Poultry Feed Making Machine Price

Poultry feed making machine price ranges from USD 10,000 to 2,800,000, depending on production capacity, machine model, and functional configuration.

Entry-level machines for small-scale poultry farms are more affordable and focus on basic pelletizing needs, while larger, high-output machines come with advanced automation, stronger power systems, and improved durability, resulting in higher overall costs. Choosing the right machine depends on your production scale, feed formulation requirements, and budget plan.

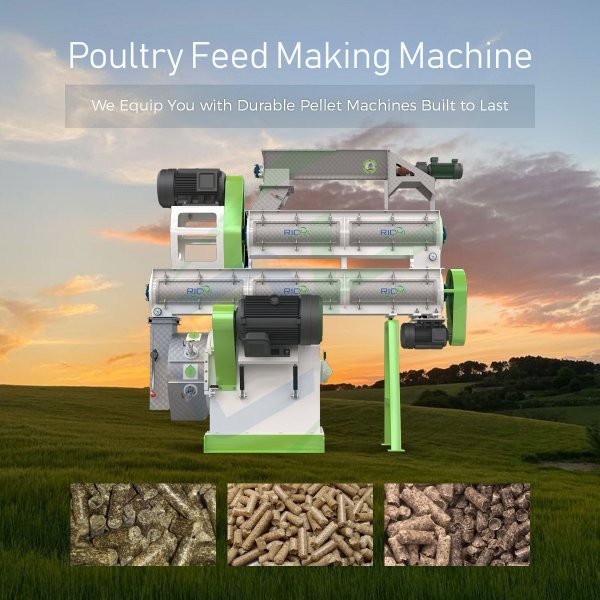

What Is The Poultry Feed Making Machine?

The poultry feed making machine is a complete set of equipment designed to produce high-quality, uniform poultry feed pellets. It can process a wide variety of raw materials, including corn, soybean meal, wheat bran, rice husks, and other agricultural by-products, transforming them into compact, nutritious, and easy-to-digest feed for chickens, ducks, and other poultry.

These machines are suitable for medium to large farms and feed mills of various capacities. Built with durable materials, energy-efficient motors, and user-friendly controls, the equipment is designed for reliable operation, low maintenance, and long service life.

The poultry feed making machine price depends on factors such as production capacity, model, configuration, and optional accessories. Mini poultry feed machine price for limited-scale production are more budget-friendly, while large-scale, high-capacity systems with advanced automation and additional equipment naturally cost more.

Investing in the poultry feed making machine can significantly improve farm productivity, reduce feed waste, and lower feeding costs. By producing consistent, high-quality pellets, farmers can ensure their poultry receives balanced nutrition, supporting healthier growth and better overall performance. When assessing the price, it is important to consider not only the initial cost but also the machine’s efficiency, durability, and long-term operational benefits.

Video Showcase Of Poultry Feed Making Machine

Watch our poultry feed machine in action and see how it handles the full production process, from raw material crushing and mixing to pelletizing, cooling, and packaging. These videos demonstrate the machine’s reliable performance and operational efficiency, showing that the price of poultry feed making machine is well matched to its capabilities and production capacity.

Different Poultry Feed Making Machine Price In Production Line

The poultry feed making machine price varies depending on the machine’s role in the production line, its capacity, and level of automation. From small-scale pellet mills to complete feed production systems, each machine is designed to match its performance, durability, and production value. Understanding these differences helps farms choose the right equipment to optimize feed quality and efficiency.

Vibrating Screen

Vibrating Screen Price: 2,000-10,000 USD

How To Produce Poultry Feed Pellets?

Producing high-quality poultry feed pellets requires a systematic process that ensures uniform nutrition, easy digestion, and optimal pellet formation. The production involves multiple stages, each designed to improve feed quality and operational efficiency.

The configuration of the production line is closely related to the poultry feed making machine price, as factors such as production capacity, automation level, and optional auxiliary equipment directly affect the total investment. A well-matched equipment setup not only improves feed quality and operational efficiency but also helps optimize costs and ensure stable, long-term production.

Raw Material Crushing

01

Use a hammer mill to reduce raw materials into fine particles, improving mix uniformity and pellet quality.

Batching And Mixing

02

Combine different raw materials and additives evenly in a feed mixer to achieve balanced nutrition.

Pelletizing Section

03

Feed the mixed materials into a pellet machine to form uniform, compact feed pellets of the desired size.

Cooling Section

04

Reduce the temperature and moisture of the freshly pelleted feed using a cooler to maintain shape and extend shelf life.

Screening Section

05

Remove broken pellets and oversized particles to ensure consistent pellet size.

Packing Section

06

Pack the finished feed pellets into bags or bulk containers for storage, transport, and sale.

Different Global Cases With Different Poultry Feed Making Machine Price

The poultry feed making machine price varies around the world due to differences in production capacity, automation level, and equipment configuration. With over 30 years of industry experience, RICHI Machinery has successfully delivered pellet machines and related pellet equipment products to more than 140 countries and regions. By examining various global cases, it becomes clear how different machines are selected to meet local farm sizes, feed types, and production goals. These examples highlight the relationship between price, performance, and the specific needs of poultry farms in different countries, providing useful insights for anyone planning to invest in feed production equipment.

Poultry Feed Making Machine For Sale Tanzania

- Production Capacity: 2T/H

- Project Country: Tanzania

- Estimated Price: 12,000 USD

- Raw Material: Corn, soybean meal, wheat bran, rice husks.

- Project Background: A medium-scale poultry farm in Tanzania needed a complete animal feed pellet production line to produce high-quality pellets and reduce feed costs. The farm required a compact, easy-to-operate system suitable for limited space and manpower.

- Client Feedback: “The line is compact but efficient. It’s easy for our team to operate, and the pellets are consistent and well-formed.”

Poultry Feed Production Line For Sale Angola

- Production Capacity: 3-4T/H

- Project Country: Angola

- Estimated Price: 50,000 USD

- Raw Material: Corn, soybean meal, rice husks, wheat bran, fish meal.

- Project Background: A medium-scale feed mill in Angola wanted to upgrade to a full chicken feed production line to improve feed consistency and output. The client required stable operation and moderate automation across the entire line.

- Client Feedback: “We are very satisfied with the performance. The feed pellets are uniform, and the production process runs smoothly without frequent interruptions.”

Poultry Feed Making Plant In Uzbekistan

- Production Capacity: 5T/H

- Project Country: Uzbekistan

- Estimated Price: 75,000 USD

- Raw Material: Corn, soybean meal, wheat bran, sunflower meal.

- Project Background: A commercial animal feed mill plant for in Uzbekistan required a medium-capacity poultry feed production line to ensure reliable operation, high pellet quality, and minimal maintenance.

- Client Feedback: “The machines are reliable and easy to maintain. Our team learned to operate them quickly, and the overall production efficiency has improved.”

Poultry Feed Machine For Sale Afghanistan

- Production Capacity: 10T/H

- Project Country: Afghanistan

- Estimated Price: 180,000 USD

- Raw Material: Corn, soybean meal, wheat bran, rice husks, vitamins & minerals.

- Project Background: A large poultry feed pellet plant in Afghanistan wanted a high-capacity feed production line capable of producing pellets meeting nutritional standards for various poultry types. Partial automation was required for improved efficiency.

- Client Feedback: “The production line meets our requirements perfectly. The pellets are high quality, and the system is stable even during long operation hours.”

Poultry Feed Making Machine In Saudi Arabia

- Production Capacity: 20T/H

- Project Country: Saudi Arabia

- Estimated Price: 285,000 USD

- Raw Material: Corn, soybean meal, wheat bran, rice husks, alfalfa meal.

- Project Background: A commercial animal feed production line in Saudi Arabia wanted to modernize with a fully automated, high-capacity production line to meet growing demand.

- Client Feedback: “The fully automated system has reduced manual work significantly. Operation is smooth, and feed output meets our commercial standards consistently.”

Compound Feed Pellet Production Line In Algeria

- Production Capacity: 30T/H

- Project Country: Algeria

- Estimated Price: 500,000 USD

- Raw Material: Corn, soybean meal, wheat bran, rice husks, sunflower meal, fish meal.

- Project Background: A large-scale compound animal feed processing plant in Algeria required a high-capacity, fully automated line to produce consistent, nutritious pellets for commercial poultry and livestock farms.

- Client Feedback: “The equipment runs efficiently and reliably. The team is impressed by the durability and consistency of the feed pellets produced by the line.”

Key Technical Characteristics Of Poultry Feed Making Machine

Understanding the technical features of a poultry feed making machine is essential for selecting the right equipment for your farm or feed production line. These machines are designed to efficiently process a variety of raw materials into uniform, high-quality feed pellets while minimizing energy consumption and labor. When considering poultry feed making machine price, factors such as capacity, energy efficiency, and equipment configuration are important indicators of overall value.

How to Choose the Right Machine?

Selecting the right poultry feed making machine is critical for achieving efficient production and high-quality feed. Factors such as production capacity, raw material types, automation level, and available space should all be considered. Additionally, the poultry feed making machine price should be evaluated in relation to the machine’s features, performance, and long-term operational benefits. Choosing the right system ensures that your farm or feed mill operates efficiently, reduces waste, and consistently produces nutritious feed for poultry.

Match Capacity to Needs

Evaluate your farm size or feed production requirements carefully. Choosing a machine that is too small can limit production and cause frequent overload, while a machine that is too large may result in unnecessary investment and higher operational costs. A properly sized system ensures smooth production, optimal efficiency, and long-term cost-effectiveness.

Check Raw Material Compatibility

Make sure the equipment can process all the raw materials you plan to use, such as corn, soybean meal, wheat bran, rice husks, or other additives. Some machines are more versatile and can handle a variety of ingredients without affecting pellet quality. Ensuring compatibility helps maintain consistent feed quality and reduces maintenance issues caused by improper material handling.

Consider Performance and Support

Assess the machine’s durability, energy efficiency, ease of operation, and availability of after-sales support. The poultry feed making machine price should reflect these factors to ensure a worthwhile investment. A well-selected machine will save labor, reduce downtime, and provide consistent, high-quality pellets for your poultry.

Why Choose Our Poultry Feed Making Machine?

Choosing the right poultry feed making machine is essential for ensuring stable production, consistent feed quality, and long-term operational efficiency. Our solutions are designed to meet the needs of medium to large farms as well as feed mills of various capacities, combining reliable performance with practical design. The following advantages explain why our equipment is trusted by customers worldwide.

High-Quality Equipment

Our poultry feed making machines are manufactured using durable materials and precision-engineered components. The complete production line is designed for stable operation, efficient processing, and consistent pellet quality, ensuring reliable performance even during continuous operation.

Customized Solutions

We provide flexible animal feed pellet machine for sale based on different production capacities, raw materials, and plant layouts. Each poultry feed production line can be optimized to match specific project requirements, helping customers achieve efficient production while maintaining stable feed quality.

Extensive Experience

With projects in over 140 countries and regions worldwide, RICHI has extensive experience in poultry feed pellet production. RICHI Machinery turnkey service ensures professional guidance and reliable support for clients of all scales.

FAQ

Understanding the poultry feed making machine price is an important step when planning a feed production project. Buyers often have questions about equipment configuration, production capacity, operating costs, and long-term performance. The following frequently asked questions are designed to clarify common concerns and help you better evaluate different poultry feed production solutions.

How much does the poultry feed making machine cost?

+

A complete poultry feed making machine line generally costs between USD 10,000 and USD 2,800,000. The final price depends on production capacity, automation level, equipment configuration, and plant layout. Complete lines usually include crushing, mixing, pelletizing, cooling, conveying, and sometimes packing systems.

If your production requirements are relatively low and your raw materials already meet pelletizing conditions, you can choose to purchase only a poultry feed pellet machine. This option is suitable for farms or small feed producers that do not require crushing or mixing systems and want a more economical investment.

Can the poultry feed making machine process different raw materials and produce feed for different animals?

+

Yes. Our poultry feed making machine and complete feed production line can process a wide variety of raw materials, including corn, soybean meal, wheat bran, rice husks, and other grains or agricultural by-products. A single production line can produce feed for different animals, such as chickens, ducks, geese, or even fish, as long as you adjust the raw material ratios and pellet size according to the nutritional requirements of each species.

When considering poultry feed making machine price, note that machines with higher flexibility for multiple feed types or raw materials may have a slightly higher cost, but they provide excellent value by allowing one line to handle various feed formulations efficiently. Switching between feed types usually requires changing the pellet die and adjusting the mixer formula, making a single production line highly versatile and suitable for farms producing multiple types of feed.

Are there hidden costs to consider besides the machine price?

+

Yes, besides the poultry feed making machine price, there are several additional costs that should be considered when planning a feed production project. These may include installation and commissioning, transportation and logistics, electrical wiring, civil works, and operator training.

Operating costs such as electricity consumption, routine maintenance, spare parts, and raw material preparation should also be taken into account. Evaluating these factors in advance helps ensure a more accurate budget and smoother project execution.

How to Choose the Right Machine and Price for a Farm with 100,000 Chickens and 20,000 Ducks?

+

For a large-scale poultry farm raising 100,000 chickens and 20,000 ducks, selecting the right poultry feed making machine starts with calculating daily feed demand. On average, one chicken consumes about 120 g of feed per day, while one duck consumes around 150 g per day.

Daily feed consumption calculation:

- Chickens: 100,000 × 120 g = 12,000 kg/day

- Ducks: 20,000 × 150 g = 3,000 kg/day

- Total feed demand: 15,000 kg/day

If the feed production line operates 6 hours per day, the required hourly output is: 15,000 kg ÷ 6 h = 2,500 kg/h. Based on this requirement, a 2.5 T/H poultry feed production line is recommended for stable and efficient production.

If raw materials are already crushed and mixed, a pellet machine with matching capacity may be sufficient. The poultry feed pellet machine price is approximately USD 10,000-20,000. For fully integrated production, a complete line including crushing, mixing, pelletizing, cooling, and conveying systems is more suitable. The complete poultry feed making machine price is approximately USD 50,000-120,000.