Feedback: The client reported high forming rate, low energy consumption, and easy daily operation. They also appreciated RICHI’s remote technical support, which made installation and startup smooth.

Peanut Shell Pellet Machine for sale india

- Production Capacity: 2T/H

- Project Country: India

- Project Background: Located in Gujarat, India, the customer has abundant peanut shell resources and planned to expand into the biomass fuel market. They selected RICHI’s 2TPH pellet line to produce stable, high-density pellets for industrial users.

- Client Feedback: The customer praised the pellet quality and stable operation of the system, noting that automation helped cut labor costs. They said the return on investment was faster than expected.

Peanut Shell Pellet Machine for sale indonesia

- Production Capacity: 3T/H

- Project Country: Indonesia

- Project Background: This Indonesian client wanted to reduce dependence on purchased pellets and use local peanut shells to build their own supply chain. They chose RICHI’s 3TPH biomass pellet line in Indonesia due to its strong performance with high-fiber materials.

- Client Feedback: The client reported excellent efficiency, minimal blockage issues, and strong market acceptance of the produced pellets. They also recognized RICHI’s professional technical guidance during commissioning.

Peanut Shell Pellet Mill for sale Bengal

- Production Capacity: 20T/H

- Project Country: Bengal

- Project Background: A large energy biomass pellet making plant in Bangladesh sought a high-capacity pellet system using peanut shells as their main material. After evaluating multiple vendors, they selected RICHI’s 20TPH multi-line solution for its stability and automation level.

- Client Feedback: The client was satisfied with the steady output, uniform pellet quality, and efficient multi-line coordination. They also praised the on-site training and commissioning support provided by RICHI engineers.

Why Choose Our Peanut Shell Pellet Mill

Choosing a reliable peanut shell pellet machine is key to achieving efficient, stable, and profitable pellet production. As a leading pellet equipment product manufacturer, RICHI’s equipment is trusted by users worldwide for its durability, precision engineering, and ability to process fibrous biomass materials such as stalks, leaves, and residues.

Superior Manufacturing & Guaranteed Quality

Each peanut shell pellet machine is built using high-strength alloy steel and precision CNC machining to withstand the abrasive and high-fiber characteristics of peanut shells. RICHI implements strict quality inspection processes and complies with global certification standards such as CE, ISO, and SGS. This ensures safe operation, low failure rates, and an extended service life, making our equipment a dependable choice for continuous biomass fuel production.

Optimized Design for Peanut Shell Pelletizing

Addressing the characteristics of loose, fibrous, and low-density peanut shells, the equipment features enhanced designs in the feeding, conditioning, compression, and discharge stages to effectively prevent bridging and blockage. RICHI also offers a variety of customized configurations, including modulators, coolers, dust removal systems, and automatic packaging machines, to help users create a pelleting production line that perfectly meets their fuel production needs and budget.

Rich Industry Experience and Trusted Reputation

With over 30 years of experience, RICHI Machinery has successfully delivered pellet production projects in more than 140 countries. Whether it’s a medium-to-large farm or a factory of any size, our engineering team provides complete project planning, installation, commissioning, and after-sales support. RICHI Machinery turnkey service delivers more than just equipment; it provides customers with a comprehensive, efficient, and profitable pellet production solution.

FAQ

To help customers better understand the operation, configuration options, and maintenance requirements of the peanut shell pellet making machine, we have compiled a list of the most frequently asked questions. Whether you are new to biomass pellet production or planning to upgrade your existing plant, these answers will provide clear guidance and practical information to support your decision-making.

What is the required moisture content of peanut shells before pelletizing?

+

For smooth pelletizing, peanut shells usually need to be dried to a 12–18% moisture content. Within this range, the material has enough flexibility to bind well during compression, while still being dry enough to prevent slippage or die blockage. If the shells are too wet, they tend to clog the die and produce soft pellets; if they are overly dry, they become powdery and difficult to form. Proper moisture control is one of the key steps to achieving stable output and consistent pellet quality.

Can the machine also produce other biomass pellets?

+

Yes, the peanut shell pellet machine is highly versatile and can process a wide variety of biomass materials beyond peanut shells. By adjusting the ring die, roller pressure, and feeding system, it can handle rice husk, sawdust, straw, sunflower husk, palm fiber, and other agricultural residues. This flexibility allows users to produce not only fuel pellets but also mixed-material biomass pellets, expanding production possibilities and potential revenue. The machine’s robust design and optimized compression system ensure that even fibrous or low-density materials can be pelletized efficiently, maintaining consistent pellet quality across different raw materials.

Can the machine be used for animal feed pellet production?

+

Yes, the peanut shell pellet machine can be adapted for producing animal feed pellets, making it suitable for medium to large-scale farms and animal feed pellet production line. By adding a conditioner and selecting the appropriate ring die, the machine can process grains, soybean meal, corn, and other feed ingredients. For farms or factories that plan to produce both fuel pellets and animal feed pellets, it is recommended to use two separate machines — one dedicated to biomass fuel and another for feed — to ensure optimal performance, prevent cross-contamination, and maintain consistent pellet quality. The optimized feeding and pelletizing system ensures stable operation and uniform pellet size across all applications.

How much does a peanut shell pellet machine cost?

+

The price of a single peanut shell pellet mill varies depending on its intended use and capacity. For fuel pellet production, a standalone pellet mill typically costs between USD 10,000 and 90,000, depending on the motor power, ring die size, and optional features. For animal feed pellet production, the price of a single machine usually ranges from USD 7,000 to 85,000, as additional components like a conditioner may be included. These prices do not cover full production lines, which would require extra equipment such as crushers, dryers, coolers, and packaging systems.

How do I choose the right machine for my production needs?

+

Choosing the right peanut shell pellet machine depends on several key factors.

- Intended Use: Determine whether the machine is primarily for fuel pellets or animal feed pellets, as this affects the machine’s configuration, accessories, and die type.

- Raw Material Characteristics: Assess your raw materials’ moisture content, hardness, and fibrous content. Some machines are better suited for high-fiber or low-density materials, while others handle softer or mixed biomass more efficiently.

- Production Capacity: Match the machine’s output to your daily or annual production goals. Consider whether you need continuous operation for medium to large-scale production.

- Local Electricity and Power Supply: Check the voltage, frequency, and power availability in your area to ensure the machine operates safely and efficiently.

- Budget and Investment: Set a realistic budget that includes the cost of the machine, optional accessories, installation, and maintenance.

- Manufacturer Selection: Choose a reliable manufacturer with proven experience, certifications, and good after-sales service to guarantee smooth installation, operation, and long-term support.