Wood Pellet Machine Canada

High quality wood pellet machine for sale Malaysia & Customized wood pellet machine Canada solutions

Introduction to Wood Pellet Machine Canada

What Is a Wood Pellet Machine?

A wood pellet machine is a specialized device designed to compress forestry waste such as sawdust, wood shavings, and wood chips into high-density pellet fuel. For Canadian businesses, choosing the right wood pellet machine Canada means turning loose wood materials into uniform pellets with excellent combustion efficiency. These machines help maximize the value of forestry by-products and produce clean energy that meets growing market demand.

Why Are Wood Pellets Popular in Canada?

The wood pellets produced by these machines are environmentally friendly fuel. They have high density, low moisture content, and can burn very efficiently. Widely used for residential heating, biomass boilers, and large-scale power generation. Wood pellets are especially suitable for cold-climate countries rich in resources like Canada. With the increasing focus on clean energy, more Canadian clients are paying attention to wood pellet processing equipment.

Wood Waste Management in Canada: A Value Chain

Forestry Waste: A Resource Waiting to Be Utilized

Forestry is a major industry in Canada. Sawmills and wood processing plants generate large amounts of wood waste annually. Traditional disposal methods are often inefficient and environmentally challenging. By investing in a reliable wood pellet machine Canada, companies can locally process wood waste into valuable pellet fuel. This reduces transportation and storage costs while supporting local recycling and energy use.

Such solutions are vital in resource-rich provinces like British Columbia, Alberta, and Quebec. Moreover, the clean and efficient combustion of pellet fuel makes it an ideal choice to meet Canada’s increasingly strict environmental regulations.

Turn Waste into Profit with Pellet Machines

We, RICHI Machinery, is a specialized Chinese manufacturer in biomass energy equipment. We understand the diverse needs of Canadian clients. Our pellet press Canada products are designed to handle various local softwood and hardwood raw materials. Such as spruce, pine, poplar, and maple. Equipped with intelligent control systems and energy-efficient motors, our machines perform reliably even in cold and humid conditions.

If you manage a sawmill or operate in wood or agricultural residue processing, you might face challenges such as waste accumulation and costly disposal. Investing in a pellet making machine Canada project can turn these wastes into saleable pellet fuel. It will also open new revenue streams while solve waste management problems.

Wood Pellet Machine Canada projects

To better illustrate how RICHI solutions meet the demands of the Canadian biomass market, let’s take a closer look at one of our representative wood pellet machine projects in Canada:

1

Production (ton/hour)

8

Pellet size (mm)

1 T/H Wood Pellet Machine Canada Solution

- Project Location: Canada

- Project Name: 1 T/H Wood Pellet Production Line

- Raw Materials: Wood chips

- Production Capacity: 1 ton per hour

- Finished Pellet Size: 8 mm

- Workshop Size (L × W × H): 18 m × 7 m × 8 m

- Main Equipment:

- 1.5×12m rotary drum dryer

- 132kW ring die wood pellet press machine

- Pellet cooler

- Vibrating screener

- Automatic packing system

- Process Flow:

- Chipping → Drying → Pelletizing → Cooling → Screening → Packing

Project Background

This Canadian client is based in a province rich in forest resources. He originally ran a small woodworking and sawmill business. As the biomass fuel market began to grow, he started planning to turn the sawdust that was previously wasted into higher-value fuel products.

However, transitioning from traditional woodworking to wood pellet machine Canada project came with many challenges. The biggest issue was his lack of experience with pellet machinery. He was especially concerned about operational complexity and equipment durability. In the past, he had tried using a small pellet machine, but it was difficult to operate and produced pellets with inconsistent quality.

Considering Canada’s cold climate, along with the strict quality requirements for pellets used in stoves and boilers, the client needed a machine that was both reliable and easy to operate. A stable system would help him handle the tough working conditions and meet the necessary fuel standards.

Installation & Operation Detail

- Project Start Time: June, 2023

- Installation Period: 30 days

- RICHI On-Site Engineers: 2 professional installation and training engineers

- Workshop Layout: Compact medium-scale layout, optimized for 18 m × 7 m × 8 m space

- Occupied Space by RICHI Equipment: Entire production line configured within one workshop area

- Total Power Consumption: 229 kW

- Labor Requirement: 3 workers per shift

Tailored Solution by RICHI

To address the client’s concerns and site conditions, RICHI developed a custom 1 T/H wood pellet machine Canada solution.

01 Pellet Machine Optimization

The 132kW ring die wood chip pellet machine was fitted with reinforced bearings, a wear-resistant die. What’s more, it also has an automatic lubrication system. This significantly reduced maintenance intervals and prevented premature wear.

02 User-Friendly Operation

RICHI integrated an intelligent control panel with one-button start/stop indicators. All core machine parameters were pre-set and locked to prevent errors by untrained staff.

03 Compact Layout Design

The equipment was arranged linearly within the client’s narrow workshop. Modular installation reduced space use while ensuring easy access for cleaning and maintenance.

04 Training & Documentation

RICHI engineers created customized manuals in both English and pictorial format. We set 2 engineer to Canada guide the client. Thus make it easier for the non-technical staff to perform operations and checks.

This customized solution delivered a reliable, easy-to-run pellet production line suitable for clients with little technical background. It also ensured smooth production under Canadian climate conditions.

Why It Matters

This wood pellet machine Canada project demonstrates how small sized businesses can successfully shift from traditional wood processing to biomass energy production with support from RICHI. For clients with limited experience, ease of operation and equipment durability are often the top priorities.

RICHI provided a customized solution based on the client’s specific needs. We helped transform wood waste into high-quality biomass pellets efficiently. Resulting in a production system that is both high-performing and easy to manage.

More importantly, this case also highlights how localized pellet production supports Canada’s renewable energy goals. At the same time, it helps reduce waste generated by sawmills. For businesses looking to make a similar transition, choosing reliable pellet equipment is essential. By offering user-friendly machines, robust designs, and full technical support, RICHI is helping more Canadian enterprises move toward a sustainable energy future.

2 – 2.5

Production (ton/hour)

4 – 6

Pellet size (mm)

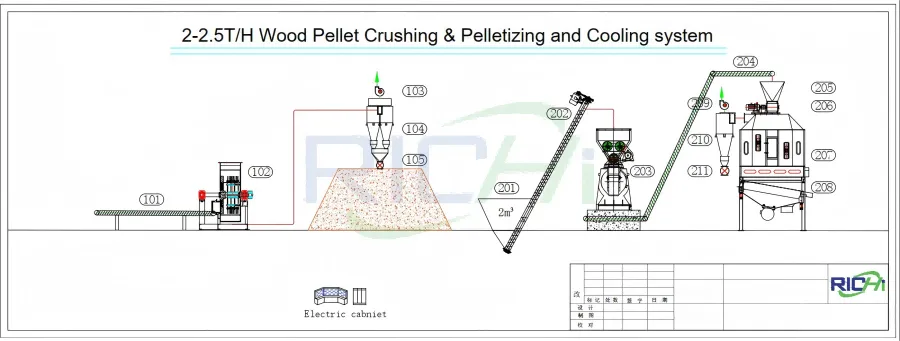

2-2.5 T/H Wood Pellet Machine Canada Solution

- Project Location: Canada

- Project Name: 2-2.5 T/H Wood Pellet Manufacturing Plant

- Raw Materials: Sawdust, wood chips, and bark fines

- Production Capacity: 2 tons per hour

- Finished Pellet Size: 4–6 mm

- Workshop Size (L × W × H): 9 m × 5 m × 10 m

- Main Equipment: Drum screener / Crusher / Dryer / Pellet machine / Cooler / Packaging system

- Process Flow:

- Crushing → Drying → Pelletizing → Cooling → Screening → Packing

Project Background

This client operates a medium-sized wood processing facility in Eastern Canada. Due to long, harsh winters, raw materials such as sawdust and wood chips are often stored outdoors. Over time, snow and frost accumulate on the material surface, and bark, sand, and other impurities can get mixed in.

When the client decided to invest in a 2-2.5 T/H wood pellet machine Canada production line, they faced two major concerns: first, surface frost on raw materials would reduce drying efficiency and affect stable operation; second, impurities caused severe wear on pellet machine dies, leading to frequent downtime and higher maintenance costs.

The client had previously experimented with small pellet mills, but gave up due to poor mold durability and unstable output. For this project, they needed a more robust and adaptable pelletizing system—one that could handle frosted and impure materials while delivering consistent, high-quality pellets for both heating and export.

Production Process

- Project Start Time: June 2023

- Installation Period: 30 days

- RICHI On-Site Engineers: 2 professional installation and training engineers

- Workshop Layout: Medium-scale compact design optimized for 18 m × 7 m × 8 m space

- Occupied Space by RICHI Equipment: Entire system integrated within one production area

- Total Power Consumption: 280 kW

- Labor Requirement: 2 workers per shift

Tailored Solution by RICHI

To address the challenges caused by frost and impurities in outdoor-stored biomass, RICHI provided a customized pelletizing solution:

01 High-Wear-Resistant Die Design

The pellet mill was equipped with RICHI’s dual-layer alloy steel die, specifically engineered to handle abrasive and contaminated raw materials. The structure ensures both anti-corrosion and high-pressure resistance, delivering consistent performance even after long hours of use.

02 Precision Lubrication System

The pellet mill features an intelligent lubrication system that continuously monitors the running status of the die and rollers. Timely oil injection minimizes wear and extends component lifespan.

03 Optimized Energy Efficiency

To meet the client’s energy concerns, we adopted a 132 kW high-efficiency motor that balances durability with reduced power consumption.

Through this customized approach, the client successfully overcame Canada’s typical raw material storage challenges. After six months of continuous operation, the die still retained its shaping quality and productivity. The final pellets are now ready for direct export to the European market.

Why It Matters

This wood pellet machine Canada project demonstrates our deep understanding of regional raw material characteristics and the real-world technical issues that clients face. In Canada, outdoor-stored biomass like sawdust often contains frost and various impurities. These elements accelerate wear on pellet mill dies and jeopardize the entire production process. This is a common pain point among small and medium-sized forestry businesses across the country.

To solve this, RICHI integrated an enhanced pre-cleaning system and provided custom-made wear-resistant dies. This fundamentally solved the problems of rapid wear and poor pellet formation. The result was a stable and efficient production flow that could reliably turn inconsistent materials into export-quality wood pellets.

More importantly, this project highlights the adaptability of RICHI pellet machines in complex environments. Our wood pellet machine all engineered to meet the real challenges Canadian producers face. With this, the client transformed forestry by-products into long-term economic value, proving that RICHI machines deliver both performance and peace of mind.

3

Production (ton/hour)

6 – 10

Pellet size (mm)

3 T/H Biomass Wood Pellet Machine Canada Project

- Project Country: Canada

- Project Name: Full Automatic Biomass Wood Pellet Line

- Application: Biomass pellet production for clean energy export

- Production Capacity: 3 tons per hour

- Finished Pellet Size: 6.0–10.0 mm

- Raw Materials: 50% moisture wood chips and sawdust

- Main Equipment Configuration: Wood crusher, shifter, dryer, storage bin, wood biomass pellet making machine, cooler, shifter, automatic packing system

- Process Flow: Crushing → Screening → Drying → Pelletizing → Cooling → Screening → Packing

Project Background

The client is a Canadian sawmill and wood processing company that has long focused on log cutting and lumber production. This process consistently generated large volumes of by-products—mainly sawdust and wood chips with 50% moisture content—which were previously sold at low prices or discarded.

With growing international demand for biomass fuel, particularly in markets like the UK, Japan, and Italy, the client identified a valuable opportunity. They chose to upgrade their business model by investing in a biomass pellet project that could turn waste into profit.

However, challenges included limited factory space (originally designed for sawmilling), complex building structures, and raw material moisture levels. The client needed a compact, export-standard production line that could operate efficiently under spatial constraints. This called for a fully customized wood pellet mill Canada solution.

Installation & Operation Detail

- Project Start Date: August 1, 2023

- Installation Period: 60 days

- RICHI On-Site Engineers: 1 senior engineer dispatched

- Occupied Space by RICHI Equipment: 26m (L) × 20m (W) × 12m (H)

- Total Power Consumption: 200 kWh

- Labor Requirement: 6 workers

Tailored Solution by RICHI

To meet the client’s strict spatial and raw material requirements, RICHI Machinery provided a fully customized 3 T/H automatic biomass wood pellet machine Canada production line with the following tailored solutions:

01 Factory Layout Customization

The client’s sawmill workshop had limited vertical and horizontal space. Our engineering team redesigned the layout to fit all core equipment—including drying and pelletizing sections. Within a 26 m (L) × 20 m (W) × 12 m (H) area.

We adjusted the material flow direction to a U-shape layout to optimize space utilization without affecting process continuity.

02 High-Moisture Material Handling

The raw materials (wood chips and sawdust) had a moisture content of up to 50%. We selected and configured a high-efficiency rotary drum dryer with a custom-designed feeding and exhaust system to handle the heavy wet load.

The drying section was extended and reinforced with a double-layer insulation system to improve thermal efficiency and reduce energy loss.

03 Moisture Buffer Bin Integration

Between the drying and pelletizing sections, we added a moisture buffer bin to ensure consistent feeding and moisture uniformity, avoiding feeding surges and improving pellet stability.

This solution allowed the client to transform high-moisture sawmill by-products into high-quality wood pellets suitable for export, within a spatially constrained environment, and with minimal operator intervention.

Client Perspective

"Your team have helped us to turn our waste into profit. The system is running stably and the first batch of export passed the inspection. We are planning to add a new high-grade pellet production line."

5

Production (ton/hour)

6

Pellet size (mm)

5 T/H Biomass Wood Pellet Machine Canada Project

- Project Location: Canada

- Project Name: 5T/H Wood Pellet Production Line

- Raw Materials: Hardwood sawdust and softwood chips (mixed)

- Production Capacity: 5 tons per hour

- Finished Pellet Size: 6 mm

- Workshop Size (L × W × H): 25 m × 12 m × 15 m

- Main Equipment:

- High-capacity crusher

- Rotary drum dryer (2.2×22m)

- MZLH520 Wood Pellet Mill (160kW × 2 sets)

- Counterflow cooler

- High-efficiency vibrating screener

- Fully automatic packaging line

- Customized central control cabinet

- Process Flow:

- Crushing → Drying → Pelletizing → Cooling → Screening → Packing

Project Background

The client is a large-scale wood processing company based in British Columbia, Canada. With increasing demand for wood pellets in Japan and the European Union, the company aimed to expand its biomass fuel business through the construction of a 5T/H production line tailored for export.

However, two critical concerns emerged during project planning:

- Pellet Quality Consistency: To meet stringent export standards, the client needed assurance that finished pellets would maintain uniform density, shape, and ash content.

- Energy and Automation Integration: The facility required that the entire system be compatible with the site’s existing power infrastructure, while also supporting centralized control and automated fault monitoring to streamline daily operations.

Installation & Operation Detail

- Project Start Time: March, 2024

- Installation Period: 45 days

- RICHI On-Site Engineers: 3 experts in electrical control and mechanical assembly

- Workshop Layout: Industrial layout optimized for three production zones

- Occupied Space by RICHI Equipment: 80% of workshop

- Total Power Consumption: 680 kW

- Labor Requirement: 3–4 workers per shift with centralized monitoring station

Tailored Solution by RICHI

To address the client’s dual concerns of export-grade pellet quality and electrical automation, RICHI provided the following customized wood pellet machine Canada solutions:

01 Precision Pelletizing Technology

Equipped with two MZLH520 wood pellet mills (160kW each), featuring heavy-duty dual ring die systems and reinforced compression rollers to ensure uniform pellet formation.

The system was calibrated to achieve optimal compaction, reducing fines and ensuring consistent bulk density.

02 Pellet Quality Control:

Added a precision counter flow cooler and high-frequency vibrating screen to enhance uniformity in cooling and final particle separation.

Pellet ash content and durability were tested during commissioning to ensure compliance with EU and Japanese standards.

03 Electrical System Customization

The entire production line was equipped with a centralized electric control cabinet using PLC control. This system allows unified management of all core equipment, including pellet mills, dryers, coolers, and packaging units..

The PLC panel is easy to operate and supports real-time monitoring of basic operating parameters such as motor status and fault alarms, helping reduce operator workload and improve overall production reliability.

Why It Matters

This project highlights RICHI’s ability to deliver export-oriented pellet solutions that meet the strictest international standards. By engineering for consistency in pellet density and ash content, RICHI ensures that clients are not only producing pellets but producing pellets that pass customs inspections and meet buyer specifications—an essential factor in premium export markets like Japan and the EU.

Moreover, the successful integration of the pellet production line with the client’s factory-level automation and power infrastructure reflects RICHI’s engineering versatility. From process layout to control systems, every component was designed with efficiency, compatibility, and long-term operability in mind. For high-output producers in Canada aiming to enter the global biomass fuel market, this project stands as a benchmark of what a professional-grade pellet mill system can achieve. You can check more cases on our Youtube channel.

Pellet Machine Market Outlook in Canada

Driven by the growing global demand for clean and renewable energy, Canada’s wood pellet market is steadily expanding. Data from Natural Resources Canada (NRC) shows that since 2016, wood pellet exports have increased significantly. The main export destinations include countries leading the energy transition, such as the United Kingdom, Japan, and Italy. Both European and Asian markets offer broad opportunities for Canadian wood pellet producers.

At the same time, Canada is improving the utilization of wood by-products like sawdust and wood chips year by year. The wood processing industry is shifting from traditional log exports toward producing higher-value pellet fuels. This change creates a strong need for reliable and efficient wood pellet machine Canada solutions. Such machines are essential for businesses aiming to increase the value of their forestry by-products.

Currently, Canada’s wood processing sector is undergoing structural changes. Government policies actively support the development of biomass energy and encourage companies to adopt more environmentally friendly production methods. Market trends also promote the growth of green exports. Thus further increase the appeal of pellet fuel projects. Under these conditions, investing in biomass pellet production and high-quality wood pellet machine. Canada becomes an ideal choice for companies seeking sustainable growth and market expansion.

For Canadian businesses that want to comply with environmental policies and tap into growing international markets, wood pellet machine Canada projects provide a clear path forward. By using suitable wood pellet machines Canada, companies can reduce waste and produce clean fuel that meets global standards. In the coming years, this industry is expected to become a key pillar of Canada’s bio-economy and offer profitable opportunities for exporters.

Types of Wood Pellet Machine Canada Model We Offer

MZLH320 Wood Pellet Machine

- Capacity: 0.2–0.3 tons/hour

- Main Motor Power: 22 kW

- Arch-breaking Feeder Power: 2.2 kW

- Forced Feeder Power: 0.75 kW

- Ring Die Diameter: 320 mm

- Pellet Size: 4–12 mm

- Application: Suitable for small-scale wood pellet production, ideal for startups or workshops needing reliable pelletizing with low to moderate capacity.

MZLH350 Wood Pellet Machine

- Capacity: 0.3–0.5 tons/hour

- Main Motor Power: 37 kW

- Arch-breaking Feeder Power: 2.2 kW

- Forced Feeder Power: 0.75 kW

- Ring Die Diameter: 350 mm

- Pellet Size: 4–12 mm

- Application: Designed for small to medium wood pellet machine Canada operations, providing stable output and consistent pellet quality.

MZLH420 Wood Pellet Machine

- Capacity: 1.0–1.2 tons/hour

- Main Motor Power: 90 kW

- Arch-breaking Feeder Power: 3 kW

- Forced Feeder Power: 1.5 kW

- Ring Die Diameter: 420 mm

- Pellet Size: 4–12 mm

- Application: Ideal for medium-sized wood pellet plants requiring higher capacity and efficiency.

MZLH520 Wood Pellet Machine

- Capacity: 1.5–2.0 tons/hour

- Main Motor Power: 132 kW

- Arch-breaking Feeder Power: 3 kW

- Forced Feeder Power: 1.5 kW

- Ring Die Diameter: 520 mm

- Pellet Size: 4–12 mm

- Application: Suitable for medium to large-scale wood pellet production, offering robust performance and steady operation.

MZLH678 Wood Pellet Machine

- Capacity: 2.5–3.0 tons/hour

- Main Motor Power: 185 kW

- Arch-breaking Feeder Power: 3 kW

- Forced Feeder Power: 1.5 kW

- Ring Die Diameter: 673 mm

- Pellet Size: 4–12 mm

- Application: Perfect for large-scale wood pellet machine Canada production lines, delivering high output and excellent pellet quality.

MZLH768 Wood Pellet Machine

- Capacity: 3.0–4.0 tons/hour

- Main Motor Power: 250 kW

- Arch-breaking Feeder Power: 4 kW

- Forced Feeder Power: 1.5 kW

- Ring Die Diameter: 762 mm

- Pellet Size: 4–12 mm

- Application: Designed for industrial-level pellet plants requiring maximum capacity and continuous production.