Cassava Pellet Making Machine

A cassava feed pellet making machine is designed for producing pellets from cassava and cassava-based formulations, widely used in livestock and poultry feeding as well as certain plant-based cat litter applications. By pelletizing cassava materials, producers can improve palatability, digestion efficiency, pellet stability, and transportation convenience.

What Is The Cassava Pellet Making Machine?

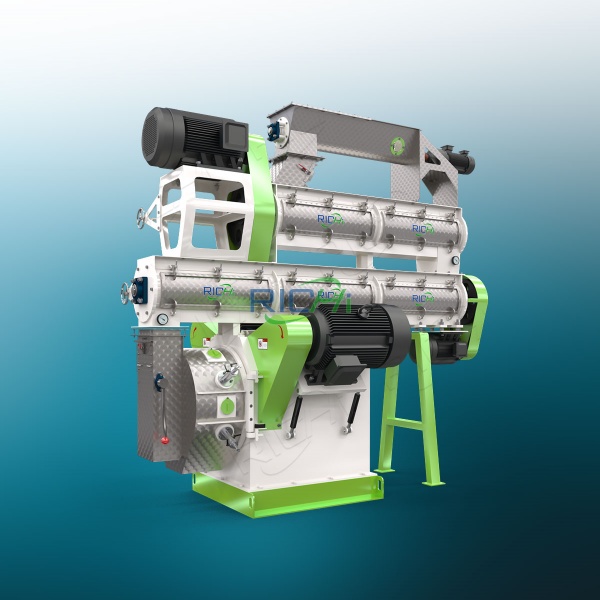

A cassava pellet making machine is a specialized pelletizing system designed to process cassava-based raw materials into compact and uniform pellets. It is primarily used in feed production, and can also be adapted for certain plant-based cat litter pellet applications that require stable pellet structure and consistent density.

The machine can process cassava chips, cassava flour, cassava peels, and mixed feed formulations. Cassava is a high-energy ingredient rich in carbohydrates and is widely used as a partial replacement for maize in animal feed. Through pelletizing, cassava materials are transformed into pellets that are easier to store, transport, and handle, while effectively reducing dust and material loss.

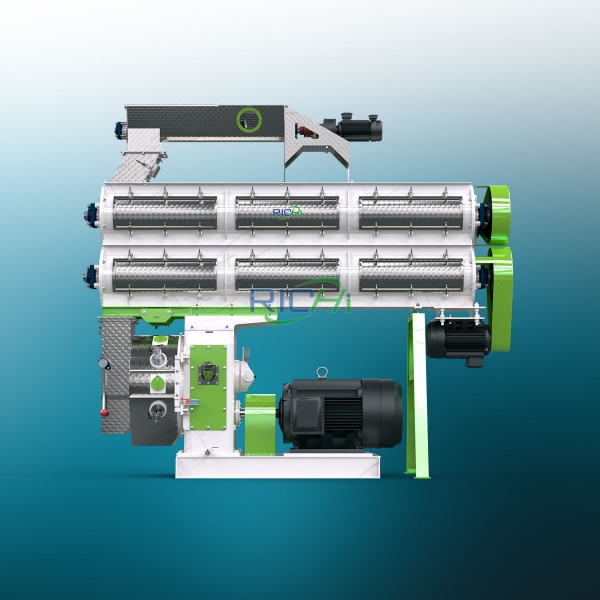

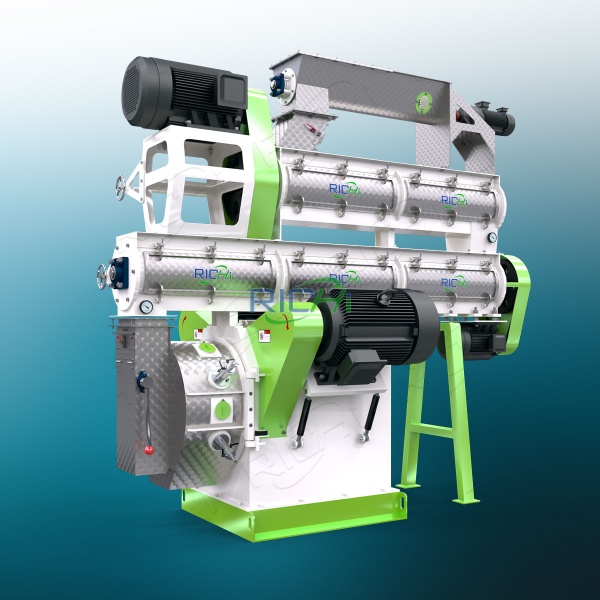

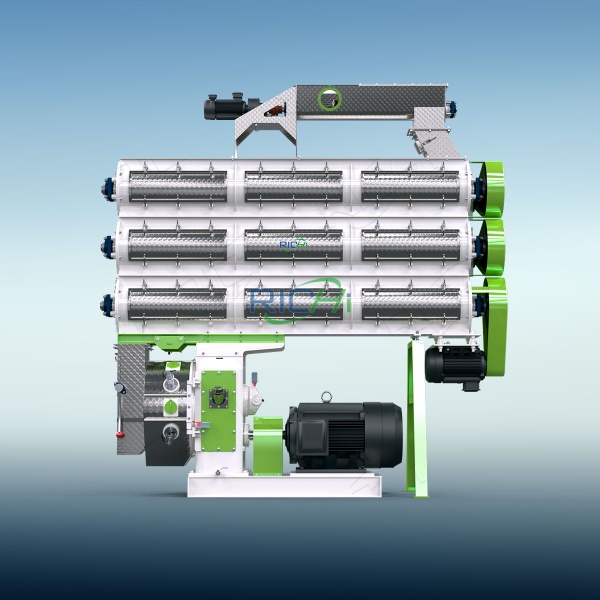

This ring die pellet machine for cassava works by applying mechanical pressure and controlled heat to conditioned materials, forcing them through precision die holes to form pellets with uniform diameter and adjustable length. The pelletizing process improves pellet density, durability, and digestion efficiency, making the final product suitable for animal feed production as well as certain plant-based litter applications.

The core pelletizing structure of the machine used for animal feed mill plant and cat litter pellets is the same. Differences mainly lie in configuration details such as motor power, die specifications, and auxiliary equipment, which are adjusted according to raw material characteristics and final pellet requirements.

As most of our customers primarily use this machine for animal feed production, the technical descriptions and configurations on this page focus on feed pellet processing. For customers planning to produce plant-based cat litter pellets, customized configurations and complete solutions can be provided upon request. Please contact us for a tailored recommendation based on your specific application.

Working Video Of Pellet Making Machine For Cassava

The following video provides a clear look at the appearance and real working condition of the cassava pellet making machine. By watching the machine in operation, you can better understand its structure, pelletizing process, and overall performance in cassava feed pellet production.

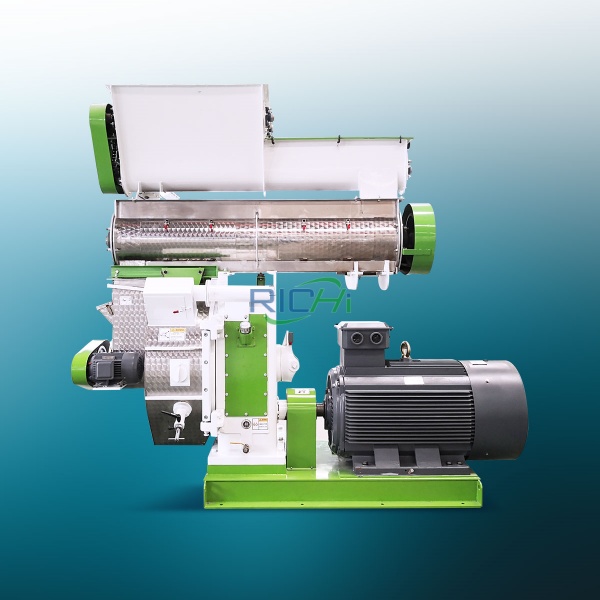

Different Models With RICHI Cassava Pellet Machine For Sale

RICHI Machinery offers different models of cassava pellet making machines to meet the production needs of cat litter production and feed mills of various scales. With flexible capacity options and reliable pelletizing performance, each model is designed to process cassava-based materials efficiently, helping customers choose the most suitable solution according to their production requirements.

SZLH250 Small Cassava Pellet Making Machine

- Main Motor Power (KW): 22

- Capacity: 1-2T/H

- Price: $7,000-10,000

SZLH320 Cassava Pellet Machine

- Main Motor Power (KW): 37

- Capacity: 3-4T/H

- Price: $10,000-20,000

SZLH350 Cassava Pellet Maker

- Main Motor Power (KW): 55

- Capacity: 5-6T/H

- Price: $25,000-32,000

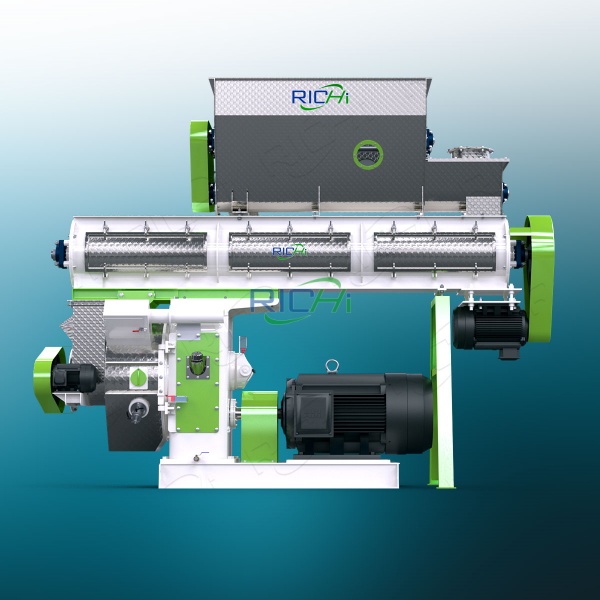

SZLH420 Cassava Pellet Mill

- Main Motor Power (KW): 110

- Capacity: 10T/H

- Price: $32,000-40,000

SZLH508 Cassava Pellet Making Machine

- Main Motor Power (KW): 160

- Capacity: 15T/H

- Price: $40,000-50,000

SZLH558 Cassava Pelletizer

- Main Motor Power (KW): 185

- Capacity: 20T/H

- Price: $50,000-60,000

SZLH678 Cassava Granulator Machine

- Main Motor Power (KW): 250

- Capacity: 30T/H

- Price: $60,000-70,000

SZLH768 Industrial Cassava Pellet Making Machine

- Main Motor Power (KW): 315

- Capacity: 401T/H

- Price: $70,000-85,000

Key Technical Characteristics Of Cassava Pellet Making Machine

The feed pellet press for cassava is engineered with stable pelletizing structure, reliable transmission system, and efficient conditioning design to ensure consistent feed pellet quality. Its technical characteristics focus on durability, efficiency, and adaptability to cassava-based feed materials, making it suitable for long-term and continuous feed production.

Global Cases Of RICHI Cassava Pellet Making Machine

With over 30 years of industry experience, RICHI Machinery has successfully delivered pellet machines and related pellet equipment products to more than 140 countries and regions. RICHI cassava pellet making machines have been successfully installed and operated in multiple countries worldwide, supporting animal feed pellet production lines of various scales. By adapting to local cassava resources and feed formulations, RICHI solutions help customers achieve stable feed pellet quality and efficient production.

Cassava Pellet Maker For Sale tanzania

- Production Capacity: 1-2T/H

- Project Country: Tanzania

- Raw Material: Cassava chips, cassava flour, mixed feed ingredients

- Project Background: Cassava is widely grown in Tanzania and is commonly used as a low-cost energy source in animal feed. The customer planned to set up a small cassava-based poultry feed pellet plant to supply nearby poultry farms while controlling initial investment costs.

- Client Feedback: “The machine runs stably and handles cassava materials very well. Pellet quality meets our expectations, and daily production is easy to manage.”

Cassava Pellet Making Machine In Poland

- Production Capacity: 2.5T/H

- Project Country: Poland

- Raw Material: Cassava flour, wood fibers, plant-based absorbents, mixed additives

- Project Background: The customer is a pet product manufacturer in Poland aiming to produce high-quality plant-based cat litter pellets using cassava as a binder and absorbent. The project focuses on uniform pellet formation, dust control, and high absorption performance for domestic cat use.

- Client Feedback: “The pellets are consistent, highly absorbent, and easy to handle. The machine runs smoothly and meets our production needs perfectly.”

Cassava Pellet Machine For Sale Peru

- Production Capacity: 6-8T/H

- Project Country: Peru

- Raw Material: Cassava chips, cassava powder, mixed feed materials

- Project Background: This project was developed for a large feed producer in Peru aiming to increase production capacity using locally sourced cassava. The animal feed processing plant was designed for continuous operation to supply feed to regional poultry and livestock farms.

- Client Feedback: “Even at high capacity, the machine operates reliably. Cassava pellets are dense and easy to store and transport.”

Cassava Pellet Mill For Sale Indonesia

- Production Capacity: 4T/H

- Project Country: Indonesia

- Raw Material: Cassava flour, cassava chips, compound feed ingredients

- Project Background: Indonesia has abundant cassava resources, and the customer aimed to produce cassava-based feed pellets for local poultry and livestock farms. The project was planned with future expansion in mind.

- Client Feedback: “The system is easy to operate, and cassava feed pellets meet our feeding requirements. The design allows us to expand capacity later.”

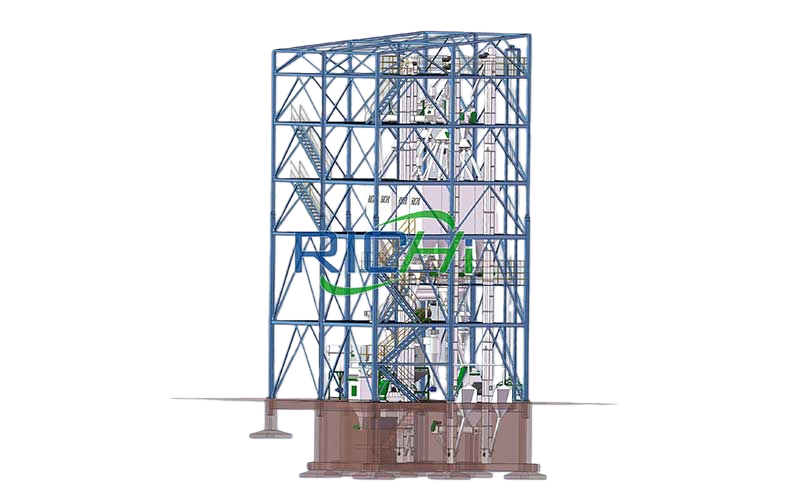

How To Produce Cassava Pellets?

Producing high-quality cassava feed pellets involves a series of coordinated steps, from raw material preparation to final pellet packaging. By following a proper production process, feed mills can ensure consistent pellet quality, improved digestibility, and reduced feed waste.

Raw Material Collection and Preparation

01

Select suitable cassava materials such as cassava chips, cassava flour, or cassava peels. Ensure the raw materials are clean, dry, and free from impurities.

Crushing Section

02

Crushing large cassava pieces into uniform particle sizes improves the efficiency of subsequent pelletizing.

Mixing Section

03

Combine cassava with protein sources, vitamins, minerals, and other feed additives according to the animal feed formula. Use a feed mixer to blend ingredients uniformly, ensuring balanced nutrition in each pellet.

Pelletizing Section

04

The mixed feed enters the cassava pellet making machine, where moisture and temperature are adjusted while pellets are formed under mechanical pressure and heat. This produces uniform, durable pellets that are easy for animals to digest. Pellet size and length can be customized for different animals.

Cooling and Screening

05

After pelletizing, the pellets are hot and soft. Use a feed cooler to reduce temperature and moisture, hardening the pellets and improving storage stability. Screen the cooled pellets to remove fines and broken pellets.

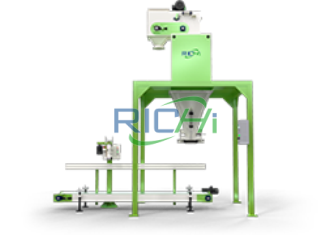

Packing Section

06

Finally, pack the finished cassava feed pellets for storage or transportation. Proper packaging ensures feed quality is maintained during delivery.

Main Cassava Pellet Equipment In The Production Line

In addition to the cassava pellet making machine, a complete feed production line includes several other essential pieces of equipment. Each component works together to ensure efficient processing, consistent pellet quality, and smooth production from raw material preparation to final packaging.

Why Choose Our Cassava Pellet Machine Equipment

RICHI cassava pellet making machines are designed for efficiency, durability, and high-quality pellet production. With advanced technology, reliable components, and user-friendly design, our machines help feed producers achieve stable production, reduce costs, and make full use of local cassava resources. Choosing RICHI means choosing a trusted solution for long-term feed pellet manufacturing.

High-Quality Equipment

Our cassava pellet making machines are built with durable components and advanced technology, ensuring stable performance and long service life. All equipment has passed multiple international certifications, guaranteeing reliability and safety in feed pellet production.

Customized Solutions

We offer tailor-made equipment and complete feed production lines to meet the specific requirements of different customers. From machine configuration to production line layout, every solution is customized to optimize efficiency, output, and cost-effectiveness.

Extensive Experience

With projects in over 140 countries and regions worldwide, RICHI has extensive experience in cassava feed pellet production. RICHI Machinery turnkey service ensures professional guidance and reliable support for clients of all scales.

FAQ

This section answers some of the most common questions about RICHI cassava pellet making machines and their applications. Here, customers can quickly find information about machine models, production capacity, customization options, and global projects, helping them make informed decisions for their feed pellet production needs.

Do I need a different machine for cat litter production?

+

No, you do not need a completely different machine. The core pelletizing structure of our cassava pellet making machine is the same for both animal feed and plant-based cat litter production. However, compared with feed production, producing cat litter pellets typically requires some additional auxiliary equipment to meet quality requirements. For example, cat litter pellets often need a lower moisture content and higher hardness, so an extra drying system may be added after pelletizing to achieve optimal moisture levels. With proper configuration, the same machine can produce high-quality, uniform cat litter pellets efficiently.

Can I produce feed pellets for different animals using cassava combined with other raw materials?

+

Yes, RICHI cassava machine equipment can handle mixed raw materials, including cassava, corn, soybean meal, and other locally available ingredients. By adjusting the formulation, pellet size, and conditioner settings, the same machine can produce pellets suitable for poultry, fish, pigs, or livestock. Different animals may require different conditioner layers or conditioning intensity to achieve optimal starch gelatinization and pellet durability. Many clients in Southeast Asia and Africa use mixed ingredients to reduce costs while maintaining high nutritional value.

How to Choose the Right Cassava Pellet Making Machine?

+

Choosing the right machine involves several factors to ensure efficient production, cost-effectiveness, and high-quality pellets:

- Technical Support & Experience: Choosing a manufacturer with global project experience ensures professional guidance in machine configuration, line layout, and operation optimization, helping maximize efficiency and investment return.

- Production Capacity: Estimate your daily feed requirement and select a machine that meets your output needs. Small-capacity machines are suitable for beginners or small feed mills, while medium-capacity machines can support larger or growing operations.

- Raw Material Flexibility: If you plan to use cassava mixed with other ingredients (corn, soybean meal, etc.), additional equipment such as a crusher, mixer, or pre-conditioning unit may be needed to ensure smooth pelletizing and consistent quality.

- Target Animal: Different animals require different pellet sizes and conditioning intensity. Poultry and fish usually need smaller pellets with lighter conditioning, while pigs or livestock may require larger pellets and additional conditioner layers for proper starch gelatinization and pellet durability.

- Customization & Expansion: RICHI provides modular design solutions, allowing clients to gradually expand production or integrate additional modules as needed. This ensures that your production line can grow with your business efficiently and cost-effectively.

By considering these factors, investors can configure the most suitable production line, ensuring smooth operation and high-quality cassava feed pellets.

I want to start small but may expand later. What is the best investment strategy?

+

For investors who want to start small and expand later, the best strategy is to begin with a basic pelletizing system and adopt a modular production line design. At the initial stage, you can invest only in the core pellet making machine with essential auxiliary equipment.

As production demand increases, additional auxiliary units—such as mixing systems, cooling machines, screening equipment, or packaging systems—can be added to the existing line. RICHI’s modular design allows capacity expansion without replacing the main pellet machine, helping reduce initial investment risk while supporting long-term growth.

I plan to produce 20 tons of cassava feed pellets per day. Which machine should I choose? How much does it cost?

+

If your target output is 20 tons per day and the plant operates 6–8 hours per day, the required pelletizing capacity would be approximately 2.5- 3.3 T/H. Based on this calculation, a cassava pellet making machine with an hourly capacity of around 3–4 tons per hour would be the most suitable choice. This capacity ensures stable production, allows for short maintenance stops, and provides flexibility for future output increases.

Regarding investment cost, the total price depends on the machine configuration and auxiliary equipment selected. The 3-4T/H feed granulator machine price ranges $10,000 to 20,000. For a production scale of 20 tons per day, the investment typically includes the pellet machine and essential auxiliary units such as mixing, cooling, and screening equipment. RICHI provides customized and modular solutions, allowing investors to control initial costs and expand the line later as production grows.