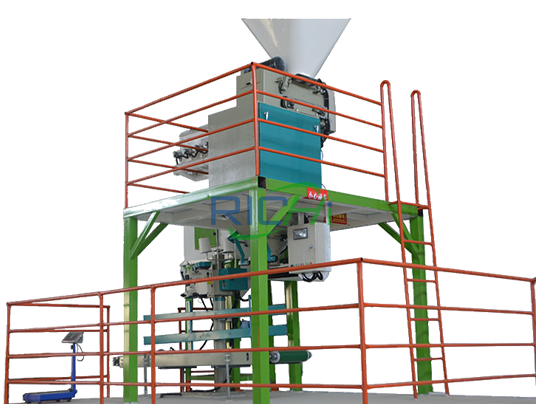

animal feed bagging machine

Animal feed bagging machine is indispensable equipment in modern feed mill, capable of processing pellet feed and powdered feed with high precision. It ensures consistent weight and neat seals, facilitating subsequent storage and transportation, and delivering high-quality, professionally packaged products to the market.

RICHI MACHINERY

product introduction Of animal feed bagging machine

The animal feed bagging machine is a specialized piece of equipment primarily used to weigh feed into bags weighing 10 to 50 kg. Sealing methods include thermoplastic sealing, seam sealing, and mixed sealing. Equipped with advanced load cells, a PLC control system, and an automatic sealing mechanism, it ensures efficient and accurate packaging.

Compared to traditional manual packaging, the automated bagging system significantly reduces labor intensity, reduces human error, and significantly improves efficiency. Furthermore, its shock-resistant design, advanced load cells, and intelligent fault detection system not only enhance accuracy and stability, but also extend the equipment’s lifespan, making it an ideal long-term investment for feed manufacturers.

This machine can process both powdered and pelleted feed. It is widely used not only in animal feed pellet mill but also in various other industries requiring precise weighing and packaging of bulk materials.

RICHI MACHINERY

Working Principle of feed bagging equipment

To better understand the value of an animal feed bagging machine, we need to gain a deeper understanding of its operation. After briefly introducing the product, we’ll now delve into its working principle to more intuitively demonstrate its efficiency and reliability in practical applications.

The operation generally involves five main steps:

- Feeding: The material is automatically fed into the equipment through the feeding device. The feeding speed can be adjusted according to the characteristics of different materials.

- Weighing: Materials enter the high-precision weighing system and are detected by advanced sensors. Anti-vibration devices effectively reduce vibration interference, ensuring static accuracy ≤ ±0.1% and dynamic accuracy ≤ ±0.2%.

- Bagging: When the weighing reaches the set value, the material is automatically discharged into the pre-positioned packaging bag. The rational design of the bagging system can reduce dust and material spillage, ensuring a clean and efficient process.

- Sealing: After bagging, the bags are conveyed to the sealing unit via a conveyor. Depending on your needs, you can choose to use heat sealing, seam sealing, or a combination of sealing methods to ensure a durable and secure package.

- Outfeed and Conveying: Finished bags are conveyed to the discharge area, where they can be stacked manually or automatically. PLC microcomputer control ensures stable operation and includes fault detection and parameter adjustment capabilities.

The animal feed bagging machine is more than just a piece of advanced equipment; it’s a complete modern packaging solution. Its workflow ensures precision and efficiency at every stage. By rigorously controlling each step, the equipment ensures accurate weighing data, consistent packaging quality, and a stable, smooth production process, avoiding unnecessary downtime and waste.

It is this highly coordinated process that transforms raw materials into standardized, market-ready finished products. From reducing raw material waste to improving labor efficiency, this equipment effectively enhances overall production efficiency and product value.

Key Advantages of the feed bagging machine

— Richi Machinery —

When choosing an animal feed bagging machine, companies often prioritize accuracy, efficiency, and stability. Compared to traditional manual packaging, this equipment offers a range of unique advantages that significantly improve production efficiency and reduce operating costs. The following is a detailed description of its key advantages:

Anti-Shock System Ensuring Accuracy and Speed

The equipment features a unique anti-shock system design that minimizes vibration interference during operation. This feature is particularly important in feed mills, where multiple large pieces of equipment often operate simultaneously. By reducing external influences, the anti-shock system ensures accurate and stable weighing, enabling fast and precise packaging.

Flexible Packaging Range with Easy Adjustment

The packaging range of the equipment ranges from 10–50 kg per bag, freely adjustable to meet production needs. This makes it suitable for both small-scale farms and large-scale industrial production lines. Whether it’s powdered or pelleted feed, the system can adapt flexibly, eliminating the need for frequent manual calibration.

High Weighing Precision and Fine Resolution

This animal feed bagging equipment offers excellent weighing performance: static error ≤ ±0.1% and dynamic error ≤ ±0.2%. Furthermore, its display resolution of up to 10 grams allows operators to clearly monitor even minute weight variations. This high accuracy not only improves the quality of the finished product but also effectively prevents raw material waste.

Smart Control with Automatic Fault Detection

The microcomputer and PLC system not only performs routine operations but also features intelligent fault detection. If an abnormality occurs, the system immediately issues an alarm, minimizing downtime and improving reliability. This intelligent feature ensures continued efficient operation in high-intensity production environments.

Seamless Integration of Mechanical Structure and PLC Control

This packaging system combines mechanical components (feeding unit, weighing scale, sensors, conveyor, sealing device, and pneumatic components) with a PLC microcomputer intelligent control unit. This structural design ensures smooth operation while facilitating parameter adjustment and real-time monitoring. This dual-system design minimizes manual intervention while maintaining stability and flexibility.

Cost Efficiency and Long-Term Investment Value

By replacing manual labor with automation, this animal feed bagging machine significantly reduces labor costs, minimizes human error, and improves production efficiency. Furthermore, its rugged design and components ensure a long lifespan, making it a reliable, long-term investment for manufacturers.

Overall, this equipment combines precision, efficiency, flexibility, and reliability. With its optimized operational processes and integrated technical design, it is an ideal tool not only for modern feed mills but also for other industries requiring bulk material packaging. These advantages ultimately translate into higher product quality, lower operating costs, and greater market competitiveness.

RICHI MACHINERY

Specifications & Parameters

of animal feed bagging machine

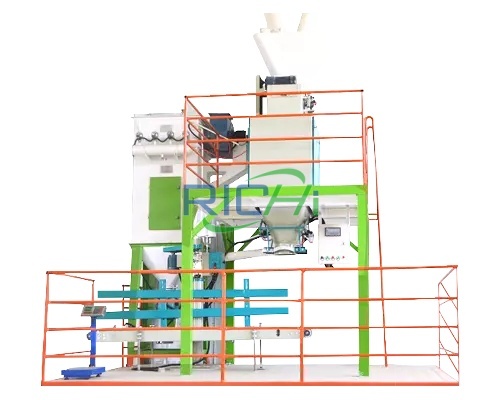

The performance of a machine depends on its structure and configuration. The RICHI DCS series of fully automatic packaging scales are designed specifically for the high-precision, high-efficiency packaging needs of industries such as feed pellets, wood pellets, and biomass pellets. RICHI offers a variety of machine specifications and models to meet the needs of different production volumes and application scenarios.

| Model | DCS-50W | DCS-50K | DCS-50F | DCS-50P | DCS-50P*2 | DCS-50FB(stainless steel) |

| Application | Pellets | Pellets | Powder | Pellets, Powder | Pellets, Powder | Premix |

| Feeding Method | Gravity Feeding | Gravity Feeding | Screw Feeding | Belt Feeding | Belt Feeding | Screw Feeding |

| Packing Speed (bags/min) | 2~3 | 5~6 | 6~8 | 6~8 | 10~12 | 6~8 |

| Power(kw) | 0.55+0.37 | 0.55+0.37 | 1.5+0.55+0.37 | 1.5+0.55+0.37 | 1.5*2+0.55+0.37 | 1.5+0.55+0.37 |

| Packing Accuracy | Static±0.1% Dynamic±0.2% | Static±0.1% Dynamic±0.2% | Static±0.1% Dynamic±0.2% | Static±0.1% Dynamic±0.2% | Static±0.1% Dynamic±0.2% | Static±0.1% Dynamic±0.2% |

| Air Supply Requirement | 0.4-0.6MPa 1.5m3/h | |||||

In summary, RICHI’s various feed packing machines and specifications fully meet the production needs of feed pellet production lines. Their stability and reliability help companies reduce labor costs and improve production efficiency. Choosing RICHI means choosing a guarantee of efficiency, safety, and long-term value. If you have any questions about the equipment, including questions about how to choose the right model, please feel free to contact us.

How animal feed bagging machine be applied in feed Pellet Production Line?

In modern pellet production lines, every piece of pellet equipment plays a vital role in ensuring smooth production and product quality. Among them, the feed bagging system is one of the indispensable links. Taking this 5-7 ton/hour animal feed pellet production line as an example, each piece of equipment operates in a coordinated process, from raw material receiving, crushing, and mixing to pelleting, cooling, and packaging. The entire process is seamlessly linked and the feed bagging machine represents the final stage in a feed production line:

- Receiving Section: After receiving, the raw materials undergo cleaning and preliminary processing before entering the crushing stage.

- Crushing Section: Hammer mills pulverize the raw materials into a fine powder to ensure optimal pelleting.

- Mixing Section: The various raw materials are evenly blended in a blender, and nutrient premixes may be added to ensure nutritional balance in each pellet.

- Pelleting Section: The feed granulator machine presses the mixed powder into dense, uniform pellets.

- Cooling Section: The feed pellet cooler uses countercurrent cooling to keep pellet temperature close to room temperature and reduce moisture to a safe level.

- Packaging Section: The cooled pellets are screened to remove fines, then weighed and packaged for transportation and sale.

Throughout the entire production line, the animal feed bagging machine is not only the final step in product completion but also a crucial element in ensuring the standardized and efficient distribution of finished products. It not only connects the upstream and downstream processes of the production line but also directly determines the market competitiveness and customer satisfaction of the final product.

Frequently Asked Questions

To help customers better understand the performance and benefits of animal feed bagging machines, we’ve compiled some frequently asked questions. Whether you’re new to automated packaging or considering upgrading your existing system, the answers below will provide clear guidance and help you make a more informed decision.

What types of raw material can be bagged?

Our animal feed bagging equipment is primarily designed for packaging granular and powdered materials, and is particularly suitable for feed pellet production lines of varying sizes. To ensure product quality, storage safety, and smooth distribution, the bagging process in the production line demands extremely high weighing accuracy, packaging consistency, and seal reliability.

This system is also suitable for wood pellet and biomass pellet production lines, as well as for packaging grain, fertilizer, chemical powders, plastic pellets, and other materials. With an adjustable bagging range of 10–50 kg, shock-resistant weighing technology, and a PLC intelligent control system, the machine maintains stable operation and efficient metering regardless of the material being processed.

In short, if your core needs are the production and packaging of feed pellets, wood pellets, or biomass pellets, our automated bagging system is the most reliable and cost-effective solution.

What bag sizes are supported?

Our DCS series of fully automatic packaging machines supports a wide range of bag sizes, typically 10–50 kg/bag, meeting the standard requirements of feed pellet production lines and most other applications. The machine’s adjustable design allows operators to easily adjust bag weights to meet production requirements without lengthy downtime or complex calibration.

This flexibility allows the machine to adapt to different bag sizes, ensuring compatibility with various storage, transportation, and market requirements. The intelligent PLC control system maintains consistent packaging accuracy even when switching between different bag weights or material types, ensuring efficiency, precision, and minimal material waste.

In short, whether you need small packages for retail or large packages for bulk shipping, our systems provide a reliable and versatile solution for your production.

Can it be integrated into existing lines?

Yes, our animal feed bagging machine features a modular and flexible design that can be seamlessly integrated into existing feed pellet production lines. Whether your production line includes crushing, mixing, or pelleting, the bagging machine can be customized to achieve continuous and efficient production. The complete animal feed making machine price ranges from 10,000-2,800,000 USD

The equipment is also adaptable to other applications, such as wood pellets or biomass pellets. Its PLC intelligent control system and adjustable interfaces enable automatic linkage with upstream and downstream equipment, reducing manual operations, minimizing errors, and improving overall production line efficiency.

In short, integrating the DCS series bagging system into an existing feed pellet production line enables high-precision, reliable, and high-speed packaging operations, improving production efficiency and delivering long-term operational value.

how to choose the right model?

Choosing the right model depends primarily on the production requirements of your feed pellet production line, including capacity, bag specifications, and material properties.

- Production Capacity: Evaluate your hourly or daily production volume. Machine models range from small-scale operations to large-scale industrial production. Choosing the right model ensures smooth, bottleneck-free production.

- Bag Size: Consider common bag weights in the market. Our machines support bag sizes of 10–50 kg, with adjustable settings based on your needs.

- Material Type: While primarily designed for feed pellets, we can also handle other granular or powdered materials, and we offer customized solutions for lightweight or slightly sticky materials.

- Integration Requirements: If you plan to integrate the machine into an existing feed pellet production line, choose a model with appropriate interfaces and PLC control for seamless integration.

In short, the key to choosing the right machine is matching the machine’s capacity, flexibility, and automation features to your production goals. Our sales and technical teams can provide customized recommendations to help you achieve efficient production and ensure a long-term return on your investment.

RICHI MACHINERY

WHY CHOOSE US?

Selecting the right equipment suppliers is key to achieving stable production and long-term profitability. As an industry-leading manufacturer, RICHI MACHINERY combines decades of experience, advanced technology, and a global service network to deliver equipment that meets customer needs and customizes production lines. The following three core advantages will demonstrate why thousands of global clients choose to partner with us.

Strict quality standards and rich experience

With over 20 years of experience in animal feed bagging machine manufacturing, we have served thousands of customers worldwide across more than 120 countries and regions.

Our reputation stems from strict international quality standards, with all products certified by ISO, CE, SGS and other international certifications, ensuring stable performance and reliable quality.

Customized animal feed bagging scheme

We customize pellet bagging solutions for each customer, with advanced technology and professional design services, covering the whole process support from manufacturing, delivery to installation and training.

Each solution aims to help customers achieve efficient, intelligent and sustainable production.

Comprehensive after-sales service guarantees long-term operation

Our commitment extends beyond equipment supply to include rapid response after-sales services covering everything from initial consultation to long-term maintenance.

We are dedicated to building lasting partnerships rooted in responsibility and trust. Contact us now for customized solutions and quotations that will elevate your production to new heights.