wood pellet manufacturing plant

Customized designs to optimize wood pellet quality, output and operational efficiency. Build your ideal wood pellet manufacturing plant with RICHI.

What is a wood pellet manufacturing plant?

— Richi Machinery —

brief introduction

Wood pellet manufacturing plant is a kind of complete system to turn raw biomass materials into the wood pellet. The raw biomass materials include wood, wood chip, sawdust and even some agricultural residues. The uniform and high-density wood pellet can be widely used as a fuel for burning, heating or industrial power generation. It is a kind of energy-saving line.

The typical production line include crushing, drying, pelletizing, cooling and packaging. It can cut the labor input and offer a continuous producing. This type of production line play an important part in reducing the industrial energy waste and supporting the sustainable energy development. It is very suitable for companies which looking for ways to enter the biomass fuel market.

Usage

The wood pellet manufacturing plant is mainly used to process various wood residues and agro-forestry biomass into renewable energy pellets, widely used in heating systems, biomass boilers, and power plants.

Raw materials

sawdust, wood shavings, wood chips, branches, bamboo powder, straw, palm shells, peanut shells, and other agro-forestry residues.

Production

0.3-45 (tons/hour)

pellet Size

1-12 (mm)

RICHI MACHINERY

Key Technical Features & Engineering Highlights of RICHI

Nowadays, more and more companies turned to choose a clean and efficient energy solution. That’s why choosing a right equipment is that important. A successful, well-designed wood pellet manufacturing plant is not only barely about turn the raw biomass material into uniform pellet but also about making a steady capacity output and a optimizing energy usage. Below we highlight the technical features that make RICHI pellet production systems stand out from other companies:

High automation level

The RICHI wood pellet making production line features advanced automation system, minimizing manual intervention while maximizing operational efficiency. From material wood pelleting to final packaging, the entire process is controlled through intelligent system in order to ensure precise and consistent production.

wide production capacity option

No matter what kind of business mode you are, we offers flexible capacity configurations ranging from 1 T/H to over 20 T/H. Whether you’re running a small startup business or a large-scale biomass enterprise, you can all find a type of production which is suitable for you. Each program can match your unique production goals.

energy-saving design

The whole production line adopts modular structure. Customers can flexibly upgrade or expand a part according to actual needs without replacing the whole system.

smart control & monitoring systems

The whole animal feed processing plant integrates complete automatic process from grinding, mixing, pelleting to cooling, crushing and packing. As a result, it significantly reduces labor costs while boost production efficiency.

professional engineering integration

The machine integrated noise reduction equipment and dust collect installations helps to create a eco-friendly working environment for the whole wood pellet manufacturing plant.

Stable & durable operation

Our machine are made of carbon steel and stainless steel which can provide a sterile working environment, offer a long service use even under heavy duty conditions.

RICHI MACHINERY

Core Benefits for End Users

Though the technical features highlight the structural design and operating steps, the real benefits under these high-tech is also deserve to known. What advantages these features actually brings you and what make RICHI truly stand out from other industry companies?

Let’s take a closer look of the real benefits these technologies can bring to you for setting a wood pellet manufacturing plant:

1. Effortless Operation, Focus on Business Growth

With advanced automation and intelligent control systems, you no longer need to spend extensive manpower or time on daily operations.

The whole line runs smoothly with real-time alerts, minimizing management burden so you can focus on expanding your market and business.

2. Flexible Investment, Maximum Output

Whether you are a start-up or an industrial scale operation, RICHI offers you capacity options. We can customize your wood pellet manufacturing plant from 0.3 to 45 T/H capacity. At the same time, all equipped units support and customize the process. There is always a solution to meet your needs.

Through energy-efficient design and yield optimization, you can get more pellets with less power. This gives you the fastest return on investment with the lowest operating costs.

3. Eco-Compliant & Future-Proof

With clean energy becoming the global standard, environmental compliance is a must. RICHI integrates dust removal, noise control and waste heat recovery technologies to ensure that your wood pellet production plant meets regulatory requirements.

On top of that, our production lines support long-term, sustainable operations that enhance your brand‘s environmental credentials.

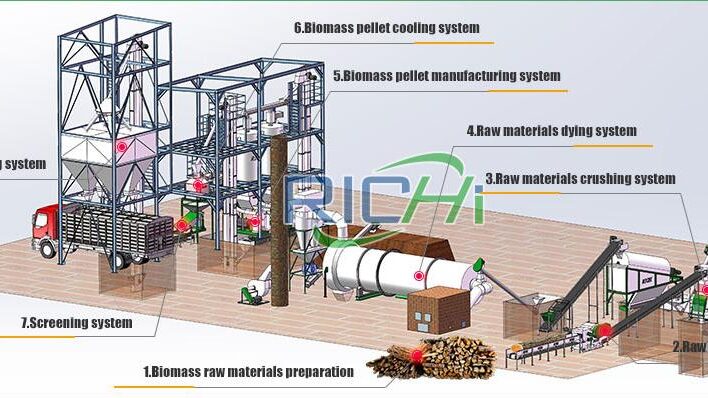

wood pellet manufacturing plant Components & Working Process

A complete wood pellet production line should equipped with several integrated machines and have a general working process. The machines include chipper, crusher, dryer, pelletizer, cooler, packer and so on. The typical working process is: raw material preparation-wood chipping &crushing-sawdust drying-wood pelletizing-wood cooling & packing. The concrete steps and the needed equipment are as follow:

1. Raw material preparation

Prepare all kinds of biomass materials, such as wood chips, sawdust tree branches and so on. In a word, any forestry wastes can be used as the processed material.

2. Chipping& Crushing step

If the diameter of some material is over 50mm, use a wood chipper to cut them into uniform sheets. If the raw material is light, such as the alfalfa, grass of the straw, use a specialized grass crusher.

3. Drying

In order to reduce the moisture content of the biomass, drying the raw material is very important. The best moisture content before pelletizing is about10%-15%, using a rotary dryer to achieve this goal.

4. Pelletizing

This is the core process of the whole wood pellet manufacturing plant. Fed the well-prepared biomass into the biomass pellet mill. Through pressure and heat, the pellet machine can compress dried biomass into uniform, high-density wood pellet.

5. Cooling

High-temperature treated pellets are too soft to be molded or packed, thus need a counter-flow feed pellet cooler to reduce their temperature. This step can make sure the pellet to be hard and durable, ready for the following process.

6. Packing

Using a rotary grading screen to separate out the powder feed. Then, the packaging scale system is activated to weigh, fill, and seal the pellet feed.

Customer Cases: Real Project Insights

RICHI projects are spread across more than 120 countries and regions worldwide, showcasing industry legends in the field of wood pellet manufacturing plant.

● biomass

2 T/H biomass pellet production line in Poland

RICHI go into the partnership with this medium company twice. Despite of the challenge of cold weather and the complex logistic, the project team still finished the whole production line install and commission work within six months.

Now the company has been running smoothly over two years. Our productions and service has won a prize among the local people.

→

● wood chip

2.5 T/H wood chip pellet production line in Romania

In order to meet the large poultry feed requirement, one large forestry company form Romania cooperate with RICHI to set a 2.5 T/H automatic production line. The customer have a need of processing multiple raw materials like wood, wood chip and grass. RICHI satisfied them with our profession technology and considerate service.

The production line include crushing, mixing, pelleting and packing. Based on customer’s actual space, RICHI customized the layout and offer the staff training, 7×24 hours on-line technical support.

→

● wood

12 T/H complete wood pellet manufacturing plant in Russia

To enhance the pellet quality and realize the biomass industry modernization, one large biomass process company contact us for design a 12 T/H automatic wood pellet making line. This project turned to produce compound wood pellet, supporting nation energy conservation plan.

RICHI adopted a modular design, combined the steel structure workshop with the multi-layout design. The production line also equipped with PLC auto-control system, making high efficiency and low labor cost possible.

→

How to Design & Build a Pellet Plant?

Building a wood pellet manufacturing plant may sound complex, but our company provides a smooth, step-by-step process designed for your success. It all starts with understanding your needs and our experts will work closely with you. Here are some questions should be considered before starting your own business:

- What type of the raw materials do you have access to(wood chips, sawdust, bamboo powder and so on) and are they available consistently or not?

- What is your intended production capacity per day?

- What is your total investment budget? Do you want the production more efficiency or cost less?

- Will the pellets be used for sale or only for your own needs?

- Are there any environmental standards or local regulations you need to meet?

Based on this, we create a tailored solution (include detailed layout design and equipment configuration). Once the plan is approved, we begin precision manufacturing, shipping, on-site installation and full system commissioning.

But we won’t settle for less. RICHI provides comprehensive operator training maintenance guidance and lone term technical support. We deliver turnkey projects that are efficient and scalable. Whether you’re building a medium facility or a large scale industrial plant, we will all satisfied you.

RICHI MACHINERY

General Parameters & Project Scope Reference for Setting a wood pellet manufacturing plant

We offers a menu of wood pellet manufacturing line so you get what you want! It’s a solutions-based approach to wood pellet production line design and manufacturing.

| specification | details |

| Production capacity | 1-20T/H |

| Automation level | Fully automatic(PLC controlled) |

| Energy consumption | 300-800 kW/H |

| Pellet density | 1.1-1.3 t/m³ |

| Pellet size | 1-8 mm |

| Moisture content for pelletizing | 10%-15% |

| Factory area | 2000-20000 ㎡ |

If you need help to choose the right animal feed pellet press, please contact us and tell us your daily output needs, we’ll recommend the best type match to you.

About us

Why to Cooperate with RICHI

RICHI Machinery integrates R&D, production sales and service. Our factory is equipped with advanced manufacturing equipment, a professional technical team and a strict quality control system to ensure every machine meets international standards.

RICHI not only offers high-quality wood pellet press machine but also supports customers with customized wood pellet manufacturing plant design, equipment configuration, on-site installation, technical training and after-sales service. Whether you run a small farm or a large-scale feed factory, we tailor solutions to your specific needs, raw materials, and production goals.

We believe in long-term partnerships built on trust, technology and success. With a customer-first mindset and continuous innovation, RICHI Machinery strives to be your most reliable partner in wood pellet processing. We warmly welcome customers all over the world to cooperate with us and grow together in the global pellet machinery market. Let us handle the hard part so that you can focus on growing your business.

Frequently Ask Question

Frequently Ask Question

1. How to choose the appropriate product?

Firstly, offer us your raw material type (sawdust, straw, rice hush, etc.) and to produce it in what form(powder or pellet). Second, estimate your monthly pellet output goal. This helps determine the scale of equipment.

You can also tell us about your rough budget and we will offer you the best design and equipment under the lowest cost. After the negotiation, we will give you the best efficiency and return on investment about the wood pellet manufacturing plant.

2. How do you manufacture poultry feed?

Yes, of course. We have a whole professional team to meet your requirement and serve the best production. Whether you’re building a small-scale unit or a large industrial plant we can all tailor the most suitable equipment size, texture and configuration for you. Just let us know some basic information like your product goals, available space and budget, we will not disappointed you.

3. Is the wood pellet production plant easy to maintain?

Yes, our feed production lines are designed with user-friendly operation and maintenance. Most part of the components are easy to access, clean and replace. We provide a full maintenance manual and video guides, we also manning technical commentator to help your staff handle routine inspections.

4. Can I expand the production line later?

Yes, absolutely. Our wood pellet manufacturing plants are designed with scalability. No matter what size of the business you’re running, whether you’re starting a small-capacity setup or a medium-sized facility, even a large-scale production project, we can make a promise that the layout allow for future expansion. For other word, if your initial business production is limited, you’re fully prepared for future scale-up. When your business grows, we also hope to start a new chapter of cooperation with you.

Any Question?

You can ask anything you want to know about Feedback