1 T/H Tofu Cat Litter Production Line in Malaysia

Discover how RICHI built a 1 T/H tofu cat litter production line in Malaysia with a customized design, advanced pelletizing line and efficient production solution.

Project Overview

RICHI Manufacture has started to build a prospect of tofu cat litter production line in Malaysia in April, 2023. The customer is very satisfied with the complete fish feed plant and has made a profit.

1

Production (ton/hour)

2 – 4

Pellet size (mm)

- Project Country: Malaysia

- Project Name: Tofu Cat Litter Plant

- Production Capacity: 1 ton per hour (T/H)

- Raw Materials: Okara, guar gum, calcium carbonate, starch, and blended additives

- Final Products & Sizes: 2 mm and 4 mm pellets

- Main Equipment: Screw conveyor, mixer, pellet machine, cooler, and packing machine

- Project Start Date: April 15, 2023

- Installation Period: 15 days

- Number of Engineers for Installation Support: 3 engineers

- Client’s Factory/Workshop: Located in Klang Valley, Malaysia, with a dedicated workshop area for assembly and testing

- Project Footprint (L × W × H): 40 m × 20 m × 8 m

- Power Consumption: 60 kW

- Operating Manpower Required: 2 operators per shift

Client Background: Malaysian Tofu Cat Litter Manufacturer

This client is a well-known pet supplies manufacturer based in Malaysia that initially focused on the local market. With more households adopting pets, people started paying more attention to practical products like cat litter.

To diversify their offerings and tap into new opportunities, the company decided to launch a tofu cat litter line to meet the rising demand for lightweight, low-dust, and easy-to-clean litter.

After experiencing steady growth locally, the client noticed an increasing interest in eco-friendly cat litter in nearby Southeast Asian countries like Singapore, Thailand, and Indonesia.

To meet this demand, the company invested in a tofu cat litter production line in Malaysia with a capacity of 1 ton per hour. This investment aims to boost production capacity and ensure consistent quality. Thus to support the company’s strategy of serving both local and international markets.

The project is located in the Klang Valley, which is Malaysia’s main industrial and logistics center. Being close to major ports and transport networks makes it easy to access supply chains and export routes. The client takes advantage of Malaysia’s strong trade position within ASEAN and globally. They aim to strengthen its presence in the local market while expanding into new overseas markets.

Raw Materials for Tofu Cat Litter Plant

The tofu cat litter production line mainly uses five key raw materials:

Okara

This is a byproduct of the tofu-making process. Its high fiber content and biodegradable nature make it an excellent foundational material for eco-friendly cat litter.

Guar Gum

Extracted from guar beans, this natural thickening agent aids in binding the materials together and enhances the strength of the pellets.

Calcium Carbonate

Often used as a filler and to neutralize odors, calcium carbonate helps the cat litter soak up moisture and keeps things smelling fresh.

Starch

Starch comes from corn or other plants and acts as a natural binder, helping the pellets stay strong and keep their shape.

Blended Additives

Additives could include scents or antibacterial ingredients that boost the litter’s performance and improve the overall experience for cat owners.

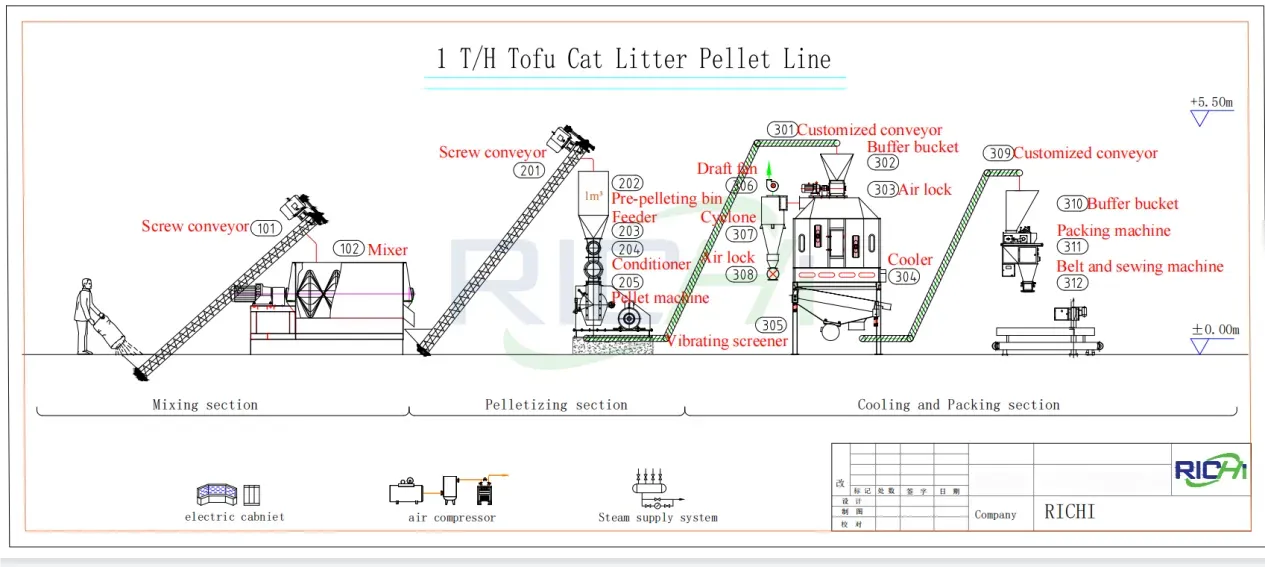

Production Process & Equipment Layout

To meet the client’s needs, RICHI put together a customized 1 ton per hour (1 T/H) fully automated tofu cat litter production line in Malaysia. The entire setup has three main parts: mixing, pelletizing, and cooling & packing. All the equipment that comes into contact with the materials is made from food-grade or corrosion-resistant materials. Make sure the products are eco-friendly, safe, and ready for export.

1. Mixing Section

First up, raw materials are moved by screw conveyors into a double-shaft mixer. There’s a pre-pelleting bin to temporarily hold the mixed materials. It can help keep everything flowing smoothly and ensures a good mix.

- Raw material moisture is keep between 12-15%

- You can adjust the mixing time and speed for consistent batch quality

- The sealed equipment interfaces help keep dust and pollution at bay

2. Pelletizing Section

Next, the mixed materials get fed by a screw feeder into a conditioner where we add steam or water to adjust the moisture. Then the cat litter pellet machine (MZLH420 model) pelletize the raw material, which is the core of the process.

- Main motor power is 60 kW

- Die hole sizes are between 1.5-3.0 mm; pellet lengths are 2-4 mm

- Pelletizing rate is at least 95%; powder rate is 3% or less

- A vibrating screener aims at screen the pellet to remove any fines and impurities

3. Cooling & Packing Section

Once pelleted, the product goes through a counter-flow cooler that drops the temperature from around 70°C to room temperature to avoid clumping and spoilage. After that, the pellets are send to an automatic packing machine for filling and sealing based on volume.

- Packing sizes include 2L, 5L, 10L, etc.

- There’s an option for a belt conveyor and sewing machine for easy bag sealing

- The whole process is very automated, needing just 1-2 operators for packing

4. Line Integration Features

The entire tofu cat litter production line in Malaysia uses screw and belt conveyors for a compact layout and seamless flow.

Plus, it supports continuous operation with steady power consumption, making it perfect for export-oriented production.

RICHI Customized Tofu Cat Litter Plant Solutions

To help our client tackle both local and international markets, RICHI made several smart tweaks to boost pellet-making performance, improve packaging efficiency, and enhance overall production reliability. In this way to ensure top-notch quality of the whole tofu cat litter production line in Malaysia and the ability to meet growing demand.

1. Stable Product Quality and High Production Efficiency

Local raw materials like okara and other additives can vary in moisture and texture, which sometimes results in poor mixing and uneven pellets. This can lead to too much powder and less market appeal.

To fix this, we set up a high-efficiency twin-shaft mixer to guarantee everything blends well. The 60 kW pelletizer with a specially designed die hits a pelletizing rate of over 95% and keeps powder content below 3%, cutting down on waste and ensuring quality stays consistent.

Plus, the counter-flow cooler keeps pellet hardness stable, prevents deformation, and makes sure the final product meets both local and export standards.

2. Precision Pelletizing System for Consistent Output

In the pelletizing section of the whole tofu cat litter production line in Malaysia, we use a strong stainless-steel ring die with a hole diameter of 2.5–3.0 mm, built to last even with heavy use.

The length of the final pellets is controlled between 2–4 mm, making them look neat and easy for cats to use.

With high efficiency and minimal powder generation, this system cuts down on rework and waste, boosting product appeal.

3. Improved Packing Efficiency for Big Shipments

To keep production flowing smoothly and meet export-quality packaging standards, we designed a packing system that includes a belt conveyor, buffer bucket, packing machine, and automatic sewing machine.

It is worth mention that the buffer bucket acts as a storage spot to keep materials flowing smoothly between continuous cooling and intermittent packing.

This setup helps avoid blockages or downtime while reducing pellet breakage and dust, ensuring the product stays in great shape before it’s packed up.

After-Sales Service & Training Support

We sent three of our technical engineers over to the Malaysian site to oversee the whole installation process.

Once everything was set up and running, we provided hands-on training for the client’s operators. So they could get the hang of operating the tofu cat litter production line in Malaysia like pros.

We also made sure to train the maintenance team on how to keep things running smoothly. And how to troubleshoot any issues that might pop up to ensure everything stays stable in the long run.

Taking into account the equipment features and what the client needed. We put together a personalized maintenance schedule. And outlining what needs to be maintained, when, and who’s responsible for it.

Our after-sales support team stays in touch with the client in Malaysia on a regular basis to check on the equipment status. We provide technical advice, and help out with any issues quickly.

Aside from the consumable wear parts, the production line includes a 1-year free warranty. Also ongoing technical support for life from our company.

client Feedback & Investment Overview of the Tofu cat litter production line in Malaysia

The Malaysian tofu cat litter manufacturer is really happy with the performance of their 1 T/H production line. They’ve noticed that the pellet quality is stable, it operates efficiently, and the design is user-friendly, which has helped boost their production capacity and cut down on labor costs.

They really liked the custom features, especially the buffer bucket in the packing section, which made packaging quicker and kept the product intact.

When it comes to investment, the client mentioned that the high automation and strict quality control of the line have greatly reduced waste and rework. This means a shorter production cycle and a fast return on their investment. Thanks to this line, they’re not only meeting local demand but also making strides in export markets like Singapore and Thailand.

Overall, this project has really strengthened their market position and set them up for future growth in the area.

“We have been very impressed with RICHI Machinery’s professionalism and technical support throughout the installation and commissioning of our tofu cat litter production line in Malaysia. The equipment runs smoothly with consistent pellet quality, which has helped us expand both our local and export markets. Their after-sales service is timely and very helpful, making us confident in long-term cooperation. Highly recommended!”

Market Outlook for Tofu cat litter production line in Malaysia

*Global Cat Litter Expected Market Chart

Domestic Demand Growth

The number of households with pets in Malaysia keeps climbing, according to the Department of Statistics Malaysia (DOSM). As more people get furry friends, they’re also looking for better pet care products, like cat litter.

People are leaning towards eco-friendly and convenient options, which is why tofu cat litter is gaining popularity. It’s biodegradable and creates less dust, making it a top choice. This trend opens up great opportunities for local manufacturers to innovate and meet the changing preferences of pet owners.

Export Potential

In the past few years, the appetite for sustainable, plant-based cat litter has really taken off, especially in big markets like North America, Europe, and across Asia-Pacific. Malaysia is in a great spot to tap into this demand. They have got easy access to high-demand markets thanks to the strong trade routes and free trade agreements.

With major ports like Port Klang, shipping stuff out in bulk is both cost-effective and efficient. Plus, as a member of the Regional Comprehensive Economic Partnership (RCEP), Malaysia enjoys some nice trade perks with countries like China, Japan, South Korea, and Australia.

The preferential tariffs under ASEAN Free Trade Agreements (AFTA) also make it easier to export to neighbors like Thailand, Indonesia, and Vietnam. By taking advantage of these trade deals and our strategic location, manufacturers can efficiently get tofu cat litter into regional markets and set up tofu cat litter production line in Malaysia in order to reach high-value global markets like the U.S., Canada, Germany, and the U.K.

Conclusion & Cooperation Invitation

Feeling the heat to meet the rising demand for lightweight, dust-free cat litter? Interested in finding a new growth opportunity in the competitive pet supplies game? Want to set up your own tofu cat litter production line in Malaysia? With more consumers opting for natural and sustainable pet care products, tofu cat litter is stepping up as a promising alternative to traditional clay litter.

Now couldn’t be a better time to dive into tofu cat litter production. With low production risks, a growing global demand, and a fit for eco-friendly branding, it’s a smart move for business expansion.

Whether you’re focused on local sales or eyeing regional exports, a high-efficiency, stable tofu cat litter production line from RICHI could give you a competitive edge—helping you grab market share more effectively and scale up with confidence. You can also find more solutions on our youtube channel.