Fish Feed Extruder Machine Price

Fish feed extruder machine prices range from $3,000 to $200,000 according to brand, type, model, capacity and configuration. It can produce sinking fish, floating fish, shrimp, crabs and other aquatic feed and pet feed. If you want to buy a machine for producing fish feed or pet food, you can contact us.

What Is The Fish Feed Extruder Machine?

A fish feed extruder machine is a specialized device designed to produce high-quality aquatic feed and pet feed pellets efficiently. Unlike traditional pellet mills, which rely mainly on mechanical compression, a fish feed extruder uses high temperature, high pressure, and mechanical shear to cook raw materials and form pellets. This process improves digestibility, water stability, and nutrient availability, making it suitable for various fish species.

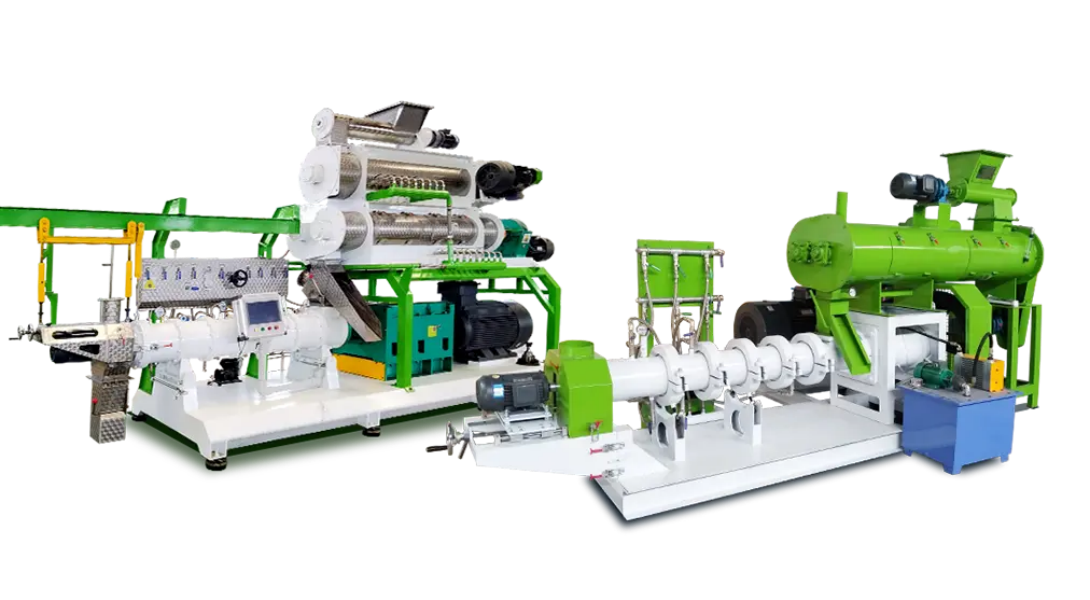

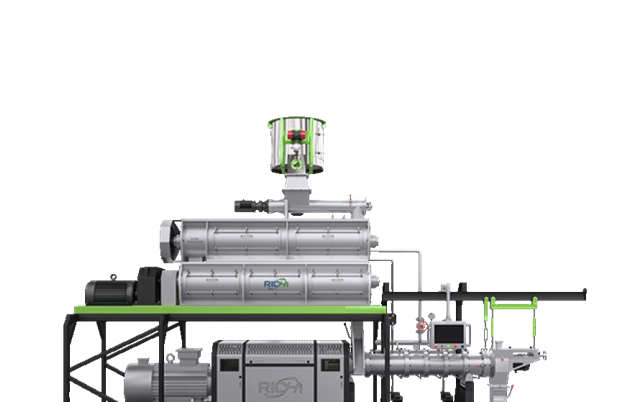

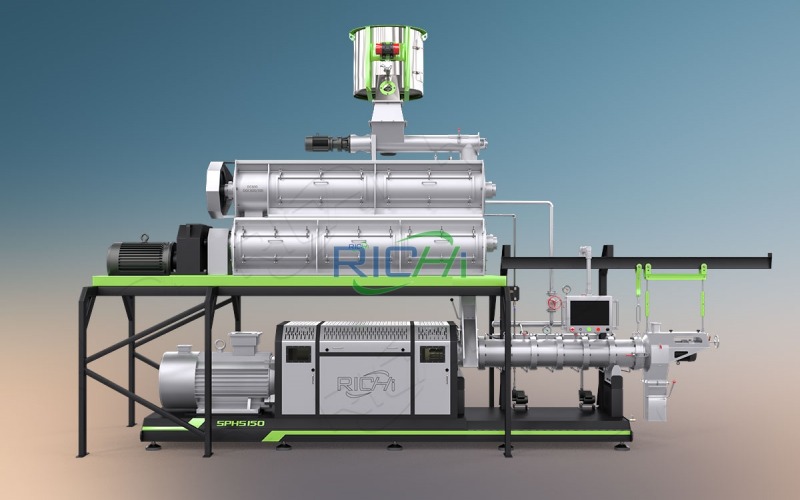

RICHI fish feed extruders are commonly divided into two types: single-screw and twin-screw extruders, each suited for different production needs and budgets.

- Single-Screw Fish Feed Extruder: A single-screw extruder has a single rotating screw that moves and compresses raw materials inside a barrel before forcing them through a die. It is simple, cost-effective, and easy to maintain. Generally, single-screw fish feed extruder machine price ranges from about USD 3,000 to 40,000.

- Twin-Screw Fish Feed Extruder: A twin-screw extruder features two intermeshing screws, providing more intensive mixing, cooking, and shearing of raw materials. This type is ideal for large-scale feed production and complex feed formulas. Its price ranges from USD 70,000 to 200,000.

Fish feed extruders are widely used in commercial feed plants, aquaculture farms, research facilities, and export-oriented feed production. They help improve fish growth, survival rates, and feed efficiency.

Different Fish Feed Extruder Machine Price With Different Parameter

When selecting a fish food extruder, it is important to consider the type and capacity that best fit your production needs. This will help you understand the features, production capabilities, and estimated fish feed extruder machine price for each model, allowing you to make an informed decision for your farm or feed mill.

Single-Screw Fish Feed Extruder

- Produces floating or sinking pellets for small to medium farms

- Handles standard raw materials such as corn, soybean, wheat, and fish meal

- Lower initial investment with stable performance

| Model | SPHS75x2 | SPHS120*2 | SPHS150*2 | SPHS185*2 | |

| Main Motor Power | 55KW | 90KW | 110KW | 200KW | 355KW |

| Feeder Power | 1.5KW | 1.5KW | 1.5KW | 1.5KW | 2.2KW |

| Output | 0.5-1.0T/H | 1.5-2.0T/H | 3.0-4.0T/H | 5.0-6.0T/H | 8-10T/H |

| Guide Price | 3,000 – 15,000 USD | 10,000 – 25,000 USD | 20,000 – 35,000 USD | 30,000 – 40,000 USD | 35,000 – 40,000 USD |

Twin-Screw Fish Food Extruder

- Handles high-fat, high-protein, and sticky materials

- Precise control of temperature, moisture, and pressure

- Supports floating, slow-sinking, and sinking pellets

- Higher production capacity and flexibility

| Model | DGP-90B | DGP-120B | DGP-160B | DSP-90B | DSP-135B |

| Main Motor Power | 37 | 55 | 90 | 37 | 75 |

| Feeder Power | 0.75 | 202 | 3 | 7.5 | 7.5 |

| Output | 0.2-0.4T/H | 0.5-0.6T/H | 0.8-1.0T/H | 0.5-0.6T/H | 0.8-1.0T/H |

| Tempering Power | / | / | / | 1.1 | 2.2 |

| Guide Price | 70,000 – 90,000 USD | 95,000 – 120,000 USD | 120,000 – 160,000 USD | 100,000 – 140,000 USD | 150,000 – 200,000 USD |

How to Choose the Right Model?

After reviewing the technical specifications and capacity parameters, the next step is selecting the most suitable model based on actual production requirements. As the main machine of fish feed pellet production line or fish feed plant, the properly selected machine can ensure stable feed quality while keeping the overall fish feed extruder machine price reasonable and cost-effective in long-term operation. In real projects, different customers choose different fish feed extruder models according to their production scale, feed formulation, and investment goals.

Based on Production Scale and Capacity Requirements

Production capacity is usually the primary factor when selecting a fish feed extruder model. Medium-scale farms or newly established projects typically prefer single screw extruders with moderate output and stable performance. Medium and large commercial feed plants, on the other hand, often require twin screw extruders to support continuous and high-capacity production.

Based on Feed Type and Formula Complexity

Different fish feed formulas place different requirements on extrusion performance. Single screw extruders are suitable for conventional feed formulas with relatively stable raw material composition. Twin screw extruders, however, provide stronger mixing, cooking, and processing capabilities, making them more suitable for high-protein, high-fat, or complex feed formulations.

Based on Budget and Long-Term Operating Cost

When selecting a fish feed extruder, initial investment should always be evaluated together with long-term operating costs. Single screw extruders usually require lower upfront investment and simpler maintenance. Twin screw extruders involve a higher initial cost, but offer greater production flexibility and efficiency over long-term operation.

Based on Automation Level and Future Expansion Plans

Future production plans should also be considered during model selection. For projects with potential expansion, choosing a model with higher automation and scalability can reduce future upgrade costs. For fixed-capacity production lines, a standard configuration may provide a more economical solution.

RICHI MACHINERY

Different Fish Feed Extruder Machine Price In Global Project Cases

RICHI Machinery has completed a lot of sales of fish feed pellet making machines at home and abroad, and helped customers build fish feed plants. Our projects have covered 140+ countries and regions. Fish feed pellet machine price varies significantly across global project cases due to differences in raw materials, required pellet type, automation level, and production capacity. By reviewing real installations from different countries, buyers can better understand how local farming practices, feed formulas, and market scales influence equipment selection and overall investment.

500KG fish Feed Production Line

- Country: Iran

- Guide Price: $80,000

- Raw Materials: Corn, soybean meal, wheat flour, fish meal, vitamin and mineral premix.

- Project Background: A feed processing company in Iran planned to establish a small to medium-scale production line for both fish feed and pet food. The goal was to produce stable-quality feed pellets for local aquaculture farms and the regional pet food market.

- Selected Solution: A single screw fish extruder machine was selected to meet the production capacity and formulation requirements. The configuration focused on stable extrusion performance and easy operation.

- Project Result: The production line achieved stable operation and consistent pellet quality, meeting the customer’s expectations for both fish feed and pet food production.

1-2T/H Floating Fish Feed Production Line

- Country: Russia

- Guide Price: $440,000

- Customer Requirements: continuous commercial production

- Project Background: A commercial floating fish feed plant in Russia aimed to expand its aquaculture feed capacity to supply floating fish feed to large-scale fish farms. High output and continuous production were key project goals.

- Selected Solution: A twin screw fish feed extruder was selected to support high-capacity output and better cooking and mixing performance. The system was designed for long-term, stable operation.

- Project Result: The production line achieved stable high-output operation and produced floating pellets with uniform shape and density, supporting large-scale aquaculture supply.

2T/h Shrimp Feed Making Machine In Indonesia

- Country: Indonesia

- Guide Price: $455,000

- Raw Materials: Fish meal, soybean meal, wheat flour, shrimp feed additives.

- Project Background: An aquaculture-focused customer in Indonesia planned to produce shrimp feed for local shrimp farms, aiming to improve feed quality and reduce reliance on external suppliers. During the planning stage, the customer carefully evaluated the fish feed extruder machine price in relation to production capacity, feed quality requirements, and long-term operating costs

- Selected Solution: Based on the formulation characteristics and production requirements, a suitable fish feed extruder configuration was selected to ensure proper cooking and pellet quality for shrimp feed.

- Project Result: The shrimp feed production line operated smoothly and produced pellets suitable for shrimp feeding, supporting local aquaculture production needs.

1T/H Floating Fish Feed Production Line

- Country: Qatar

- Guide Price: $155,000

- Raw Materials: Corn, wheat, soybean meal, fish meal, functional additives.

- Project Background: The customer invested in fish feed manufacturing plant to support intensive aquaculture systems with strict quality and hygiene requirements.

- Selected Solution: A 1T/H floating fish feed extruder system was designed with automated control and optimized layout for stable operation.

- Project Result: The floating fish feed extruder machine provided consistent floating pellets and improved feed supply reliability.

5T/H Fish Feed Mill Plant

- Country: Russia

- Guide Price: $680,000

- Raw Materials: Corn, wheat, soybean meal, fish meal, oil additives.

- Project Background: This Russian customer is a commercial feed manufacturer supplying fish feed to regional aquaculture farms. The project required continuous production, high automation, and consistent pellet quality for large-scale distribution.

- Selected Solution: We delivered a 5 t/h commercial fish feed plant with automated batching, centralized control, and high-capacity extrusion system designed for long-hour operation.

- Project Result: The plant achieved stable mass production with reduced labor costs and consistent product quality, enabling the customer to expand regional feed supply.

300-400KG Floating Fishing Feed Line

- Country: Indonesia

- Guide Price: $62,000

- Raw Materials: Corn, rice bran, soybean meal, fish meal.

- Project Background: The customer aimed to produce floating fish feed on-site to reduce feed costs and improve feeding flexibility.

- Selected Solution: A compact 300 kg/h fish feed pellet extruder machine was selected for easy operation and small footprint.

- Project Result: he customer achieved reliable on-farm feed production and better cost control.

Video Demonstration of Fish Feed Extruder Machine

To give a clearer understanding of our fish extruder machines in actual operation, we provide a series of demonstration videos. These videos showcase single screw and twin screw extruder machines, the pellet forming process, and complete production line operation.

By watching these demonstrations, you can see how production stability, pellet quality, and efficiency are achieved, helping you better evaluate the fish feed extruder machine price for your own project.

Why Choose Our Hemp Pellet Machine

When investing in a fish feed extruder machine, it is not enough to only consider the initial price. Long-term operation efficiency, maintenance requirements, and overall production costs are equally important. Some machines may have a low initial cost but frequently encounter operational issues, resulting in higher expenses over time.

As a leading pellet equipment product manufacturer, RICHI’s equipment is trusted by users worldwide for proven quality, professional service, and comprehensive support throughout the entire production process.

High-Quality Equipment

RICHI extruder machines are manufactured using premium materials and advanced engineering, ensuring stable operation, long service life, and minimal downtime.

Our machines have passed multiple international certifications, demonstrating compliance with global quality and safety standards.

Customized Solutions

Every feed production project has unique requirements. RICHI provides tailor-made fish feed extruder machine price and solutions according to your raw materials, feed types, and production capacity.

Whether single screw or twin screw extruders, small-scale or industrial lines, our engineers design each solution to optimize efficiency and minimize waste.

Full-Service Support

With RICHI Machinery turnkey service, we provide complete solutions including installation, commissioning, staff training, and ongoing technical support.

From project planning to after-sales service, we ensure smooth operation and help clients maximize ROI, giving investors confidence in long-term performance.

What Factors Affecting The Fish Feed Extruder Machine Price?

The fish feed machine price is not fixed and can vary significantly depending on multiple factors. By considering these factors carefully, you can select a machine that delivers both high performance and cost-efficiency.

1

Type of Extruder

Single-screw extruders are generally more affordable, ideal for medium to large farms. Twin-screw extruders are more expensive because they offer higher production capacity, better material adaptability, and advanced features.

2

Production Capacity

Machines with higher output naturally have a higher fish feed extruder machine price. Small-capacity extruders are cheaper, while large-scale machines designed for commercial feed plants require a higher investment.

3

Automation Level

Fully automated extruders with PLC control, automatic feeding, and monitoring systems improve efficiency but raise the cost. Semi-automatic or manual models are more budget-friendly.

4

Raw Material Compatibility

Extruders that can handle high-fat, sticky, or mixed ingredients typically have a higher fish feed machine price due to specialized screws, barrels, and heating systems.

5

Additional Equipment

Including dryers, coolers, conveyors, or pellet coating systems will increase the overall price. Buyers should consider which accessories are essential for their production process.

4

Brand and After-sales Service

Established brands with reliable after-sales support may cost more, but they provide long-term benefits such as technical guidance, spare parts availability, and reduced maintenance issues.

FAQ

To help you make a more informed investment decision, we’ve compiled a list of frequently asked questions from customers around the world. This FAQ section addresses common questions to help you make informed decisions and plan your investment with confidence.

Can the machine produce multiple types of feed simultaneously?

+

Yes, our twin screw fish feed extruder machine can produce multiple types of feed simultaneously, making it highly suitable for farms or feed manufacturers that raise different species such as tilapia, catfish, shrimp, or want to produce pet feed alongside aquaculture feed. Unlike single screw machines, twin screw extruders offer precise control over key parameters including screw configuration, barrel temperature, moisture content, and feed ratios. This flexibility allows the same machine to produce floating, sinking, specialty aquaculture feed, or pet feed without compromising pellet quality or nutritional value.

From an investment perspective, producing multiple feed types—including both aquaculture and pet feed—may slightly increase the initial fish feed extruder machine price, but the efficiency gains and reduced need for multiple machines make it cost-effective in the long run. Farms benefit from simplified production lines, consistent pellet size and density, and the ability to quickly adjust feed formulas based on species, growth stage, or market demand.

How much does invest in a complete fish feed mill plant cost?

+

Investing in a complete fish feed mill plant involves multiple factors, and the total cost is determined not only by the capacity of the plant but also by the types of feed you intend to produce, the raw materials used, and the level of automation. And it is essential to include auxiliary equipment such as mixers, dryers, coolers, conveyors, storage silos, and control systems.

Several key factors influence fish feed pellet machine price: the complexity of feed formulas (floating, sinking, specialty), desired pellet size and density, the level of automation for feeding and packaging, and the quality and certification of the equipment. In addition to equipment, other investment considerations include building construction, utility setup (electricity, water, and steam), training for operators, and spare parts inventory. A well-planned plant layout and an appropriately sized twin screw extruder ensure maximum throughput, high-quality feed production, and flexibility for future expansion.

How much should I expect to invest in a fish feed extruder machine for a mid-sized farm, and what factors influence the total cost?

+

When planning to invest in a fish feed extruder machine, the initial purchase price is only one part of the total investment. For a mid-sized farm, a small electric fish feed extruder machine price may between $3,000 and $40,000. However, the total investment should also account for additional equipment such as dryers, coolers, mixers, and storage systems.

The main factors influencing the price include the type of feed you plan to produce (floating or sinking), raw material types, desired pellet size and density, and the complexity of your formulas. For example, a shrimp or pet feed line requires more precise control of temperature, moisture, and extrusion pressure, which may slightly increase costs compared to standard floating fish feed.

In summary, the investment in a fish feed extruder machine is determined not only by the machine’s initial price but also by your farm’s production goals, feed types, raw materials, and long-term operational strategy. A well-planned investment ensures both high-quality feed production and cost-effective operations.

My farm mainly produces tilapia and catfish, and I want to make both floating and sinking feed. How does this affect cost?

+

o efficiently produce both floating and sinking feed, we recommend using a twin screw fish feed extruder machine. Twin screw extruders offer precise control over extrusion parameters, including screw configuration, temperature, moisture, and feed ratio, which allows you to produce multiple feed types simultaneously without compromising pellet quality or nutrient retention.

Regarding investment, a twin screw extruder typically ranges between $70,000 and $120,000 depending on capacity, die size, and motor power. When evaluating the fish feed extruder machine price, it’s important to consider not just the initial purchase cost but also the total investment in auxiliary equipment such as dryers, coolers, and mixers. This ensures consistent feed quality and operational efficiency, which ultimately reduces long-term costs.