Pellet Making Machine South Africa

High quality pellet mill for sale South Africa & Customized pellet making machine South Africa solutions

Brief introduction of Pellet Making Machine For Sale South Africa

Pellet making machine is a multifunctional equipment that can press variety of materials such as straw, wood, forage and corns into dense and uniform pellet. It is widely used in animal feed, biomass fuel and wood processing. With the rapid growth in demand for efficient pelletizing equipment in various industries, the pellet making machine South Africa market continues to expand.

In recent years, South Africa has introduced progressive policies such as the Climate Change Act of 2024 and the Integrated Resource Plan (IRP) 2019. Thus promote renewable energy and sustainable resource utilization. In this way boost the market demand for biomass pellet mills.

Meanwhile, the rapid development of livestock and agricultural sectors has also driven the demand for reliable animal feed pellet mills and so on. This expands the application space of diversified pellet mills.

As a global leader in pelletizing technology, RICHI Machinery is steadily expanding its presence in South Africa. We provides customized pellet mill for sale South Africa that meet local raw material and industry requirements. With growing demand in animal feed, biomass and wood pellets, the pellet production industry in South Africa shows great growth potential.

South Africa Pellet Mill Projects

Based on the diverse pellet mill market in South Africa, there are many success stories demonstrating the advantages of RICHI pellet making machine. Below are some of the typical pellet making machine South Africa projects.

2 – 2.5

Production (ton/hour)

3 – 5

Pellet size (mm)

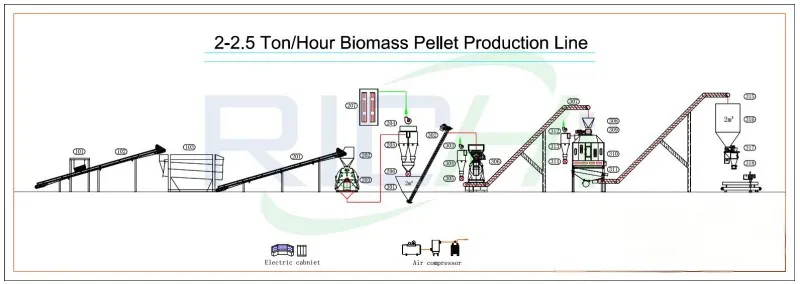

1. Wheat Straw Pellet Making Machine South Africa Project

- Project Location: South Africa

- Project Name: 3–5mm Wheat Straw Pellet Production Line

- Application: Agricultural waste recycling and biofuel pellet production

- Production Capacity: 2–2.5 tons per hour

- Finished Pellet Size: 3mm and 5mm diameter

- Raw Materials: Wheat straw, crop stalks, plant residues

- Process Flow:

- Raw material → Grinding → Drying → Pelletizing → Cooling → Screening → Packing

- ※ Process layout refers to the attached engineering drawing.

Main Equipment Configuration:

- Straw shredder

- Hammer mill (132KW)

- Rotary dryer (φ1.8×14m)

- Straw pellet machine (2×90KW)

- Counterflow cooler

- Packing machine

- Centralized control system

Installation & Operation Detail

- Project Start Time: May 8th, 2021

- Installation Period: Customer self-installed

- RICHI Support Engineers: Provide remote technical guidance

- Total Power Consumption: 50.73 KW

- Labor Requirement: 3–5 persons

- Warranty & After-sales:

- 12 months warranty excluding wear parts, with free lifetime technical support

Tailored Solution by RICHI

This client needed to process dry wheat straw into durable 3mm and 5mm fuel pellets. The main challenges included low bulk density, fiber stiffness, and uneven moisture content.

RICHI adopted a combination of heavy-duty shredding, fine grinding, and a rotary drying system to prepare the raw material.

For pelletizing, a dual-machine configuration ensures continuous output while preventing mold clogging caused by fiber buildup.

The automated control system enables real-time moisture monitoring and stable pellet shaping, making the line suitable for bio-fuel producers and agricultural recycling enterprises.

2 – 2.5

Production (ton/hour)

6

Pellet size (mm)

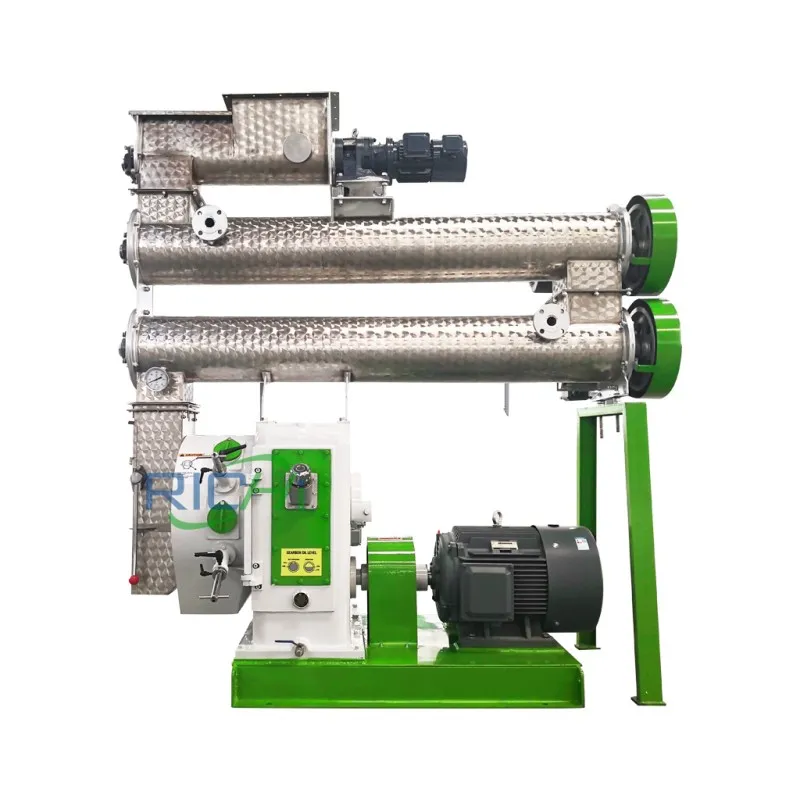

2. Wood Pellet Making Machine South Africa Project

- Project Location: South Africa

- Project Name: 2–2.5T/H Wood Pellet Production Line

- Application: Wood waste recycling and fuel pellet production

- Production Capacity: 2–2.5 tons per hour

- Finished Pellet Size: 6mm diameter

- Raw Materials: Sawdust, wood chips, shavings

- Process Flow:

- Raw material → Crushing → Drying → Pelleting → Cooling → Screening → Packing

- ※ Process layout refers to the attached engineering drawing.

Main Equipment Configuration:

- Wood chipper

- Hammer mill (132KW)

- Rotary dryer (φ1.8×14m)

- Wood pellet press machine (2×90KW)

- Counterflow cooler

- Automatic bagging machine

- Intelligent control system

Installation & Operation Detail

- Project Start Time: October 20th, 2022

- Installation Period: 10 days

- RICHI On-Site Engineers: 2 mechanical engineers + 1 electrical engineer

- Factory Layout: Rectangular plant layout, single-line operation

- Occupied Space by RICHI Equipment: 600 m²

- Total Power Consumption: 480 KW

- Labor Requirement: 5–6 workers per shift

Tailored Solution by RICHI

The key challenges were high raw material moisture and mixed wood hardness. To solve this, we integrated a rotary drum dryer for uniform moisture reduction, and a two-pellet-mill configuration to ensure stable output.

The system allows full automation with centralized control, low manpower requirements, and consistent pellet quality, suitable for both domestic supply and export readiness.

10 – 12

Production (ton/hour)

3 – 8

Pellet size (mm)

3. Forage Grass Pellet Making Machine South Africa Project

- Project Location: South Africa

- Project Name: 10T/H Forage Grass Pellet Production Line

- Application: Cattle feed (powder and pellets for cattle farm use)

- Production Capacity: 10-12 tons per hour

- Finished Pellet Size: 3mm, 5mm, 8mm pellets and powder

- Raw Materials: Corn, soybean meal, other grains, and 50% forage grass

- Process Flow:

- Raw material receiving → Grinding → Batching & Mixing → Pelletizing → Cooling → Crumbling → Screening → Packing → Finished product storage

Main Equipment Configuration:

- Feed hammer mill (110KW)

- Feed mixer (1000kg/batch)

- Batching scale (1000kg/batch)

- Feed pellet machine (110KW)

- Cooling machine (Model: SKLH20*20)

- Crumbler machine (Model: SSLG15*150)

- Automatic packing machine

- Full automatic control system

Installation & Operation Detail

- Project Start Time: March 17th, 2017

- Installation Period: 60 Days

- RICHI On-Site Engineers: 3 engineers for on-site supervision and training

- Factory Layout: Integrated layout customized for cattle farm efficiency

- Occupied Space by RICHI Equipment: Approximately 1,200 square meters

- Total Power Consumption: 350KW

- Labor Requirement: 6-7 workers

Tailored Solution by RICHI

The most distinctive feature of this project is the customer’s requirement to mix grains with 50% forage grass as raw materials. In addition, the production line must produce pellets in three different diameters: 3mm, 5mm, and 8mm.

Based on the characteristics of fibrous forage grass, RICHI adopted a precise batching system. After pelleting, the system allows for dual-mode output of both powder and pellets.

The entire production line is equipped with a fully automatic control module and requires only 6–7 workers for efficient operation. These customized configurations ensure stable performance on the cattle farm and offer excellent flexibility for future feed formula adjustments.

1 – 2

Production (ton/hour)

2 – 4

Pellet size (mm)

4. Chicken Feed Pellet Making Machine South Africa Project

- Project Location: South Africa

- Project Name: 1–2T/H Chicken Feed Pellet Production Line

- Application: Animal feed pellet production, mainly for chicken feed

- Production Capacity: 1–2 tons per hour

- Finished Pellet Size: 2mm and 4mm

- Raw Materials: Corn (maize), soybean meal

- Process Flow:

- Raw material → Crushing → Mixing → Pelleting → Cooling → Packing

- ※ Process layout refers to the attached engineering drawing.

Main Equipment Configuration:

- Hammer mill (11KW)

- Poultry feed mixer machine (3KW)

- Animal feed pellet press (22KW)

- Cooling machine (0.93KW)

- Boiler: No boiler

Installation & Operation Detail

- Project Start Time: May 8th, 2021

- Installation Period: Customer self-installed

- RICHI Support Engineers: Provide remote technical guidance

- Total Power Consumption: 50.73 KW

- Labor Requirement: 3–5 persons

- Warranty & After-sales:

- 12 months warranty excluding wear parts, with free lifetime technical support

Tailored Solution by RICHI

During the chicken feed pellet making machine South Africa project installation process, RICHI team provided efficient remote technical guidance through a WeChat after-sales service group. We promptly answered client queries and offered specific operational suggestions.

Regarding motor wiring, the technical staff gave detailed instructions on correct circuit connections. For equipment positioning and orientation, we provided precise location and adjustment plans. In terms of steel structure welding, we offered step-by-step welding procedures and important precautions to ensure structural stability and safety, thereby preventing operational failures caused by installation errors.

Meanwhile, some complex issues were discussed internally by the technical team before providing feedback to the client, ensuring that the proposed solutions were both scientific and practical.

Thanks to this series of precise and patient remote support efforts, the client successfully completed the equipment installation and commissioning. The animal feed processing plant project was ultimately put into production smoothly and received positive feedback from the client. You can also find more cases on our youtube channel.

Pellet Machine Market Outlook in South Africa

1. Abundant Raw Material Resources

South Africa has a wealth of agricultural residues and wood processing by-products, including corn stalks, bagasse, and sawdust. These raw materials are widely available and concentrated in areas with well-developed infrastructure, ensuring a stable and cost-effective supply chain for pellet production.

This natural advantage creates an ideal environment for the use of pellet making machine South Africa solutions in both the feed and biomass fuel sectors.

2. Well-Developed Infrastructure Advantages

The country boasts developed farming regions, extensive road networks, reliable electricity, and a skilled labor force. These factors provide a robust foundation for establishing and operating biomass pellet plants.

With strong infrastructure in place, manufacturers and investors can confidently deploy pellet making machine South Africa systems for large-scale production, reducing operational costs and boosting productivity.

3. Policy-Driven Green Energy Transition

The South African government actively supports the development of biomass fuel and wood pellet energy through initiatives like the Climate Change Act and the Integrated Resource Plan.

A notable project currently under construction is a 25MW biomass power plant that will utilize local wood pellets for power generation.

4. Growing Diversified Market Demand

There is a strong demand for high-quality feed pellets in the livestock industry, particularly for cattle, poultry, and sheep.

Concurrently, the renewable energy sector is increasingly replacing coal with wood pellets. The biomass boiler market is projected to grow at a compound annual growth rate of 7.1% over the next six years.

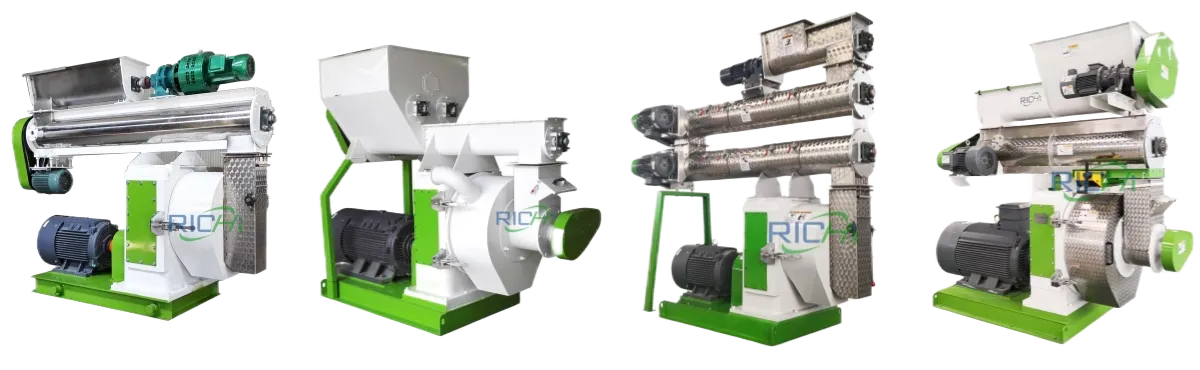

Types of Pellet Mills We Offer in South Africa

If you’re looking for a reliable pellet making machine for sale in South Africa, RICHI offers a full range of solutions.

Our pellet mill for sale South Africa lineup covers various models to meet the needs of feed and biomass pellet production across different scales and industries.

1. Animal Pellet Making Machine South Africa: Types of Pellet Mills for Animal Feed

RICHI MACHINERY

Generally used to make animal feed pellets and cat litter pellets. We also support customized pellet making machine.

SZLH250 Feed Pellet Mill

- Capacity: 1.0-1.5 tons/hour

- Main Power: 15–22 kW

- Application: Poultry (chicken, layer, broiler), rabbit, goat

- Finished Pellet Size: 2-12mm

SZLH320 Feed Pellet Mill

- Capacity: 3-4 tons/hour

- Main Power: 22–37 kW

- Application: Poultry, pigs, rabbits, goats

- Finished Pellet Size: 2-12mm

SZLH420 Feed Pellet Mill

- Capacity: 10-12 tons/hour

- Main Power: 55-110 kW

- Application: Cattle, pigs, poultry, livestock

- Finished Pellet Size: 2-12mm

SZLH508 Feed Pellet Mill

- Capacity: 15-16 tons/hour

- Main Power: 110-160 kW

- Application: Poultry, cattle, pigs, large livestock farms

- Finished Pellet Size: 2-12mm

SZLH678 Feed Pellet Mill

- Capacity: 30–33 tons/hour

- Main Power: 250 kW

- Application: Poultry, cattle, pigs, large livestock farms

- Finished Pellet Size: 2–12 mm

MZLH320 Biomass Pellet Mill

- Capacity: 0.2-0.3 tons/hour

- Main Power: 15–22 kW

- Application: Straw, grass, alfalfa, cat litter

- Pellet Size: 4-12 mm.

MZLH350 Biomass Pellet Mill

- Capacity: 0.3-0.5 tons/hour

- Main Power: 22–37 kW

- Application: Straw, grass, alfalfa, cat litter

- Pellet Size: 4-12 mm

2. Wood Pellet Making Machine South Africa: Types of Pellet Mills for Wood Pellets

RICHI MACHINERY

Function is used to produce biomass combustion pellets. RICHI support customized pellet mill equipment. Tell us your output and needs to get the most suitable equipment for you.

MZLH420 Biomass Pellet Mill

- Capacity: 1-1.2 tons/hour

- Main Power: 37–90 kW

- Application: Straw, wood sawdust, alfalfa

- Pellet Size: 4-12 mm

MZLH520 Biomass Pellet Mill

- Capacity: 1.5-2 tons/hour

- Main Power: 90-132 kW

- Application: Wood chips, straw, cat litter

- Pellet Size: 4-12 mm

MZLH678 Biomass Pellet Mill

- Capacity: 2.5–3 tons/hour

- Main Power: 132-185 kW

- Application: Wood chips, straw, cat litter

- Pellet Size: 4–12 mm

3. Straw & Pasture Pellet Making Machine South Africa: Types of Pellet Mills for straw and Pasture

RICHI MACHINERY

The CZLH series straw and forage pellet machines are designed for efficiently compressing agricultural residues like straw, grass, and alfalfa into high-density pellets.

With models ranging from 0.5 to 8 tons per hour, they meet the needs of small farms to large-scale industrial production.

CZLH320 Straw Pellet Mill

- Capacity: 0.5–0.6 tons/hour

- Main Power: 22 kW

- Force Feeder Power: 0.75 kW

- Pellet Size: 4–12 mm

- Application: Suitable for processing straw, pasture, rice husks, and alfalfa into pellets for small-scale production or farm use.

CZLH350 Straw Pellet Mill

- Model: CZLH350 Straw & Forage Pellet Machine

- Capacity: 1.0–1.2 tons/hour

- Main Power: 37 kW

- Force Feeder Power: 0.75 kW

- Pellet Size: 4–12 mm

- Application: Ideal for small to medium-sized forage pellet producers using materials like corn stalks, alfalfa, rice husks, and other agricultural residues.

CZLH420 Straw Pellet Mill

- Capacity: 1.8–2.0 tons/hour

- Main Power: 90 kW

- Force Feeder Power: 1.5 kW

- Pellet Size: 4–12 mm

- Application: Designed for professional forage processing plants producing large volumes of pellets from straw, grass, and alfalfa.

CZLH520 Straw Pellet Mill

- Capacity: 2.8–3.0 tons/hour

- Main Power: 132 kW

- Force Feeder Power: 1.5 kW

- Pellet Size: 4–12 mm

- Application: Suitable for commercial-scale production of straw, pasture, or alfalfa pellets in feed or biomass energy applications.

CZLH678 Straw Pellet Mill

- Capacity: 4.0–5.0 tons/hour

- Main Power: 185 kW

- Force Feeder Power: 1.5 kW

- Pellet Size: 4–12 mm

- Application: Ideal for industrial-scale agricultural waste pellet production using materials such as corn stalks, grasses, and crop residues.