Biomass Pellet Machine Price

Biomass pellet machine prices range from $10,000 to $90,000, depending on the model, capacity, and power configuration. The RICHI MZLH series offers reliable performance and high pelletizing efficiency, making it an ideal investment for renewable energy projects of all sizes.

What is Biomass Pellet Machine?

A biomass pellet machine is a device specifically designed to compress agricultural and forestry waste (such as sawdust, wood chips, rice husks, corn stalks, straw, and bamboo chips) into solid fuel pellets. These pellets are a sustainable, clean energy source with advantages such as complete combustion, high calorific value, and low pollution, making them an ideal alternative to traditional fossil fuels such as coal and oil.

The working principle of a biomass pellet machine is simple yet highly efficient. The machine uses high temperature and high pressure to soften the lignin in the raw material. During the molding process, the lignin acts as a natural binder, resulting in compact pellets without the need for chemical adhesives. This process not only significantly reduces the volume of the raw material but also improves combustion performance, making it easier to store, transport, and use.

Generally speaking, the biomass pellet machine price ranges from $10,000 to $90,000, depending on the model, power, and capacity. Smaller models offer lower capacity and are therefore more affordable, making them suitable for small-scale production, while larger machines are more expensive for industrial-scale biomass fuel production. While the investment amount varies, choosing the right equipment ensures stable operation, high pellet quality, and long-term economic benefits.

Today, biomass pellet machines are widely used on farms, wood processing plants, biomass fuel plants, and various renewable energy projects. Depending on the model, power, and output requirements, the machine’s production capacity ranges from 0.2 tons to 4 tons per hour. Whether for home heating or industrial power generation, investing in a biomass pellet machine is an efficient and environmentally friendly option for converting waste resources into high-value energy.

Raw material

Biomass pellet machines can process a variety of agricultural and forestry wastes, such as sawdust, wood chips, rice husks, straw, bamboo chips, palm fiber, and peanut shells. However, the physical properties of different raw materials not only affect the pellet quality and yield, but also have a certain impact on the biomass pellet machine price.

When evaluating equipment price, it is important to consider the type of raw materials planned to be used. For example, production lines designed for lightweight raw materials often require customized equipment design, such as reinforced feeders, strengthened conditioners, or wear-resistant components. Choosing the right configuration not only improves pelleting efficiency but also achieves higher economic efficiency and return on investment in the long term.

Hemp

Tire fiber

Alfalfa

Logs

Corn stalk

Fruit core

Palm kernel shells

Organic waste

video of Biomass Pellet Machine

This video shows the actual test process of the RICHI biomass pellet machine, allowing you to intuitively understand its structure and operating status. By watching the actual operation of the equipment, you can more clearly understand the pelleting performance corresponding to our biomass pellet machine price.

Key structural Features of Biomass Pellet Machine

The design and structure of a biomass pellet machine largely determine its efficiency, durability, and overall performance. Every component, from the feeder, conditioner, ring die, to the main motor, directly impacts pellet quality and production costs, and these technical details are a key factor influencing the biomass pellet machine price.

A well-structured machine not only ensures a smooth and efficient pelleting process but also reduces maintenance frequency and energy consumption, resulting in a more cost-effective operation over the long term.

Sturdy Structure

The biomass pellet machine utilizes a high-strength steel structure and precision-welded construction, ensuring stable performance and an exceptionally long service life, even under high-load, continuous operation.

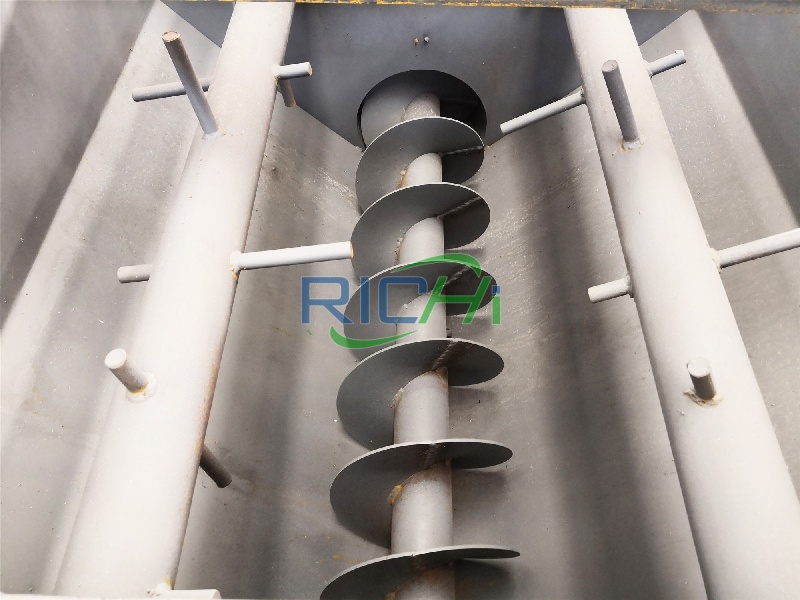

Efficient Feeding System

The machine is equipped with an adjustable-speed screw feeder for more uniform and stable raw material feeding. For lightweight raw materials such as straw and forage, an optional forced feeding system improves pelleting efficiency.

Precision Roller Assembly

The rollers and ring die are constructed of wear-resistant alloy steel, providing high compression strength and uniform pellet density, ensuring pellet quality and extending equipment life.

High-Precision Ring Die

The ring die is constructed of high-quality stainless steel and offers a variety of apertures to meet varying pellet diameter requirements. High-precision drilling ensures smooth discharge and stable output.

Intelligent Electrical Control System

The electrical control cabinet integrates automatic protection, overload detection, and real-time monitoring functions, ensuring safe and convenient operation. The variable frequency control design allows for flexible speed adjustment based on production needs.

High-efficiency motor drive

Equipped with a highly efficient and energy-saving Siemens motor, the machine delivers stable torque and powerful power, ensuring continuous, efficient pelletizing and reducing energy consumption.

After understanding the key structural features of biomass pellet machines, we can see that these structural design details directly determine the overall performance and production efficiency of the equipment. A more powerful main motor, upgraded reducer, or improved feeding system can all improve pelleting capacity. These structural differences not only explain the performance differences between different models, but are also the key reason for the difference in biomass pellet machine price.

different Technical Parameters with different Biomass Pellet Machine Price

The biomass pellet machine price varies depending on the equipment’s technical specifications, including motor power, production capacity, and die size. Generally speaking, models with higher power and capacity are more expensive. These models are suitable for continuous industrial production and can handle hard or high-density materials.

Each model in our MZLH series is optimized for different needs. Understanding the differences in these technical parameters can help users achieve the optimal balance between investment and production capacity. Below are detailed technical specifications and corresponding price ranges for each model to help you more clearly select the most suitable equipment.

MZLH320 Biomass Pellet Machine

- Main Motor Power (kW): 22

- Broken Arch Feeder Power (kW): 2.2

- Forced Feeder Power (kW): 0.75

- Ring Die Inner Diameter (mm): 320

- Output (T/H): 0.2-0.3

- Biomass Pellet Machine Price: $10,000-$20,000

MZLH350 Biomass Pellet Mill

- Main Motor Power (kW): 37

- Broken Arch Feeder Power (kW): 2.2

- Forced Feeder Power (kW): 0.75

- Ring Die Inner Diameter (mm): 350

- Output (T/H): 0.3-0.5

- Biomass Pellet Mill Price: $20,000-$25,000

MZLH420 Biomass Pellet Machine

- Main Motor Power (kW): 90

- Broken Arch Feeder Power (kW): 3

- Forced Feeder Power (kW): 1.5

- Ring Die Inner Diameter (mm): 420

- Output (T/H): 1-1.2

- Biomass Pellet Machine Price: $25,000-$35,000

MZLH520 Biomass Pellet Making Machine

- Main Motor Power (kW): 132

- Broken Arch Feeder Power (kW): 3

- Forced Feeder Power (kW): 1.5

- Ring Die Inner Diameter (mm): 520

- Output (T/H): 1.5-2

- Biomass Pellet Making Machine Price: $40,000-$50,000

MZLH678 Biomass Pellet Machine

- Main Motor Power (kW): 200

- Broken Arch Feeder Power (kW): 3

- Forced Feeder Power (kW): 1.5

- Ring Die Inner Diameter (mm): 673

- Output (T/H): 2.5-3

- Biomass Pellet Machine Price: $60,000-$70,000

MZLH768 Biomass Pellet Machine

- Main Motor Power (kW): 315

- Broken Arch Feeder Power (kW): 4

- Forced Feeder Power (kW): 1.5

- Ring Die Inner Diameter (mm): 762

- Output (T/H): 3-4

- Biomass Pellet Machine Price: $80,000-$90,000

Different Project Cases of Different Biomass Pellet Machine Price

RICHI Machinery has successfully designed various types of biomass pellet machines in numerous countries and regions. Each project is tailored to the client’s feedstock type, production requirements, and local conditions. From small production lines to large commercial plants, RICHI provides comprehensive solutions encompassing process design, equipment manufacturing, installation guidance, and personnel training. These real-world cases fully demonstrate RICHI’s extensive experience, advanced technology, and commitment to sustainable development.

RICHI Machinery has over 30 years of experience in equipment manufacturing, with projects spanning over 140 countries and regions worldwide. And we can provide customized pellet equipment products and pellet plant solution tailored to your specific needs, achieving the best cost-performance ratio, ensuring stable operation, and delivering a high return on investment.

MZLH678 Biomass Pellet Machine For Sale Mauritius

- Project country: Mauritius

- Project output: 2-3T/H

- Raw materials: Paper and paper waste

- Biomass pellet making machine price: About $65,000

- Biomass pellet plant price: About $78,000

- Project background: Mauritius is actively promoting renewable energy and sustainable waste management. Paper waste recycling is becoming increasingly important, reducing landfill pressure and generating clean energy. A customer invested in a 2-3 ton/hour biomass pellet production line. Using our pelletizer, they efficiently convert various paper waste types into high-quality pellets, saving energy costs and contributing to local sustainable development goals.

MZLH768 Biomass Pellet Machine For Sale Poland

- Project country: Poland

- Project output: 3T/H

- Raw materials: Scrap tires, rubber waste, old conveyor belts

- Biomass pellet machine price: About $80,000

- Biomass pellet manufacturing plant price: About $82,000

- Project background: Poland is facing increasing pressure to sustainably process scrap tires and industrial rubber waste. Converting these materials into biomass pellets not only offers a renewable fuel alternative but also reduces environmental pollution. By investing in our equipment, customers can effectively process rubber waste and produce uniform pellets, providing a stable fuel source for local energy applications.

MZLH520 Biomass Pellet Machine For Sale Indonesia

- Project country: Indonesia

- Project output: 2T/H

- Raw materials: Wood logs, sawdust, wood shavings, wood residues

- Biomass pellet machine price: About $45,000

- Biomass pellet making plant price: About $60,000

- Project background: Indonesia has abundant timber resources and a growing demand for renewable energy. Converting wood residue into wood pellets can meet energy needs while reducing waste. Our biomass pellet machines are simple and efficient to operate. By investing in our equipment, customers can fully utilize wood residue, efficiently produce environmentally friendly pellets, and reduce operating costs.

MZLH520 Biomass Pellet Machine For Sale Romania

- Project country: Romania

- Project output: 1.5T/H

- Raw materials: Agricultural residues (corn stalks, rice husks), forestry residues, grass, straw

- Biomass pellet machine price: About $43,000

- Complete biomass pellet making machine price: About $58,000

- Project background: Romania is promoting rural renewable energy projects to utilize abundant agricultural and forestry residues. Producing biomass pellets helps reduce fossil fuel consumption and support local economic development. Our versatile equipment processes a variety of biomass materials into high-quality pellets, ensuring stable yields and supporting local sustainable energy development.

Why Choose RICHI Biomass Pellet Machine?

Choosing the right equipment requires considering not only the biomass pellet machine price, but also the quality, stability and long-term return on investment. RICHI Machinery has over 30 years of experience manufacturing biomass pellet equipment, integrating advanced design, durable materials, and intelligent control systems. Each model is precisely engineered to achieve high output while minimizing energy consumption, offering customers the optimal balance between performance and cost.

While biomass pellet machine price is a primary consideration when purchasing, the true determinant of return on investment lies in the machine’s performance stability, energy consumption, and after-sales service. Low-priced equipment may save initial budget, but in the long run, high maintenance costs, low production output, or frequent downtime often increase overall expenses. RICHI’s biomass pellet machines offer superior pelleting performance, a rugged design, and a comprehensive global service system within a reasonable price range. The price of each piece of equipment reflects the comprehensive value of its performance, quality, and service. Choosing RICHI means choosing higher production capacity, lower energy consumption, and longer-term operational profitability.

FAQ

When deciding to invest, customers are most concerned not only about the biomass pellet machine price, but also about equipment performance, raw material compatibility, and how to choose the most suitable equipment based on their budget. To help you more clearly understand the overall value of RICHI biomass pellet machines, we have compiled frequently asked questions and professional answers to help you make a more informed investment decision.

What is the biomass pellet machine price?

+

Biomass pellet mill prices range from $10,000 to $90,000, depending on factors such as production capacity, feedstock type, machine model, and the degree of automation and auxiliary equipment. Small-scale equipment is relatively inexpensive, while large-scale industrial pellet plants use more sophisticated equipment, requiring a higher investment.

When investing, choosing high-quality equipment ensures high efficiency, consistent pellet quality, and long-term operational cost savings. Therefore, customers shouldn’t focus solely on the purchase price; a reliable machine can reduce maintenance costs, energy consumption, and downtime over time, ultimately providing greater value in the long run.

How do I choose the most suitable biomass pellet machine according to my budget?

+

Choosing the right biomass pellet machine for your budget requires balancing capacity requirements, equipment configuration, and feedstock type.

- First, determine your production requirements. Smaller models tend to be more affordable, while larger models designed for industrial production lines are more expensive.

- Next, consider the equipment configuration. Some models often offer automation, energy efficiency, and low maintenance, while simpler models are less expensive but may require more manual operation. In addition to the purchase price, consider long-term operating costs, including electricity, maintenance, and spare parts.

- Also, consider the feedstock type. Lightweight feedstocks like straw and stalks may require a force feeder, and these additional features will also affect the biomass pellet machine price.

Working with a reliable supplier ensures that the equipment you choose meets your budget, production goals, and delivers consistent pellet quality and reliable performance.

Can a biomass pellet machine deal with different raw material?

+

Yes, the RICHI biomass pellet machine can process a variety of biomass feedstocks, including wood logs, sawdust, wood chips, agricultural residues (corn stalks, rice husks, straw), paper waste, and even industrial waste such as rubber or cardboard. The key is selecting the appropriate machine model and die configuration based on the feedstock type and moisture content.

For some light or fluffy feedstocks, such as straw or certain types of paper, an additional force feeder may be required to ensure stable feeding and consistent pellet quality.

Using a properly configured, versatile machine allows customers to switch between different feedstocks without compromising pellet quality. This flexibility helps maximize resource utilization, minimize waste, and expand commercial opportunities for renewable fuel production.

If I need a biomass pellet machine with a capacity of 2-3T/H, what is its price?

+

The biomass pellet machine price with a production capacity of 2.5-3 tons/hour is generally between US$60,000 and US$70,000, depending on the feedstock type, machine model, degree of automation, and whether additional equipment such as dryers, hammer mills, and conveying equipment is required.

Investing in high-quality equipment ensures stable pellet production and consistent quality, and improves long-term operational efficiency. While the initial purchase price is important, customers should also consider long-term benefits such as reduced maintenance costs, reduced labor input, and energy savings.