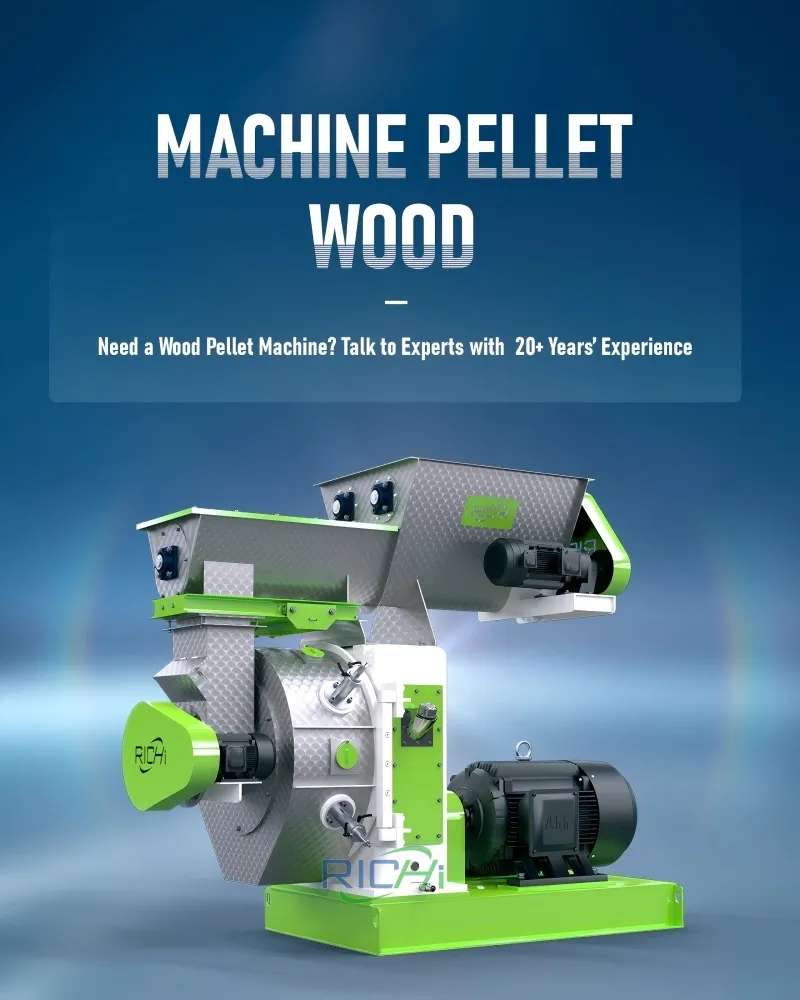

wood pellet press machine

Designed with innovation and built for durability, our wood pellet press machine is ideal for a wide range of users. Unlike traditional fuel sources, the production which produced by our machine are cleaner, easier to store and more environmentally friendly.

Introduction of RICHI wood pellet press machine

A wood pellet press machine, also known as a biomass pellet mill, is a specialized device used to compress finely ground biomass materials into small, dense cylindrical pellets. These pellets serve as an eco-friendly, renewable fuel source that is increasingly used in residential heating systems, industrial boilers, and biomass power plants. Thanks to their high combustion efficiency, low emissions and ease of storage and transportation, wood pellets are becoming a popular alternative to fossil fuels worldwide.

The RICHI wood pellet press machine builds on this foundational technology with advanced engineering and optimized performance. Our wood pellet press can process a wide range of raw materials, such as sawdust, straw, rice husks, palm fiber, and peanut shells. It delivers consistent pellet quality with high output efficiency. Operating on the principle of high-pressure compression and natural lignin bonding, our machine produces pellets with uniform size, high density and excellent burning properties.

Looking for a way to cut fuel costs, reduce carbon emissions or build a more sustainable business? Check us out. We RICHI, offers a practical and efficient answer.

RICHI MACHINERY

How the wood pellet press machine Works

The RICHI wood pellet press transforms powdered raw materials into dense, uniform pellets through a high-pressure compression process.

Firstly, raw materials are crushed and dried to an ideal moisture content of 12%–15%. Once prepared, they are fed into the pelletizing chamber via a screw feeder. By doing this, it will ensures a steady and consistent material flow. Inside the chamber, a set of heavy-duty rollers press the material against a rotating ring die with uniformly distributed holes.

As pressure and heat build up, the natural lignin in the biomass softens and acts as a binder. It allows the material to fuse without any added chemicals. The compressed biomass then extruded through the die holes, forming cylindrical pellets. A cutting knife trims them to the desired length. After that, they will be discharged and cooled.

RICHI MACHINE

Core Components & Performance Features

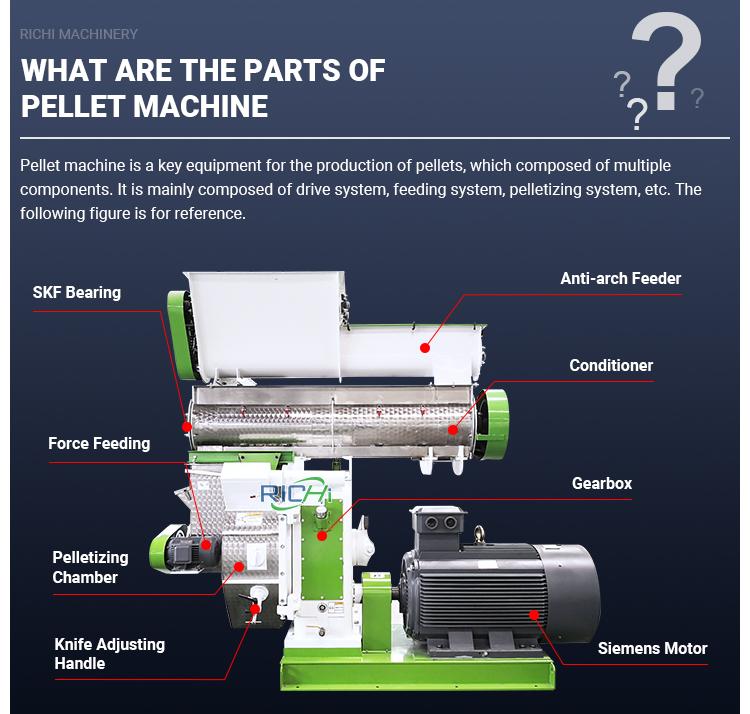

RICHI wood pellet press machine is built with precision components that work together to ensure optimal pelletizing performance. Each part is carefully selected for durability, efficiency, and ease of maintenance. The key components include:

RICHI MACHINERY

Wood Pellet Machine in Action: Introduction, Testing & Output

The following videos demonstrate the functionality, performance, and finished output of our wood pellet machine. All footage is recording at RICHI Machinery or client test sites. These videos are for reference only and may reflect customized configurations. You can find more information on our youtube channel.

Biomass Wood Pellet Machine Introduction

Wood Pellet Press Machine Trial Run Testing

How Wood Pellet Machines Work

RICHI MACHINERY

Advantages & Benefits of wood pellet press machine

The RICHI wood pellet press stands out in the biomass processing industry due to our well-rounded design and practical performance. It not only delivers stable pelletizing results but also provides economic and operational advantages for both small-scale and industrial users. Here are some of its most notable benefits:

Cost Efficiency

Able to process low-cost agricultural and forestry residues into high-value pellets.

High Pellet Quality

Uniform shape, high density and good durability make pellets easier to transport and store.

User-Friendly Design

Simple structure and intuitive control panel make it easy to operate and maintain.

Versatile Raw Material Compatibility

Works with sawdust, straw, rice husks, peanut shells and more.

Strong Durability

Built with high-quality alloy steel and precision machining, ensuring long service life.

These advantages of our wood pellet press machine help customers achieve reliable and long-term pellet production with lower operational cost.

Applications of RICHI wood pellet press machine

The RICHI wood pellet press is suitable for a wide range of biomass applications, making it a practical investment for various industries. Whether for personal use or industrial purposes. Our machine can turn raw biomass into valuable energy or functional products. Common application scenarios are as follow:

Biomass Fuel Production

Usually, we configure the poultry feed pellet plant processing ideal for making pellets that can be used in stoves, boilers, and biomass power plants.

Agricultural Waste Recycling

Converts crop residues into fuel pellets, reducing environmental waste.

Wood Processing Waste Utilization

Processes sawdust, wood chips, and shavings into commercial heating pellets.

Animal Bedding Pellets

Produces soft, absorbent pellets suitable for livestock bedding.

Pellet Export Business

Helps entrepreneurs manufacture high-quality pellets for international markets.

Whether for on-site energy use, commercial distribution or environmental waste reduction, the RICHI wood pellet press machine offers reliable performance across all application sectors.

Customer Feedback

Over the years, RICHI wood pellet press have been successfully deployed in over 120 countries and regions. Customers from Southeast Asia, Europe, Africa, and South America have consistently praised the machine for its durability and high-quality. Feedback from customers across these markets has been overwhelmingly positive. Here are some examples:

● wood

wood pellet production line in Australia

We installed our biomass pellet production line in Australia, and after more than a year of operation at the customer’s biomass heating plant, they reported that the machine required minimal maintenance. Moreover, they noted that the pellet quality remained consistently high, even as the raw materials changed with the seasons.

● sawdust

2 tons sawdust wood pellet press machine in Singapore production line

Another customer in Southeast Asia reported a 20% boost in operational efficiency after replacing their older wood pellet machine with a RICHI unit.

● biomass

biomass processing company in Indonesia

For instance, a biomass processing company in Southeast Asia reported a 25% improvement in production efficiency and a 40% reduction in downtime after switching to RICHI pellet machines.

● grass

wood pellet press machine sale for Poland

Another customer in central Europe. praised the wood pellet press adaptability, noting that it processed both bamboo chips and palm fiber without issue. There equipment couldn’t manage before but RICHI helps to handled this problem successfully.

RICHI MACHINERY

Parameters of RICHI wood pellet press machine

We offers a menu of wood pellet machines so you get what you want! It’s a solutions-based approach to feed pelletizer design and manufacturing. Instead of forcing customers to make a choice on one model, you get 5 options from a single manufacturer:

| Model | MZLH320 | MZLH320 | MZLH420 | MZLH520 | MZLH768 |

| Output (t/h) | 1-2T\H | 3-4T\H | 8-12T\H | 10-18T\H | 20-30T\H |

| Main motor power (kw) | 22KW | 37KW | 110KW | 160KW | 220-250KW |

| Main motor series | 4p | ||||

| Ring die diameter (mm) | 320 | 420 | 520 | 768 | 852 |

| Finished pellet diameter (mm) | 6-12 | ||||

| Additional | Feeder Auger Speed: 10-120 RPM Pellet size:4,6,8,10mm, etc. Roller Number: 2 or 4 Noise:≤80dB(A) Die Working Temperature: ≤85℃ | ||||

If you need help to choose the right animal feed pellet press, please contact us and tell us your daily output needs, we’ll recommend the best type match to you.

Integration into a Complete Wood Pellet Mill Plant

The RICHI wood pellet press machine is more than just a standalone unit—it’s specifically designed to function as part of a complete wood pellet production line. In larger-scale operations, it typically works in conjunction with hammer mills for grinding raw materials, rotary dryers for controlling moisture levels, and pellet coolers for stabilizing pellet temperature after processing.

Once the pelletization process is complete, the pellets can then be automatically bagged using a packing machine. By integrating the pellet press into a fully connected production system, businesses can benefit from a streamlined and continuous workflow—from raw material preparation all the way to final product packaging.

To support this, RICHI offers comprehensive engineering services and works closely with clients to develop customized biomass pellet production lines tailored to their available space, required capacity, and budget.

For a fully customized solution, you’re welcome to contact us directly.

About us

RICHI MACHINERY

The RICHI wood pellet press machine is more than just a piece of equipment, it is a complete solution for biomass resource conversion. With high efficiency, strong adaptability, and consistent performance, our machine has earned a reputation as a top-tier pelletizing solution worldwide.

Whether you are entering the biofuel business, looking to upgrade your existing system, or simply seeking a reliable machine for your heating needs, RICHI provides the quality and support necessary to succeed in the biomass fuel industry.

From its precision-engineered components to its seamless integration into large-scale lines, this machine is built to deliver efficiently, sustainably, and reliable results.

Frequently Asked Questions

Customized solutions can help different customers meet their unique business needs, improve efficiency, and reduce costs.

What kind of raw materials can the RICHI wood pellet press machine handle?

Our wood pellet press is highly versatile and can process a wide range of biomass materials including sawdust, wood chips, rice husks, straw, peanut shells, palm fiber, bamboo, and even some agricultural residues. As long as the materials are properly crushed and dried, the machine can compress them into high-quality pellets.

What’s the difference between flat die and ring die pellet machines?

Which one should I choose?

Flat die machines are ideal for small-scale or household use because they’re compact, affordable, and easy to maintain. Ring die machines are designed for industrial or commercial production with higher output, better compression, and longer working hours. The choice depends on your production scale and budget.

Do I need to dry the raw materials before pelletizing?

Yes. For best results, the moisture content of the raw material should be between 10% and 15%. If it’s too wet or too dry, it will effect the pellet quality. So you can add a drying machine to you production line.

What kind of power options does the machine support?

RICHI wood pellet press machines are available in multiple power configurations, including electric motor, diesel engine, and PTO-driven versions. We will recommend the most suitable one based on your local energy availability and usage conditions.

How long do the die and roller last? Are they easy to replace?

With proper operation and maintenance, the die and roller can last for several hundred hours of production. The exact lifespan depends on the raw material type and usage frequency. Replacing them is straightforward and we provide easy-to-follow guides for our customers.

How to maintain the machine? Are they easy to protect and maintain?

Despite its advanced features, the RICHI wood pellet press press for sale is designed with easy maintenance in mind. While the machine is designed for reliability, following a basic care routine can greatly extend its lifespan and reduce repair costs. Key maintenance practices include:

- Lubrication: Apply proper lubricants to the bearings and rotating parts regularly to reduce wear.

- Die & Roller Cleaning: Clean die holes after every session to prevent material build-up and clogging.

- Gearbox Inspection: Check oil levels and watch for unusual noise or overheating during operation.

- Belt Tension Check: Adjust drive belts periodically to maintain power transmission efficiency.

- Tighten Loose Bolts: Inspect and secure all fasteners to ensure machine stability.

- Spare Part Readiness: Keep extra dies, rollers, and grease on hand for quick replacements when needed.

Following these simple steps will help you keep the machine running smoothly and maximize production output.

Can the machine be part of a complete pellet production line?

Absolutely. RICHI offers complete pellet plant solutions. The wood pellet press machine can be seamlessly integrated with a hammer mill, dryer, cooler, screener, and packing system to form a full-scale production line.

Do you offer installation and training services?

Yes, we offer installation guides, online video support, and overseas technical assistance. We’re committed to helping every customer get started smoothly.

Can I customize the machine according to my needs?

Yes, we offer customization options including mold size, power system, cutter device, feeding method and more. Just tell us your requirements and we’ll tailor the solution to choose the most suitable wood pellet press machine for you.