EFB Pellet Machine

EFB pellet machine is specially designed for palm empty fruit bunch (EFB) waste, efficiently crushing, drying, and compressing it into high-density pellets. The resulting biomass pellets feature low moisture, high calorific value, and easy storage and transport, making them ideal for biomass power plants, industrial boilers, and fuel substitution solutions, turning waste into valuable energy while promoting energy efficiency and sustainability.

What Is The EFB Pellet Machine?

EFB pellet machine is a specialized biomass pellet making machine designed to compress loose palm empty fruit bunch fiber into dense and high-quality EFB fuel pellets. Empty fruit bunch fiber is one of the most abundant by-products of the palm oil industry, but due to its low bulk density and high moisture content, it has long been difficult to transport, store, and utilize effectively. Converting this agricultural residue into fuel pellets helps reduce waste and provides a clean and renewable source of energy.

When processing EFB materials, the machine uses a ring die under high pressure and high temperature to soften the natural lignin inside the fibers, allowing it to act as a binder during pellet formation. This process allows pellets to be produced without any chemical additives. The finished EFB pellets feature high density, uniform shape, strong durability, and a smooth surface, with a typical calorific value of 3500 to 4500 kcal per kilogram, making them a practical replacement for traditional fossil fuels.

EFB pellets produced by this machine can be widely used in biomass boilers, industrial furnaces, steam generation systems, drying equipment, and commercial heating. Their stable combustion, low ash content, and clean emissions make them an environmentally friendly fuel option for factories, palm oil mills, and biomass energy projects. In Southeast Asia and other palm-producing regions, EFB pellets have become increasingly popular due to their stable supply and economic benefits.

For palm oil producers, biomass energy investors, and renewable energy users, the EFB pellet machine offers an efficient solution to convert agricultural waste into valuable clean energy. It improves resource utilization, reduces storage and transportation costs, and generates long-term economic and environmental benefits.

Working Video Of EFB Pellet Machine

To help you better understand our EFB pellet machine, we have prepared two videos: the first shows the full exterior of the equipment, and the second demonstrates the actual pelletizing process. These videos allow you to clearly see the machine’s industrial-grade structure, as well as how it efficiently converts palm waste into high-quality biomass pellets during operation.

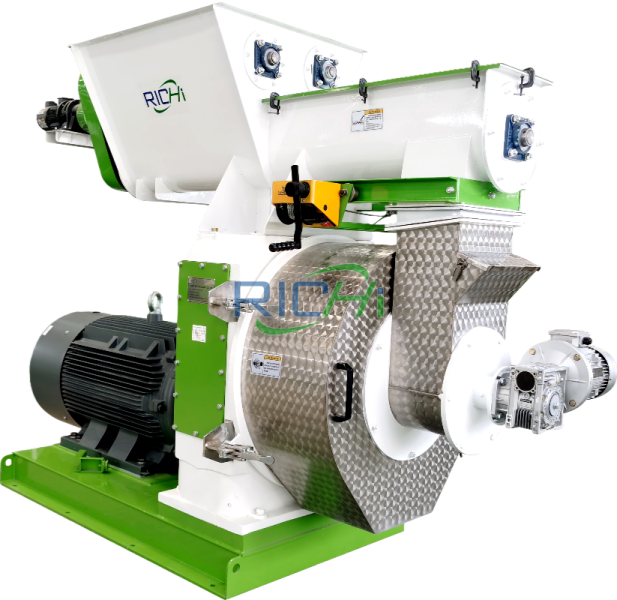

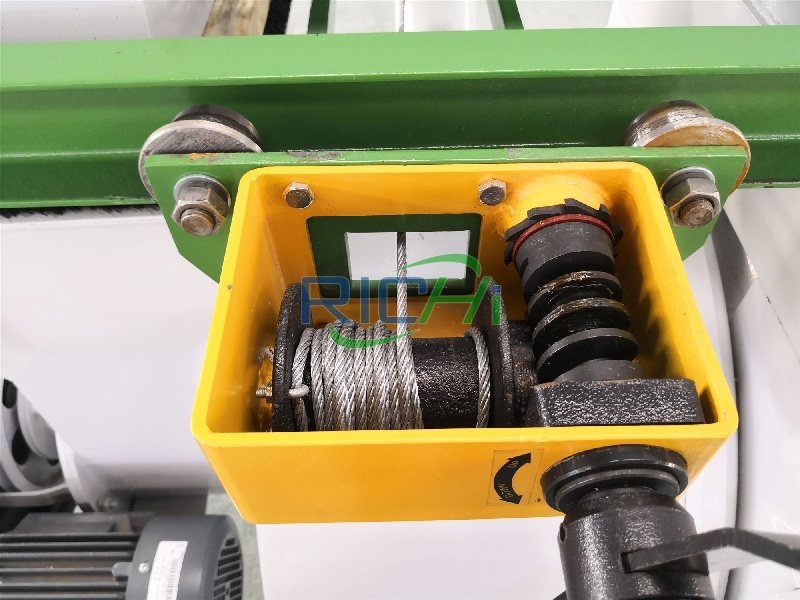

Core Component Of EFB Pellet Machine

The core components of the EFB pellet machine determine its stability, durability, and pelletizing performance. Below are several key parts of the equipment, allowing you to clearly see the structural design and manufacturing quality that ensure long-term, efficient pellet production.

Key Technical Characteristics Of EFB Pellet Machine

The EFB pellet machine is engineered to handle the unique properties of empty fruit bunch fibers, which are long, fluffy, and difficult to compress without proper processing. To ensure stable pelletizing, the machine integrates a series of specialized structural designs and technical features that enhance durability, efficiency, and pellet quality. These characteristics make the machine suitable for large-scale palm biomass processing and ensure consistent performance even under continuous heavy-duty operation.

Different Models & Specifications With EFB Pellet Machine

RICHI Machinery EFB pellet machines come in a range of models and specifications to meet the diverse needs of palm biomass processing. Different capacities, die sizes, and power configurations allow users to choose the most suitable machine according to their production scale, raw material characteristics, and energy requirements. Understanding the various models and technical specifications helps ensure optimal efficiency, consistent pellet quality, and long-term reliability for both small-scale and large-scale operations.

MZLH320 Small EFB Pellet Machine

- Main motor power (kW): 22

- Arch-breaking feeder power (kW): 2.2

- Forced feeder power (kW): 0.75

- Ring die inner diameter (mm): 320

- Output (T/H): 0.2-0.3

MZLH350 EFB Pellet Machine

- Main motor power (kW): 37

- Arch-breaking feeder power (kW): 2.2

- Forced feeder power (kW): 0.75

- Ring die inner diameter (mm): 350

- Output (T/H): 0.3-0.5

MZLH420 Pellet Machine For EFB

- Main motor power (kW): 90

- Arch-breaking feeder power (kW): 3

- Forced feeder power (kW): 1.5

- Ring die inner diameter (mm): 420

- Output (T/H): 1-1.2

MZLH520 EFB Pellet Machine

- Main motor power (kW): 132

- Arch-breaking feeder power (kW): 3

- Forced feeder power (kW): 1.5

- Ring die inner diameter (mm): 520

- Output (T/H): 1.5-2

MZLH678 EFB Pellet Machine

- Main motor power (kW): 185

- Arch-breaking feeder power (kW): 3

- Forced feeder power (kW): 1.5

- Ring die inner diameter (mm): 673

- Output (T/H): 2.5-3

MZLH768 Industrial EFB Pellet Machine

- Main motor power (kW): 250

- Arch-breaking feeder power (kW): 4

- Forced feeder power (kW): 1.5

- Ring die inner diameter (mm): 762

- Output (T/H): 3-4

How To Produce EFB Pellets

Producing EFB pellets involves a series of processes designed to transform loose, fibrous palm empty fruit bunches into dense and uniform fuel pellets. The production process not only increases the energy density of the raw material but also makes it easier to transport, store, and utilize as a clean biomass fuel. Understanding the main steps helps ensure high-quality pellets with stable combustion performance and minimal waste.

1

Raw Material Collection and Preparation:

Empty fruit bunches (EFB) are collected from palm oil mills and sorted to remove impurities.

2

Crushing Section:

The prepared EFB fibers are fed into a crusher to reduce their size. This step ensures uniform particle size, improves compression efficiency, and facilitates smooth feeding into the pellet machine.

3

Drying Section:

Crushed EFB may have high moisture content. A drying system reduces the moisture to an optimal level (usually 12–18%) for pelletizing, which ensures proper compaction and high pellet quality.

4

Pelletizing Section:

The dried EFB is fed into the pellet machine, where high pressure and temperature compress the fibers into dense pellets. The machine’s ring die and rollers are designed to produce uniform, durable, and smooth-surfaced pellets.

5

Cooling and Screening:

Hot pellets are transferred to a cooler to reduce temperature and harden them. After cooling, the pellets are sieved to remove fines and broken pieces, ensuring uniform size and quality.

6

Packing Section:

Finished EFB pellets are conveyed to a packing station, where they are bagged or bulk-packed for storage and transportation. Proper packaging maintains pellet integrity and facilitates handling.

Global Cases Of RICHI EFB Pellet Machine

With over 30 years of industry experience, RICHI Machinery has successfully delivered EFB pellet machines and related biomass pellet equipment products to more than 140 countries and regions.Our machines are widely used in palm biomass processing plants, helping clients convert empty fruit bunches into high-quality fuel pellets efficiently. These global projects demonstrate the reliability, versatility, and high performance of RICHI EFB pellet machines in diverse production environments.

EFB Pellet Machine For Sale Malaysia

- Production Capacity: 1.5-2T/H

- Project Country: Malaysia

- Project Background: This project is located in a palm oil plantation area in Malaysia, where empty fruit bunches (EFB) are abundant. The customer wanted to convert agricultural waste into high-value biomass fuel pellets for local heating and industrial use. RICHI provided a single EFB pellet machine with supporting accessories to ensure smooth production. The project was completed within 2 months, including installation and commissioning.

- Client Feedback: The customer was satisfied with the machine’s performance, noting stable production, uniform pellet quality, and low maintenance requirements. They appreciated RICHI’s responsive technical support during startup.

EFB Pellet Machine For Sale Romania

- Production Capacity: 2-2.5T/H

- Project Country: Romania

- Project Background: In Romania, the customer sought to utilize agricultural biomass efficiently and produce renewable energy pellets. The project required a medium-capacity EFB pellet machine suitable for local raw material conditions. RICHI delivered the machine with full installation and operator training within a 3-month project cycle.

- Client Feedback: The customer highlighted the machine’s adaptability to different biomass types, smooth operation, and consistent pellet density. They were impressed with the professionalism of the installation team.

EFB Pellet Machine For Sale Indonesia

- Production Capacity: 3-4T/H

- Project Country: Indonesia

- Project Background: Located in an industrial palm plantation area, this Indonesian project aimed to convert large volumes of EFB into fuel pellets for biomass boilers. The project is part of a fully customized biomass pellet line in Indonesia, designed to meet the client’s specific production requirements. It was completed efficiently within 3 months.

- Client Feedback: The customer praised the machine’s durability, high pellet density, and energy efficiency. They also valued the ongoing support and guidance provided by RICHI engineers.

EFB Pellet Machine For Sale Thailand

- Production Capacity: 3-5T/H

- Project Country: Thailand

- Project Background: This project in Thailand focused on sustainable energy production using abundant palm biomass. The client required a pellet machine capable of producing consistent, high-quality pellets for both local and export markets. This was a fully customized biomass pellet making plant project, tailored to meet the client’s specific production and operational requirements.

- Client Feedback: The client was very satisfied with the machine’s stable operation, low downtime, and consistent pellet quality. They highlighted RICHI’s professional service and timely technical support.

Why Choose Our EFB Pellet Machine

RICHI EFB pellet machines are designed to provide high efficiency, reliability, and long-term performance for biomass pellet production. With advanced engineering, robust construction, and international-quality components, our machines help clients convert empty fruit bunches into high-density, uniform fuel pellets with minimal maintenance. Choosing RICHI means investing in proven technology, consistent pellet quality, and excellent after-sales support.

Superior Manufacturing & Guaranteed Quality

RICHI Machinery produces pellet machines that meet international certification standards, including ISO and CE certifications, ensuring each unit is high-quality, durable, and reliable. Every component is precision-machined and undergoes strict quality control procedures to guarantee stable operation even under continuous heavy-duty use. Our machines are designed for long-term performance, minimal downtime, and low maintenance requirements, giving clients peace of mind and consistent pellet production.

Optimized Design For EFB Pelletizing

Our EFB pellet machines feature an optimized structure with reinforced rollers, adjustable ring dies, and high-strength gear transmission systems. This design ensures efficient compression of empty fruit bunches into uniform, high-density pellets with smooth surface, minimal fines, and stable combustion. The machines are easy to operate and maintain, making them suitable for various production scales.

Rich Industry Experience And Trusted Reputation

With over 30 years of experience, RICHI Machinery has successfully delivered pellet production projects in more than 140 countries. Whether it’s a medium-to-large farm or a factory of any size, our engineering team provides complete project planning, installation, commissioning, and after-sales support. RICHI Machinery turnkey service delivers more than just equipment; it provides customers with a comprehensive, efficient, and profitable pellet production solution.

FAQ

To help our customers better understand RICHI EFB pellet machines and their operation, we have compiled a list of frequently asked questions. This section provides clear and practical guidance to address common inquiries and assist users in making informed decisions.

What raw materials can the EFB pellet machine process, and can it produce pellets from mixed materials?

+

The machine is specially designed for empty fruit bunches (EFB), but it can also handle other fibrous biomass materials efficiently, producing uniform and high-density pellets. In addition, it can process mixed raw materials, allowing users to combine EFB with other biomass such as palm fronds, coconut shells, or agricultural residues to create customized pellets.

How much does an EFB pellet machine cost?

+

The cost of an EFB pellet machine depends on the model, production capacity, and any specific optional features. Generally, small-capacity machines start around US$10,000, while large-capacity machines can reach up to US$90,000. We provide customized quotations based on your raw material type, desired pellet size, and output, ensuring you choose the most suitable single-machine solution for efficient and profitable production.

What factors should I evaluate before investing in an EFB pellet production line to ensure profitability and smooth operation?

+

When planning an EFB pellet production investment, it is important to carefully evaluate several key factors. First, assess the availability and consistency of raw materials, as sufficient supply is critical for continuous production. Next, determine the desired production capacity to match market demand and ensure profitability. Energy consumption, labor requirements, and operational costs should also be analyzed to optimize overall efficiency. In addition, consider storage, transportation, and downstream applications for the pellets.

RICHI’s engineering team provides comprehensive support, including project planning, equipment selection guidance, installation, commissioning, and cost analysis. This helps investors make informed decisions, minimize risks, and achieve high returns on their investment.

How can I choose the right EFB pellet machine for my production needs?

+

To choose the right EFB pellet machine, start by assessing your raw material type, moisture content, and available supply. Then determine your desired production capacity and budget. Consider energy availability, maintenance requirements, and the intended pellet size for your applications. RICHI’s experts can provide personalized recommendations, helping you select a machine that ensures efficient production, reliable operation, and maximum return on investment.