Wood Pellet Machine Germany

High quality wood pellet machine for sale Germany & Customized wood pellet machine Germany solutions

Introduction to Wood Pellet Machine Germany

A wood pellet machine is a specialized device designed to compress biomass materials such as sawdust, wood chips, and wood shavings into consistent pellets. These pellets are high-density fuels known for their excellent combustion efficiency, making them a sustainable energy source. In Germany, a country that champions renewable energy.

German pellet machine are vital for transforming forestry waste into high-quality fuel. By investing in advanced wood pellet machines in Germany, businesses can effectively process wood by-products and contribute to the country’s green energy ambitions.

Germany’s dedication to cutting carbon emissions and shifting toward renewable energy has spurred a marked increase in the demand for clean fuels like wood pellets. These pellets have become popular due to their high energy density, low moisture levels, and efficient combustion capabilities. With long winters creating a significant heating demand, wood pellets are particularly favored for residential heating, biomass boilers, and industrial power generation.

Moreover, Germany has set ambitious greenhouse gas reduction targets, fostering a growing market for sustainable fuels. Consequently, wood pellet production has evolved into a lucrative and eco-friendly business in the nation. By selecting the right wood pellet machines in Germany, companies can satisfy domestic energy needs while tapping into the rising international demand for biomass fuel.

Types of Wood Pellet Machine Germany Model We Offer

MZLH320 Wood Pellet Machine

- Capacity: 0.2–0.3 tons/hour

- Main Motor Power: 22 kW

- Arch-breaking Feeder Power: 2.2 kW

- Forced Feeder Power: 0.75 kW

- Ring Die Diameter: 320 mm

- Pellet Size: 4–12 mm

- Application: Suitable for small-scale wood pellet production, ideal for startups or workshops needing reliable pelletizing with low to moderate capacity.

MZLH350 Wood Pellet Machine

- Capacity: 0.3–0.5 tons/hour

- Main Motor Power: 37 kW

- Arch-breaking Feeder Power: 2.2 kW

- Forced Feeder Power: 0.75 kW

- Ring Die Diameter: 350 mm

- Pellet Size: 4–12 mm

- Application: Designed for small to medium wood pellet machine Germany operations, providing stable output and consistent pellet quality.

MZLH420 Wood Pellet Machine

- Capacity: 1.0–1.2 tons/hour

- Main Motor Power: 90 kW

- Arch-breaking Feeder Power: 3 kW

- Forced Feeder Power: 1.5 kW

- Ring Die Diameter: 420 mm

- Pellet Size: 4–12 mm

- Application: Ideal for medium-sized wood pellet plants requiring higher capacity and efficiency.

MZLH520 Wood Pellet Machine

- Capacity: 1.5–2.0 tons/hour

- Main Motor Power: 132 kW

- Arch-breaking Feeder Power: 3 kW

- Forced Feeder Power: 1.5 kW

- Ring Die Diameter: 520 mm

- Pellet Size: 4–12 mm

- Application: Suitable for medium to large-scale wood pellet production, offering robust performance and steady operation.

MZLH678 Wood Pellet Machine

- Capacity: 2.5–3.0 tons/hour

- Main Motor Power: 185 kW

- Arch-breaking Feeder Power: 3 kW

- Forced Feeder Power: 1.5 kW

- Ring Die Diameter: 673 mm

- Pellet Size: 4–12 mm

- Application: Perfect for large-scale wood pellet machine Germany production lines, delivering high output and excellent pellet quality.

MZLH768 Wood Pellet Machine

- Capacity: 3.0–4.0 tons/hour

- Main Motor Power: 250 kW

- Arch-breaking Feeder Power: 4 kW

- Forced Feeder Power: 1.5 kW

- Ring Die Diameter: 762 mm

- Pellet Size: 4–12 mm

- Application: Designed for industrial-level pellet plants requiring maximum capacity and continuous production.

Forestry Waste in German: A Valuable Resource for Biomass Energy

Germany’s forestry sector generates an abundance of wood waste, primarily from sawmills and wood processing industries. In the past, this waste was often disposed of through inefficient methods that raised environmental concerns. However, German wood pellet machines provide a more sustainable approach: transforming forestry by-products into valuable fuel pellets.

By investing in a dependable wood pellet machine in Germany, businesses can convert surplus wood materials into high-value biomass fuel. This not only minimizes waste accumulation and reduces disposal costs but also bolsters local recycling initiatives. Furthermore, by utilizing wood pellets as an alternative fuel, companies contribute to Germany’s green energy objectives while decreasing their reliance on fossil fuels. You can check more information on our youtube channel.

Wood Pellet Machine Germany Project

To better illustrate how RICHI solutions meet the demands of the German biomass market, let’s take a closer look at one of our representative wood pellet machine projects in Germany:

1

Production (ton/hour)

6 – 8

Pellet size (mm)

1 T/H Wood Pellet Machine Canada Solution

- Project Location: Germany

- Project Name: 1 T/H Wood Pellet Manufacturing Plant

- Raw Materials: Sawdust

- Production Capacity: 1 ton per hour

- Finished Pellet Size: 6–8 mm

- Workshop Size: 10 m × 6 m × 7 m

- Main Equipment:

- Rotary drum dryer

- 132 kW ring die wood pellet press machine

- Pellet cooler

- Automatic packing system

- Process Flow: Chipping → Drying → Pelletizing → Cooling → Screening → Packing

Project Background

Situated in southern Germany, the client is a small woodworking company that previously lacked a system for managing their wood waste. They sought a solution to transform sawdust into valuable biomass pellets for local heating markets.

After experimenting with a low-capacity biomass pellet making machine, they recognized the need for a more robust and reliable system capable of handling their raw materials while producing pellets that conform to the stringent standards of Germany’s green energy sector.

Tailored Solution by RICHI

To address their requirements, RICHI crafted a 1 T/H wood pellet machine solution specifically designed for small-scale production. The machine features an automatic lubrication system, an easy-to-use control panel, and a durable die design, which collectively ensure minimal maintenance and optimal productivity.

The installation was completed within 30 days, and RICHI provided on-site training to facilitate a seamless transition to the new system.

2

Production (ton/hour)

6

Pellet size (mm)

2 T/H Wood Pellet Machine Germany Solution

- Project Location: Germany

- Project Name: 2 T/H Wood Pellet Production Line

- Raw Materials: Wood chips and bark fines

- Production Capacity: 2 tons per hour

- Finished Pellet Size: 6 mm

- Workshop Size: 15 m × 8 m × 8 m

- Main Equipment:

- Crusher

- Rotary drum dryer

- 160 kW ring die wood chip pellet machine

- Counter-flow cooler

- Pellet screener

- Process Flow: Crushing → Drying → Pelletizing → Cooling → Screening → Packing

Project Background

This medium-sized enterprise in northern Germany produces a significant amount of wood chips and bark fines as by-products of its sawmill operations. The company aimed to enhance its waste disposal system by converting these materials into biomass pellets. However, the high moisture content in the raw materials presented a challenge for efficient pelletizing.

Tailored Solution by RICHI

RICHI stepped in with a customized solution: a 2 T/H wood pellet machine specifically designed for the conditions in Germany. This included an advanced drying system to effectively manage the high moisture content of the raw materials.

The 160 kW pellet mill, featuring a heavy-duty die and wear-resistant components, was built to withstand the abrasive nature of the bark, ensuring durability over time. Following installation, the system successfully transformed wood chips and bark into high-quality pellets, ready for export.

3

Production (ton/hour)

4 – 8

Pellet size (mm)

3 T/H Wood Pellet Machine Germany Solution

- Project Location: Germany

- Project Name: 3 T/H Wood Biomass Pellet Production Line

- Raw Materials: Sawdust and wood chips

- Production Capacity: 3 tons per hour

- Finished Pellet Size: 4-8 mm

- Workshop Size: 20 m × 12 m × 10 m

- Main Equipment:

- Pre-cleaning system

- Rotary drum dryer

- 200 kW wood pellet mill

- Counter-flow cooler

- Pellet packing system

- Process Flow: Pre-cleaning → Drying → Pelletizing → Cooling → Packing

Project Background

This client, situated in central Germany, runs a medium to large-scale wood processing facility. With the rising demand for biomass fuel both locally and internationally, they made the decision to invest in a 3 T/H wood pellet machine solution in Germany to expand their production capabilities.

However, they faced challenges as the raw materials often contained contaminants such as sand and small stones, which could lead to significant wear on the components of the pellet mill.

Tailored Solution by RICHI:

RICHI proposed a customized solution that featured a pre-cleaning system designed to eliminate contaminants from the sawdust and wood chips before they entered the dryer and pellet mill. The 200 kW pellet mill, fitted with a reinforced die and durable, wear-resistant rollers, ensured that the pellet quality remained consistently high.

Additionally, the automated packing system streamlined the production process, cutting down on labor costs and enhancing overall efficiency.

5

Production (ton/hour)

6 – 10

Pellet size (mm)

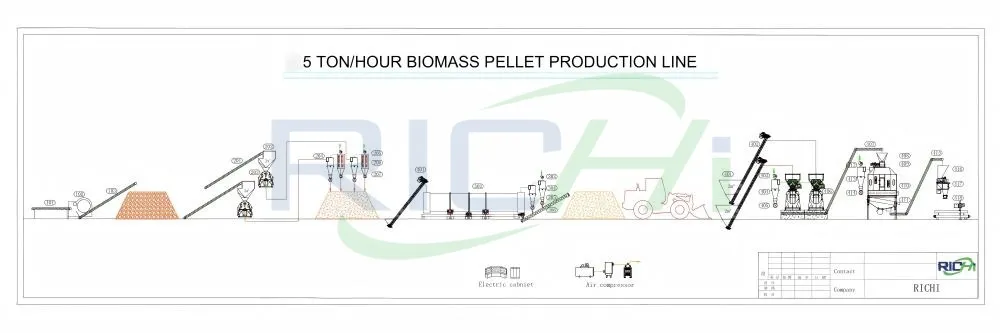

5 T/H Wood Pellet Machine Germany Solution

- Project Location: Germany

- Project Name: 5 T/H Wood Pellet Production Line

- Raw Materials: Mixed hardwood and softwood sawdust

- Production Capacity: 5 tons per hour

- Finished Pellet Size: 6-10 mm

- Workshop Size: 30 m × 15 m × 12 m

- Main Equipment:

- High-capacity crusher

- 2×160 kW rotary drum dryer

- 2×250 kW pellet mills

- Counter-flow cooler

- Fully automatic packaging system

- Process Flow: Crushing → Drying → Pelletizing → Cooling → Screening → Packing

Project Background

Nestled in the forest-rich region of Bavaria, Germany, our client faced the challenge of expanding their pellet production capabilities to keep up with the surging demand for wood pellets in Europe and Japan.

Although the facility was already generating significant amounts of hardwood and softwood sawdust, they were in need of an effective method to convert these by-products into valuable biomass fuel.

Tailored Solution by RICHI

For this ambitious 5 T/H project, RICHI recommended installing two 160 kW rotary drum dryers. These dryers provided the necessary capacity to efficiently process large volumes of raw material with varying moisture levels. To ensure consistent pellet quality while reducing energy consumption, we also installed two 250 kW pellet mills designed for high output.

The entire wood pellet machine Germany system was equipped with an automated control setup, allowing for easy monitoring and maintenance, which ensured smooth operation and optimal production efficiency.

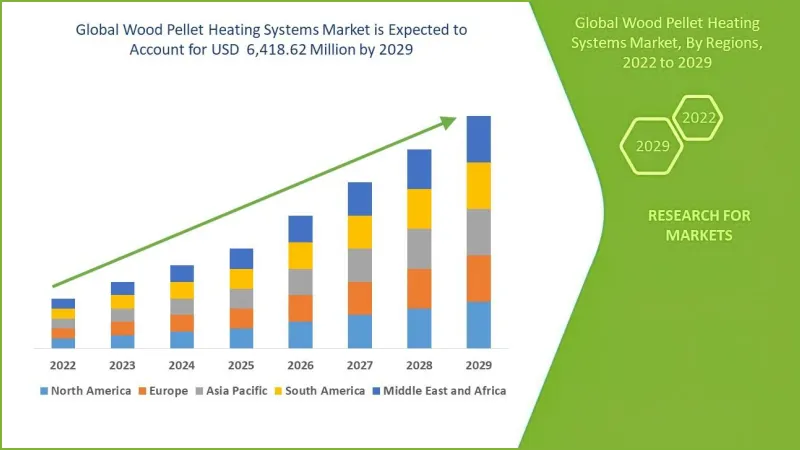

Pellet Machine Market Outlook in Germany

Germany’s Growing Demand for Wood Pellets

Germany’s wood pellet market is growing steadily due to the rising demand for renewable and sustainable energy. As a leading country in environmental policy and energy transition, Germany is investing heavily in biomass energy. Recent data shows that the production and consumption of wood pellets have increased significantly, with Germany being a major player in both domestic use and exports.

Focus in Germany’s Wood Processing Industries

Germany’s timber and wood processing industries are changing. The focus is shifting from traditional timber exports to value-added products like wood pellets. This change is driven by economic opportunities and stricter environmental rules that encourage the use of wood by-products, such as sawdust, wood chips, and bark. Therefore, businesses need to invest in advanced wood pellet press machines to maximize the value of these by-products and support the country’s green energy goals.

Export Market & International Demand

Wood pellet machine Germany are mainly exported to other European Union countries and emerging markets in Asia. Germany’s commitment to reducing carbon emissions through renewable energy makes it an attractive market for wood pellet producers. The need for clean and efficient biomass fuel is expected to increase, creating a higher demand for quality wood pellet machines in the country.

Government Support & Policy Incentives

The German government supports biomass energy production with financial incentives, subsidies, and grants to help businesses adopt eco-friendly technologies. The push for greater energy efficiency and less reliance on fossil fuels is also driving the market. More households and industries are using wood pellets for heating, power generation, and large-scale biomass boilers, making pellet production a more profitable option for businesses.

Future Outlook & Market Growth

With the emphasis on sustainability, the demand for wood pellet machine Germany will likely continue to grow. Companies that invest in reliable and efficient pellet machines can better meet the strict standards set by domestic and international markets. With strong infrastructure and supportive policies, Germany’s wood pellet industry will remain a key part of the European bio-economy, providing many opportunities for producers and exporters in the future.