Pellet Mill Malaysia

High quality pellet mill for sale Malaysia & Customized pellet mill Malaysia solutions

Introduction to Pellet Mill Malaysia

The pellet mill Malaysia market has been experiencing rapid growth in recent years, particularly in the biomass energy sector. Each year, over 20 million tons of forestry waste are generated, providing a vast array of raw materials for pellet mill applications. This abundance of resources has significantly increased the production of biomass fuel pellets. As a result, the Malaysian industry is seeking high-efficiency and stable pellet mill solutions.

A pellet mill is a piece of equipment that transforms powdered materials into small, dense pellets. It is widely used in the production of animal feed, biomass fuel, and pet litter. With the advanced pelletizing techniques adopted by local industries, the pellet mill has become essential for achieving sustainable development and maximizing the use of local resources.

Thanks to government policies promoting energy transition, the demand for biomass fuel pellets continues to grow, making it a core component of clean energy. Additionally, the stable development of agriculture and aquaculture has increased the need for animal feed pellets. Furthermore, the rise of the pet industry has boosted the market for pet-related pellet production.

The diverse applications of pellet mills indicate a broad range of development opportunities in the Malaysian market. Alongside this, the rich resource availability and varying requirements present pellet manufacturers with substantial opportunities. Let’s take a closer look at some successful projects implemented by RICHI in Malaysia.

Pellet Mill Malaysia Projects

To better understand the real-world application of pellet mill Malaysia solutions, let’s look at some successful local projects.

3 – 5

Production (ton/hour)

3 – 5

Pellet size (mm)

3-5 T/H Animal Mash Feed Pellet Mill Malaysia Project

- Project Location: Malaysia

- Project Name: Animal Mash Feed Production Line

- Application: Livestock feed manufacturing (mash feed)

- Production Capacity: 3-5 tons per hour

- Finished Pellet Size: 3.0–5.0 mm

- Raw Materials: Corn, soybean meal, oil, premix

- Main Equipment Configuration: Pre-cleaner, hammer mill, pellet mill, mixer

- Process Flow: Crushing → Mixing → Pelletizing → Cooling → Screening

Project Background

The client operates a medium-sized livestock farm in Malaysia and needed a feed solution to produce high-quality animal mash. Using local raw materials like corn and soybean meal, they wanted a production line capable of processing both coarse mash (3–8 mm) and fine powder (down to 0.5 mm).

As a typical user of pellet machine Malaysia systems, the client had two key requirements: the equipment height must be under 6.5 meters due to factory constraints, and the line must include a pre-cleaning section to deal with unprocessed raw materials. RICHI delivered a compact, efficient solution tailored to meet these needs without sacrificing performance.

Installation & Operation Detail

- Project Start Time: March 7, 2022

- Installation Period: 30 days

- RICHI On-Site Engineers: 2 installation engineers provided full support

- Factory Layout: Custom equipment arrangement within 8m × 12m × 8m

- Occupied Space by RICHI Equipment: 8m (L) × 12m (W) × 8m (H)

- Total Power Consumption: Approximately 50 kWh

- Labor Requirement: 4–5 workers for operation

Tailored Solution by RICHI

To meet the client’s specific challenges, RICHI provided the following custom services:

01 Layout Design

- Workshop layout drawing

- Equipment layout drawing

- Steel structure list

- Installation drawings for both steel structures and equipment

02 Design Adjustments

- Customized hammer mill output to achieve 0.5mm powder size

- Full process without boiler involvement

- Layout height limited to 6.5m to fit client factory structure

This case reflects the adaptability and engineering precision required for pellet machine Malaysia projects, particularly when dealing with spatial constraints and demanding process requirements.

Why It Matters

This 3-5 T/H animal mash feed pellet mill Malaysia project exemplifies how RICHI Machinery can adapt standard feed production systems to meet client-specific needs in layout, particle size, and material conditions.

With durable equipment, thoughtful design, and hands-on support, we continue to deliver smart feed solutions across Southeast Asia.

1

Production (ton/hour)

2 – 4

Pellet size (mm)

1 T/H Tofu Cat Litter Pellet Mill Malaysia Project

- Location: Klang Valley, Malaysia

- Project Name: 1 T/H Tofu Cat Litter Production Line

- Raw Materials: Okara (tofu residue), guar gum, calcium carbonate, starch, and blended additives

- Final Pellet Size: 2 mm and 4 mm

- Factory Size: 12m × 15m × 8m

- Power Demand: 60 kW

- Manpower: 2 operators per shift

- Installation Time: 15 days

- Start Date: April 15, 2023

- On-site Support: 3 RICHI engineers

- Main Equipment: Screw conveyor, mixer, storage bin, cat litter pellet machine, cooler, buffer hopper, automatic packing machine

Project Background

With the growing demand for plant-based, biodegradable cat litter in Southeast Asia, a Malaysian pet products company decided to set up a dedicated tofu cat litter production facility. The client had access to abundant tofu residue (okara) from local food manufacturers and aimed to transform this low-value by-product into high-quality litter for both domestic sales and export.

The project site was chosen in Klang Valley for its industrial infrastructure and convenient logistics for export. The goal was to build a compact, efficient, and export-ready production line capable of stable 1T/H output with minimal labor.

Production Process

- Material feeding and mixing, with dust-tight screw conveyors and a horizontal mixer

- Pelletizing via the customized MZLH420 pellet machine

- Cooling and screening to ensure pellet stability and uniformity

- Buffer hopper & automatic packing to streamline product bagging and reduce dust

Tailored Solution by RICHI

RICHI solution was fully customized to fit the client’s materials, site constraints, and market goals:

01 Compact Design

Smart equipment layout allowed the entire line to fit into a small workshop without compromising performance.

02 Custom Pellet Die

Supported dual sizes (2mm and 4mm) for different cat litter styles.

03 Buffer Hopper Integration

Balanced the cooling and packing processes, ensuring stable flow and efficient packaging.

04 Pre Pelleting Storage Bin

Maintained continuous pelletizer operation even when mixing cycles fluctuated.

05 Stainless Steel Contact Parts

Ensured hygiene and corrosion resistance for export-grade production.

Why It Matters

This cat litter pellet mill Malaysia project demonstrates how even small-scale manufacturers can successfully enter the high-value pet care market with the right technology and support. By turning okara waste into eco-friendly cat litter, the client reduced raw material costs and created a scalable, sustainable business.

With RICHI tailored design and hands-on installation support, the client now operates one of the region’s most efficient small-scale tofu cat litter lines—and is already planning to expand.

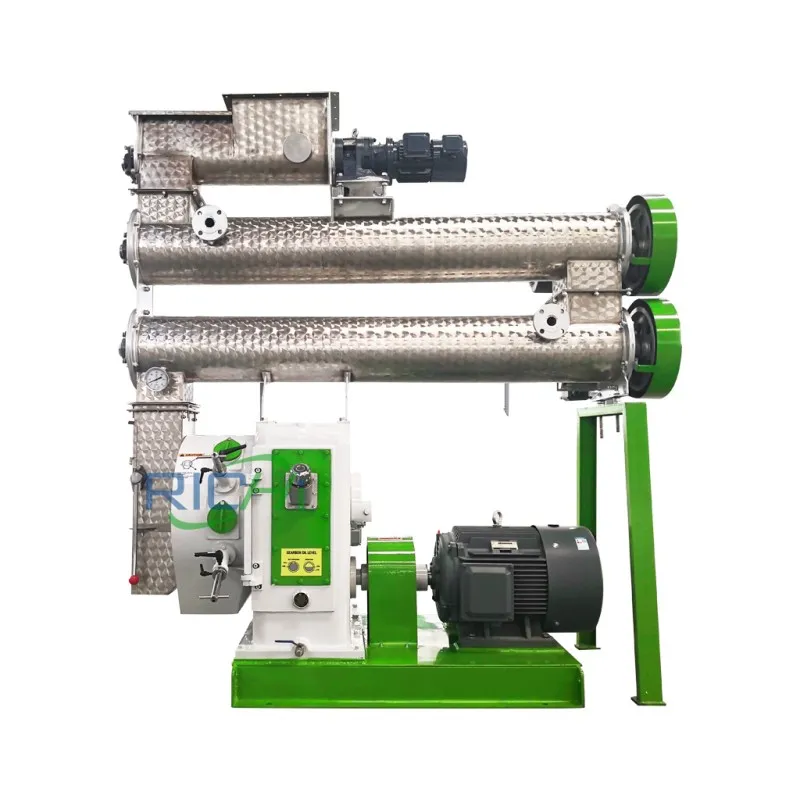

4-5 T/H Sinking Fish Feed Pellet Mill Malaysia Project

- Project Location: Malaysia

- Project Name: Sinking Fish Feed Mill Plant

- Application: Aquaculture feed (sinking fish pellets)

- Production Capacity: 4-5 tons per hour

- Finished Pellet Size: 2.0–4.0 mm

- Raw Materials: Corn, soybean meal, wheat bran, fish meal, rice bran, premix

- Main Equipment Configuration: Pre-cleaner, hammer mill, micro pulverizer, mixer, triple-layer conditioner fish feed pellet machine, cooler, screener, automatic packing machine

- Process Flow: Receiving → Crushing → Batching & Mixing → Micro Crushing → Secondary Mixing → Pelletizing → Cooling → Screening → Packing

4 – 5

Production (ton/hour)

2 – 4

Pellet size (mm)

Project Background

The Malaysian client is an established aquatic feed manufacturer aiming to enhance production efficiency and pellet quality. Their existing production line could not meet growing demand, especially in terms of water stability and feed utilization for species like tilapia and catfish.

The client emphasized two major requirements

- Use of a pellet mill with triple-layer conditioner to improve pellet durability and digestibility.

- Incorporation of a micro crushing process to achieve finer particle sizes before pelletizing. Thus allows smoother pellet surface and improved nutrient absorption.

Additionally, they required high automation and strict quality control.

Installation & Operation Detail

- Project Start Time: April 2, 2024

- Installation Period: 35 days

- RICHI On-Site Engineers: 2 senior engineers for on-site installation and commissioning

- Factory Layout: Customized within a 12m × 9m × 8m space

- Occupied Space by RICHI Equipment: 12m (L) × 9m (W) × 8m (H)

- Total Power Consumption: Approx. 120 kWh

- Labor Requirement: 5–6 workers per shift

Tailored Solution by RICHI

To fulfill the client’s needs for water-stable, slow-sinking, nutrient-rich pellets, RICHI designed a high-efficiency sinking fish feed plant with the following customizations:

01 Layout Design

- 3D workshop and equipment layout drawing

- Detailed piping, cable, and foundation drawings

- Material flow diagram optimized for micro crushing and dual mixing

02 Material Adaptation

- Custom feed formula compatibility for both freshwater and brackish water fish

- Modular setup allows future expansion or feed type switching

Why It Matters

This 5 T/H sinking fish feed pellet mill Malaysia project in showcases RICHI Machinery’s ability to deliver specialized aquafeed solutions through advanced engineering and process refinement.

With the integration of a triple-conditioner system, the client now produces high-quality, durable sinking pellets. For meeting both nutritional and physical performance standards.

2 – 3

Production (ton/hour)

6 – 8

Pellet size (mm)

2–3 T/H Palm Waste Pellet Mill Malaysia Project

- Project Location: Malaysia

- Project Name: Palm Waste Biomass Pellet Production Line

- Application: Biomass energy pellet production

- Production Capacity: 2–3 tons per hour

- Finished Pellet Size: 6 mm – 8 mm

- Raw Materials: Palm kernel husks, palm fibers, empty fruit bunch residues

- Main Equipment Configuration: Crusher, dryer, pellet mill, cooler, packing machine

- Process Flow: Crushing → Drying → Pelletizing → Cooling → Packing

Project Background

Malaysia’s palm oil industry creates tons of biomass waste every year. Instead of just throwing this stuff away, a palm oil manufacturer decided to turn palm residues into commercial biomass fuel using a customized wood pellet machine Malaysia solution. This not only makes better use of waste but also lets them cash in on pellet exports.

Before everything was delivered, RICHI technicians put the whole machine through rigorous testing to ensure it ran smoothly and produced high-quality pellets. Validating its performance as a representative wood pellet machine Malaysia system This really helped cut down the time needed for getting everything up and running on-site.

Installation & Operation Detail

- Project Start Time: April 2025

- Installation Period: 30 days

- RICHI On-Site Engineers: 2 engineers for mechanical setup and process tuning

- Factory Layout: Tailored for linear flow, dust control, and maintenance convenience

- Occupied Space by Equipment: 12m (L) × 15m (W) × 6.5m (H)

- Total Power Consumption: 60 kWh

- Labor Requirement: 4–5 operators per shift

Tailored Solution by RICHI

01 Adapted to Fibrous Palm Waste

This project is a benchmark case for processing difficult biomass like palm kernel shells and EFB fibers. RICHI provided a heavy-duty crusher specifically engineered to handle long, lightweight fiber materials without clogging or excessive wear.

02 Flexible Pellet Output

Equipped with a pellet mill supporting interchangeable dies, the line can produce pellets of different diameters (6/8 mm), allowing the client to serve diverse market demands—from local boiler use to overseas industrial heating supply.

03 Compact & Efficient Layout

Given the constraints of the client’s existing factory space, all machines were arranged to ensure efficient material flow while keeping installation and future maintenance access simple and clear.

04 Energy-Efficient Operation

By optimizing motor configuration and reducing unnecessary transitions, the entire line runs stably with relatively low power consumption per ton, making the operation cost-effective even at medium scale.

05 Custom Engineering Support

RICHI provided full sets of engineering drawings: production layout, installation guide, steel structure list, and operational planning—ensuring the client could prepare in advance and avoid downtime during setup.

Client Perspective

“We didn’t expect a pellet line to handle palm fibers this smoothly. RICHI’s team helped us turn waste into value with a line that fits exactly into our existing plant without rebuilding. The pellets are dense, burn well, and meet our local distributor’s quality standards.”

1 – 2

Production (ton/hour)

4 – 8

Pellet size (mm)

1-2 T/H Goat Feed Pellet Mill Malaysia Project

- Project Location: Malaysia

- Project Name: Goat Feed Pellet Production Line

- Application: Ruminant feed manufacturing (goat pellet feed)

- Production Capacity: 1–2 tons per hour

- Finished Pellet Size: 4.0–8.0 mm

- Raw Materials: Corn, wheat bran, soybean meal, hay powder, premix

- Main Equipment Configuration: Pre-cleaner, hammer mill, mixer, goat feed pellet making machine with automatic feeder & storage bin, cooler, packing machine

- Process Flow: Crushing & Mixing → Pelleting → Cooling → Packing

Project Background

This project was initiated by a family-owned goat farming business in Malaysia that needed to upgrade their feed preparation system. As goats are ruminants with unique digestive systems, their feed requires a formulation high in fiber and moderate in energy. To meet these nutritional requirements, the client primarily used hay powder, bran, and grain-based raw materials.

Due to limited labor and the need for continuous operation, the client emphasized the importance of automation. To solve this, RICHI equipped the pellet mill with a 1m³ storage bin made of 3mm thick steel. This bin acts as an automatic feeding buffer between the mixer and pellet machine, allowing uninterrupted production and maintaining stable pellet output.

The equipment layout was also customized to fit into their existing workshop with a strict height limitation of 6.5 meters.

Installation & Operation Detail

- Project Start Time: October 2024

- Installation Period: 28 days

- RICHI On-Site Engineers: 2 engineers dispatched for installation and training

- Occupied Space by RICHI Equipment: 7.5m (L) × 10.5m (W) × 8m (H)

- Total Power Consumption: 35 kWh

- Labor Requirement: 3–4 worker

Tailored Solution by RICHI

01 Design & Layout

- Workshop layout drawing

- Equipment layout drawing

- Steel structure list

- Installation diagrams for machinery and structure

02 Functional Customization

- 1m³ storage bin for mixed materials to ensure continuous pelletizing

- Automatic feeding system integrated with pellet mill

- Special hammer mill setup to process fibrous hay materials effectively

03 Workshop Compatibility

- All equipment height limited to 6.5 meters

- Compact layout suitable for small to medium-sized farms

- Boiler-free energy-saving process

This case reflects the adaptability and engineering precision required for pellet machine Malaysia projects, particularly when dealing with spatial constraints and demanding process requirements.

Why It Matters

This 1–2 T/H goat feed pellet mill Malaysia project highlights how RICHI Machinery adapts its standard feed equipment to serve small and medium-sized ruminant farmers. From accommodating fibrous feedstocks to implementing automation with a storage bin and automatic feeder, the design ensures higher efficiency and consistency.

This project is a practical model for modern, semi-automated goat feed production in Southeast Asia.

Pellet Mill Malaysia Market Outlook

Malaysia has a lot of agricultural waste, like palm kernel shells, empty fruit bunches, wood chips, and sawdust. It gives a great boost to the pellet mill Malaysia market, especially in the biomass sector.

These biomass pellets are a clean and eco-friendly alternative fuel that’s becoming super popular in power plants and industrial boilers. It further highlighting the importance of pellet mill Malaysia in supporting the country’s renewable energy and green development goals. Thanks to supportive government policies and plenty of raw materials. The biomass pellet machine market has been growing really fast in recent years.

On top of that, pellet machines in Malaysia are branching out into different uses, especially in industries like livestock feed, aquafeed, and pet products:

Animal feed pellet machines are essential for the local livestock scene, taking care of the daily feed needs for pigs, cattle, chickens, and more. Aquafeed pellet machines are all about making sinking feed for fish, which fits nicely with the push for larger and more efficient fish farming. Plus, pet pellet machines are tapping into the booming pet economy, helping produce everything from cat litter to pet food.

All these different applications open up exciting growth opportunities for pellet machine equipment in Malaysia.

What’s really interesting is that as the aquaculture industry keeps growing and getting more tech-savvy, the demand for sinking fish feed is on the rise too.

With more large-scale farming of popular fish like tilapia and catfish, there’s a big need for high-quality sinking feed. Thus driving innovation and growth in the market for related pellet machine equipment.

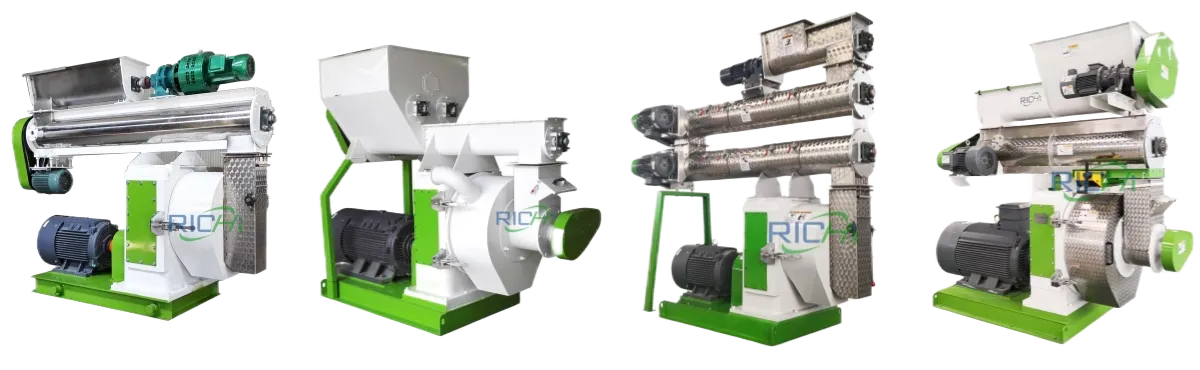

Types of Pellet Mills We Offer in Malaysia

Here at RICHI Machinery, we offer multiple specialized types of pellet mills to meet the diverse needs of our Malaysia clients. Whether you’re producing animal feed, biomass fuel, or plant-based cat litter. You can check more animal feed pellet machine for sale model on our youtube channel.

1. Animal Feed Pellet Mill Malaysia

RICHI MACHINERY

Generally used to make animal feed pellets. We also support customized pellet making machine.

SZLH250 Feed Pellet Mill

- Capacity: 1.0-1.5 tons/hour

- Main Power: 15–22 kW

- Application: Poultry (chicken, layer, broiler), rabbit, goat

- Finished Pellet Size: 2-12mm

SZLH320 Feed Pellet Mill

- Capacity: 3-4 tons/hour

- Main Power: 22–37 kW

- Application: Poultry, pigs, rabbits, goats

- Finished Pellet Size: 2-12mm

SZLH420 Feed Pellet Mill

- Capacity: 10-12 tons/hour

- Main Power: 55-110 kW

- Application: Cattle, pigs, poultry, livestock

- Finished Pellet Size: 2-12mm

SZLH508 Feed Pellet Mill

- Capacity: 15-16 tons/hour

- Main Power: 110-160 kW

- Application: Poultry, cattle, pigs, large livestock farms

- Finished Pellet Size: 2-12mm

SZLH678 Feed Pellet Mill

- Capacity: 30–33 tons/hour

- Main Power: 250 kW

- Application: Poultry, cattle, pigs, large livestock farms

- Finished Pellet Size: 2–12 mm

MZLH320 Biomass Pellet Mill

- Capacity: 0.2-0.3 tons/hour

- Main Power: 15–22 kW

- Application: Straw, grass, alfalfa, cat litter

- Pellet Size: 4-12 mm.

MZLH350 Biomass Pellet Mill

- Capacity: 0.3-0.5 tons/hour

- Main Power: 22–37 kW

- Application: Straw, grass, alfalfa, cat litter

- Pellet Size: 4-12 mm

2. Biomass Pellet Mill Malaysia

RICHI MACHINERY

Function is used to produce biomass combustion pellets. RICHI support customized pellet mill equipment. Tell us your output and needs to get the most suitable equipment for you.

MZLH420 Biomass Pellet Mill

- Capacity: 1-1.2 tons/hour

- Main Power: 37–90 kW

- Application: Straw, wood sawdust, alfalfa

- Pellet Size: 4-12 mm

MZLH520 Biomass Pellet Mill

- Capacity: 1.5-2 tons/hour

- Main Power: 90-132 kW

- Application: Wood chips, straw, cat litter

- Pellet Size: 4-12 mm

MZLH678 Biomass Pellet Mill

- Capacity: 2.5–3 tons/hour

- Main Power: 132-185 kW

- Application: Wood chips, straw, cat litter

- Pellet Size: 4–12 mm

3. Cat Litter Pellet Mill Malaysia

RICHI MACHINERY

With models ranging from 0.5 to 8 tons per hour, they meet the needs of small factory to large-scale industrial production.

MSZLH250 Cat Litter Pellet Machine

- Capacity: 1.0–1.5 tons/hour

- Main Power: 22 kW

- Feeder Power: 1.1 kW

- Conditioner Power: 1.5 kW

- Ring Die Diameter: 250 mm

- Pellet Size: 2–12 mm

- Application: Ideal for entry-level cat litter manufacturers or small-scale plants using tofu residue and natural additives to produce eco-friendly pellets.

MSZLH320 Cat Litter Pellet Machine

- Capacity: 3.0–4.0 tons/hour

- Main Power: 37 kW

- Feeder Power: 1.5 kW

- Conditioner Power: 4.0 kW

- Ring Die Diameter: 320 mm

- Pellet Size: 2–12 mm

- Application: Suitable for medium-sized tofu cat litter production lines requiring stable output and consistent pellet quality.

MSZLH350 Cat Litter Pellet Machine

- Capacity: 5.0–6.0 tons/hour

- Main Power: 55 kW

- Feeder Power: 1.5 kW

- Conditioner Power: 4.0 kW

- Ring Die Diameter: 350 mm

- Pellet Size: 2–12 mm

- Application: Designed for growing manufacturers seeking high efficiency and low powder rate in tofu-based cat litter pelletizing.

MSZLH420 Cat Litter Pellet Machine

- Capacity: 10.0–12.0 tons/hour

- Main Power: 110 kW

- Feeder Power: 1.5 kW

- Conditioner Power: 7.5 kW

- Ring Die Diameter: 420 mm

- Pellet Size: 2–12 mm

- Application: A core machine for industrial tofu cat litter production lines with robust performance and long-term reliability.

MSZLH508 Cat Litter Pellet Machine

- Capacity: 15.0–16.0 tons/hour

- Main Power: 160 kW

- Feeder Power: 1.5 kW

- Conditioner Power: 7.5 kW

- Ring Die Diameter: 508 mm

- Pellet Size: 2–12 mm

- Application: Best suited for high-capacity production facilities focusing on export-grade cat litter with tight quality control.