Poultry Feed Mixer Machine

High quality poultry feed mixer machine & Customized animal feed production solutions

What is poultry feed mixer machine?

Poultry feed mixer machine is widely used for homogeneous mixing and is an important component in most feed production line. The machine is designed to blend various raw material like corn, cereal, wheat bran, corn flour even vitamins and additives into uniform powder.

The primary function of this kind of machine is to ensure each batch of animal feed is nutritionally balanced. It can be used for animals from livestock, poultry to aquatic animals. The effectiveness of feed mixing directly impacts the health and growth of animals.

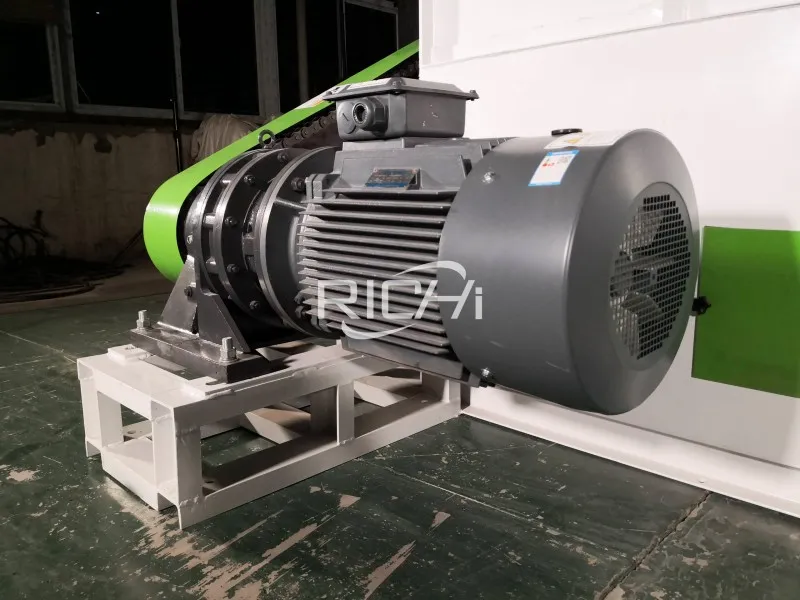

Therefore, to cooperate with a dependable company is very vital. At RICHI, our feed mixers have high precision, low residue and fast mixing cycles. We offer customized service and have all kinds of models. Our mixers can be seamlessly integrated into both small farm and large scale feed plants. Our mixers have customizable designs and optional features (such as liquid spraying or trace element addition). Hence ensures flexibility and performance and meets the changing needs of modern feed production.

Model

SLH, SLHSJ, SLHY, STHJ, ZGH

Power

4 – 45 kW

Capacity(T/H)

0.1-30 (tons/hour)

Raw material

corn, wheat, cereal, crushed grass, alfalfa meal, straw, oil seed, etc.

Raw Material size

powder or granule

Machine material

carbon steel or stainless steel

Why Do You Need a poultry feed mixer machine?

A poultry feed mixer machine plays an important role in ensuring animals get the balanced nutrients they need. If the ingredients are not mixed thoroughly, some animals may have nutritional imbalances — they may eat too much of this elements while not enough of another. This doing bad for their health and thus slowing your farm’s productivity as well. A good mixer helps you combine raw materials into balanced feed where ensure animals receive balanced nutrients in every bite of their feed. So choosing one durable and good mixer is very necessary.

In a feed mixing system, a mixer is the core equipment. The choose of the mixer directly affects the quality and use performance of the final feed product. It has many advantages like maintains consistent quality, reduces raw material waste and improves feed efficiency. A well mixed feed not only improve your animal performance but also gain you more competitive product in the selling market.

We deeply knowing that you want a safe, effective and reliable mixing process. A high quality animal feed mixer will exactly helps you meet that standard. Whether your feed is for your own use or for sale to others, you will receive a high quality product and build trust with other buyers.

Type & Structure

— Richi Machinery —

There are a series of high performed poultry feed mixer machine can meet different production needs. Our machine can deal with different types of raw material(from powder to granule ) and deliver precise, uniform blending. Discover which mixer can best fit your production line below.

RICHI MACHINERY

Features & Advantages of Using the poultry feed mixer machine

Wide range of raw material compatibility

Our feed mixer series is specially developed for feed manufacturing and is capable of mixing a wide variety of raw materials, such as powders, granules, fibrous materials and small pieces.

Whether for poultry, livestock or aquatic feed, the machines deliver uniform mixing performance. They can also support the addition of liquids like water, oil and molasses. The machine can meet the requirements of diverse feed formulations.

Gentle mixing – protect raw material properties

Our machine ensures gentle and efficient mixing, preserving the integrity and nutritional value of the ingredients. This is very important for sensitive components like vitamins and fiber-rich additives.

The machines help achieve uniform distribution of all materials. In this way, it can efficiently improve feed quality, stability and nutritional consistency.

High efficiency & low consumption

The poultry feed mixer machine delivers fast mixing cycles range form 45 to 60 seconds per batch. They also maintain a low coefficient of variation(basic CV < 7%). This makes perfect uniformity and reliable performance possible.

While making the high output, the machines consume very little power. This identity making them a smart choice for feed producers who want both productivity and energy savings.

Low residue & easy discharge

Our feed mixer series features a user-friendly design which is easy to clean and maintain. This helps keep a clean production environment and improves equipment operating efficiency.

Among them, the double shaft paddle mixer adopts an advanced “machine full length double door” patented technology, ensuring fast and thorough discharge with minimal residue and reduce cross contamination between batches. Our machines incorporate multiple patented technologies to maximize mixing efficiency and minimize labor input.

RICHI MACHINERY

Technical parameters of Our poultry feed mixer machine

The 5 series mixer technical parameters and size chart are as follow:

SLHJ Series Single-Shaft Paddle Mixer Technical Parameters

| Model | SLHJ1A | SLHJ1B | SLHJ2A | SLHJ2B | SLHJ3A | SLHJ4A | SLHJ6A |

| Motor connection | Direct connection | ||||||

| Material | Carbon Steel | Stainless Steel | Carbon Steel | Stainless Steel | Carbon Steel | Carbon Steel | Carbon Steel |

| Power (kw) | 11 | 11 | 22 | 22 | 30 | 37 | 55 |

| Mixing amount per batch (kg/P) | 500 | 500 | 1000 | 1000 | 1500 | 2000 | 3000 |

| Effective volume (m³) | 1 | 1 | 2 | 2 | 3 | 4 | 6 |

SLHSJ Series Double-Shaft Paddle Mixer Technical Parameters

| Model | SLHSJ0.5A | SLHSJ0.5B | SLHSJ1.0A | SLHSJ1.0B | SLHSJ2.0A | SLHSJ4.0A |

| Motor connection | Chain | |||||

| Material | Carbon steel | stainless steel | Carbon steel | stainless steel | Carbon steel | Carbon steel |

| Power (kw) | 5.5 | 5.5 | 7.5 | 7.5 | 18.5 | 30 |

| Mixing amount per batch (kg/P) | 250 | 250 | 500 | 500 | 1000 | 2000 |

| Effective volume (m³) | 0.5 | 0.5 | 1 | 1 | 2 | 4 |

SLHY Series Single-Shaft Double-Ribbon Mixer Technical Parameters

| Model | SLHY0.5A | SLHY1.0A | SLHY1.0A | SLHY2.5L | SLHY3.5L | SLHY5.0L | SLHY7.5L |

| Power (kw) | 4 | 7.5 | 7.5 | 18.5 | 30 | 37 | 45 |

| Mixing amount per batch (kg/P) | 250(manual feeding) | 500 (manual feeding) | 500 (pneumatic feeding) | 1000 (pneumatic feeding) | 1500 (pneumatic feeding) | 2000 (pneumatic feeding) | 3000 (pneumatic feeding) |

| Effective volume (m³) | 0.5 | 1 | 1 | 2.5 | 3.5 | 5 | 7.5 |

STHJ Series Molasses High-Speed Mixer Technical Parameters

| Model | STHJ35x200A/B | STHJ40x250A/B | STHJ50x275A/B |

| Power (kw) | 30 | 37 | 45 |

| capacity(T/H) | 15-20 | 20-25 | 25-30 |

ZGH Series Drum Mixer Technical Parameters

| Model | ZGH-100 | ZGH-200 | ZGH-300 | ZGH-500 |

| Power (kw) | 2.2 | 2.2 | 3 | 3-4 |

| capacity(KG/Batch) | 100 | 200 | 300 | 500 |

Mixer size chart

| 250KG | 500kg | 1000kg | 2000kg | |

| Single Shaft Double Screw Mixer | Manual feeding 2229*752*1448 | Manual feeding 2558*9751448 Pneumatic feeding3074*890*1295 | 3179*2026*1530 | 3980*2828*2103 |

| Double Shaft Paddle Mixer | 1844*1764*1403 | 2353*2018*1680 | 3002*2605*2210 | |

| Double Layer Paddle Type Mixer | 2187*1196*1700 | 2674*1943*1375 | 3291*1733*2319 | 3830*2052*2695 |

If you need help to choose the right mixer, please contact us and tell us your daily output needs, we’ll recommend the best type match to you.

RICHI MACHINERY

Working Principle of the Mixer

The Working Principle of RICHI Mixer

Check more information on our Youtube channel.

Our poultry feed mixer machine typically consist of shell, cover, paddle shaft, discharging mechanism, motor reducer, transmission mechanism and air outlet. The working principle of our mixer is as follow:

First, power on the machine. The motor will drive the main shaft through the reducer, thus the mixing blades will rotate at a set speed. As the blades turn, they lift, scatter and fold the materials in a multi directional flow. This step allows the materials to be thoroughly mixed with a shot cycle time to ensure the consistency of each batch.

It’s worth machine that some models (like the SLHSJ series double shaft paddle mixer) have couples of advanced features. One of the highlighted one is the liquid spray system. It allow precise addition of oil, molasses or other kind of liquid additives during the mixing process thus improves feed quality and enhances nutritional uniformity.

After mixing properly, the machine discharges the material through outlets. For instance, our double shaft paddle mixer which adopt a patented full length double door discharge structure that enables quick and complete unloading. In addition, the built-in air outlet internal pressure and support smooth and stable operation.

RICHI MACHINERY

What to Consider When Buying a poultry feed mixer machine

In order to ensuring high quality feed production and smooth daily operations, choosing a right poultry feed mixer is crucial.

Below are some key points to consider when you’re choosing a fitting operation.

Uniform Mixing Performance

A good mixer must produce a homogeneous mix. Uneven mixing can lead to nutritional imbalance in feed, further affect animal growth and the whole agriculture productivity. Always check the CV of the mixer(the lower, the better).

You also need to check that their product design is sound. For example, does it contain an anti-dead angle design so that the raw materials can be evenly mixed inside the machine.

Durability and Long-Term Performance

A reliable machine should run stably for several years with a minimal performance loss. Good machine material, like the stainless steel, can extend the machine’s service life.

Conversely, poor durability leads to frequent breakdowns and costly repairs.

Gentle Mixing Process

The design of the poultry feed mixer machine should be considered not to crush or damage the materials.

Maintaining the physical integrity of feed can assure its nutritional value remains intact.

Easy Maintenance & Cleaning

Choose user friendly designs that make it easy for workers to clean and maintain the mixer. .

This helps keep the production environment friendly and extent the service life.

Compatibility with Other Equipment

When choosing a feed mixer, it’s not only about the machine itself but also about how well it works within your full production system. A well adapted machine avoids problems such as waste too much manual work or process jams.

In terms of feeding part, the mixer should be able to easily interface with the dosing system and some conveying equipment. On the discharge side, the mixer should be smoothly linked to pelletizers, packers and other lower hand equipment to ensure the consistency of the production process.

Good equipment fit reduces the risk of feed contamination and decreases the likelihood of production interruptions.

After-Sales Support

Always select a former manufacturer that offers strong customer service.

Timely support can reduce downtime and protect your operations.

Application in the Production Line

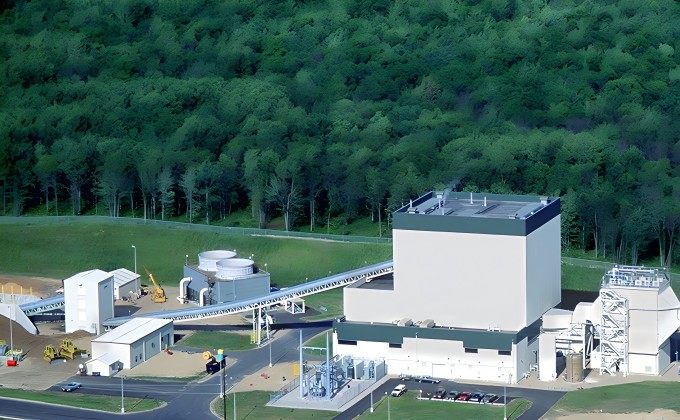

Poultry feed mixer machine play a central role in modern animal feed pellet plant. After the ingredients have been weighed and milled, they must be thoroughly mixed to ensure that each batch of feed provides consistent nutrition. Our range of mixers is the equipment that takes care of this crucial part of the process.

In a complete animal feed processing plant, the mixer is usually located after the batching section and before the pelletizing section. It takes powdered ingredients such as corn, wheat bran, rice bran and various additives(like the premix of vitamins) and mixes them into a uniform compound. Some models also support the addition of liquids such as molasses and vegetable, fish oil during the mixing process to enhance the palatability of the feed or to adjust the nutrient content.

A well-designed mixer not only enhances the mixing quality, but also significantly improves the operational efficiency of the whole production line. A well-mixed feed helps the subsequent pelleting process to run smoothly, ensures consistent quality of the finished product, and improves the performance of the animals. Our mixers can be easily connected to elevators, silos, feed hammer mills, pelletizers and packaging systems to form an automated and efficient integrated production line.