100-150 KG/H floating fish feed production line in Ukraine

The 100-150 KG/H floating fish feed production line in Ukraine processes grain into high protein nutrition.

Project Overview

RICHI Manufacture has started to build a prospect of floating fish feed production line in Ukraine in January, 2024.

100 – 150

Production (kilograms/hour)

2 – 5

Pellet size (mm)

- Project Country: Ukraine

- Project Name: floating fish feed production line

- Project Output: 100-150 KG/H

- Customer Raw Material: Soybean meal, wheat, fish meal, black meal, maize

- Finished product & size: 2 mm, 3 mm, 5 mm.

- Main equipment of the project: hammer mill, mixer, extruder, dryer, spraying machine

- Project start time: 2024.01.04

- Project installation period: 10 days

- Engineers On-site: 2 engineers

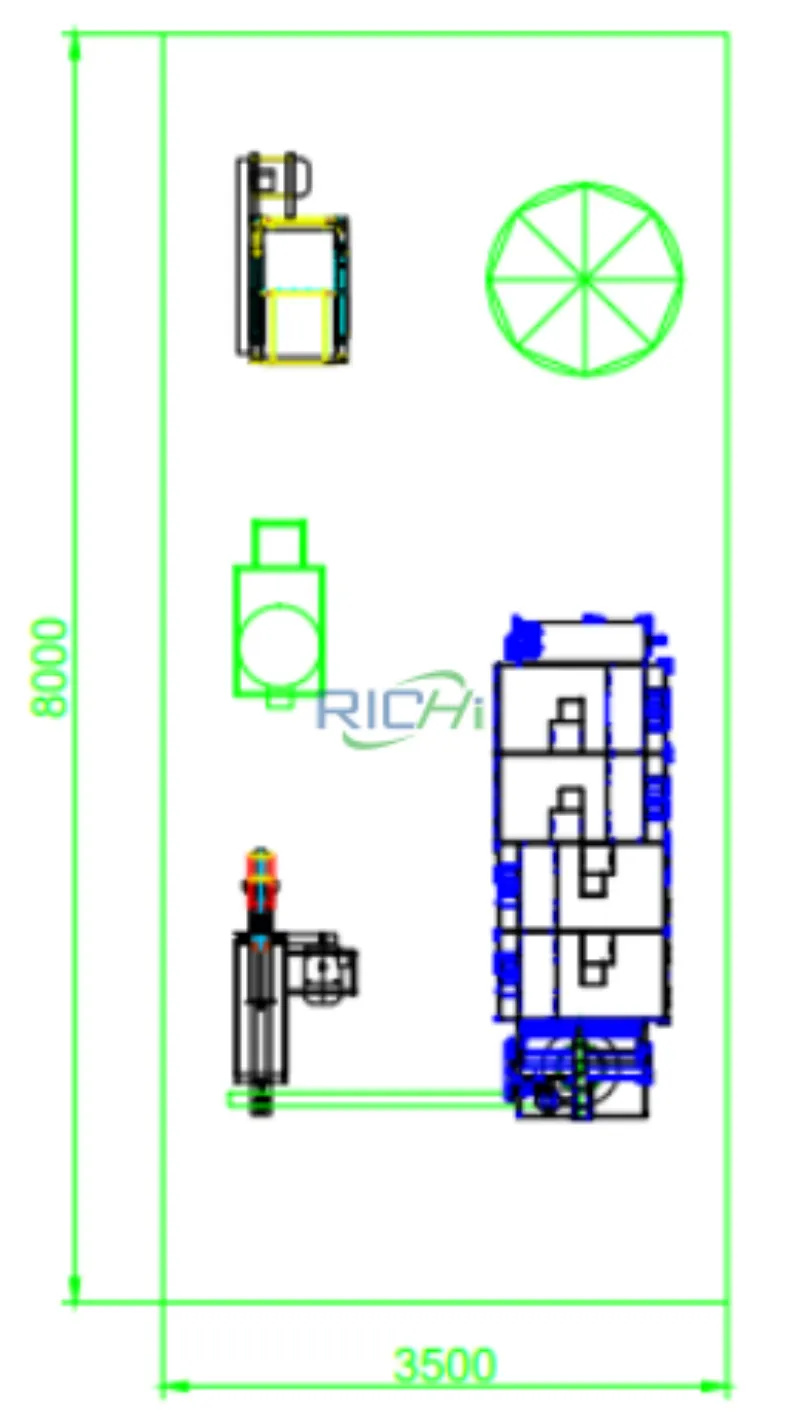

- Our project area: 8 m X 3.5 m X 4 m

- Power Consumption: 50.74 kW/hour

- Labor Requirement: 3 workers

- Warranty period: In addition to wearing parts, 12 months after the completion of installation, permanent free technical support.

Client Background & Challenges of building 100-150 KG/H floating fish Feed Production Line in Ukraine

The client operates a local aquaculture cooperative located in Ukraine. Due to the long-term high demand for commercial feed, the previous feed procurement model would have cost too much. Therefore they decided to build a small-scale floating fish feed production line.

In this way, not only can the significantly reduce their farming costs, but also provide a more reliable and economical feed supply for their own fish farm and nearby partners.

However, there were three challenges at the start of the project. Firstly, the budget was limited. The client urgently needed a cost-saving solution without compromising the quality of the output. Secondly, the client’s available workshop space is very tight. It can’t match the traditional large scale equipment.

Lastly, the customer had very high demands on the floatability of the feed. As the feed will be mainly used for pond farming, the feed pellets must have good and stable floatability to ensures the fish can feed properly and reduces feed waste.

Project Video Showcase

Before diving into the customized solution we provided for our Ukrainian client, take a moment to watch these two videos for a real-world look at the project site and machine performance. You can check more cases on our youtube channel.

Video 1: Project Overview

This video captures the full process from equipment delivery and installation to successful commissioning. It highlights the compact layout, efficient design, and real operation of RICHI’s 100-150 KG/H floating fish feed production line.

Video 2: Extruder Machine Test Run

In this test run video, you’ll see the small fish feed extruder in action—feeding, extrusion, shaping, and output. The floating fish feed produced shows excellent expansion and buoyancy, meeting the high standards of our Ukrainian customer.

Tailored Solution & Equipment Layout

To meet the client’s unique requirement, RICHI customized a 100-150 KG/H floating fish feed production line in Ukraine. Consider of the tight space of the workshop, the engineering team adapt a U-shaped layout (As shown in the figure on the right).

The engineering design maximizes the use of the space while ensuring a smooth production process. All equipment was prioritized to suit small sites, low energy consumption and ease of operation in order to fit the customer’s budget and operating conditions.

Main equipment of the whole production line include:

- high-efficiency crusher: used for crushing soybean meal, wheat, fish meal, and other ingredients.

- horizontal ribbon animal feed mixer: used for uniform blending.

- screw conveyor: used for transfer the well-mixed material to the extruder.

- floating fish feed extruder machine: used for cook, shape and expand the material into floating fish feed pellets through high temperature and pressure.

- mesh type drying machine: provides more uniform and gentle drying through multi-layer belt transmission.

- spraying machine: coat the dried feed pellets with oil, vitamins or attractants.

The equipment is designed to support flexible switching of 3-10 mm particles and has precise control over key parameters such as temperature and humidity to ensure the stable flotation performance.

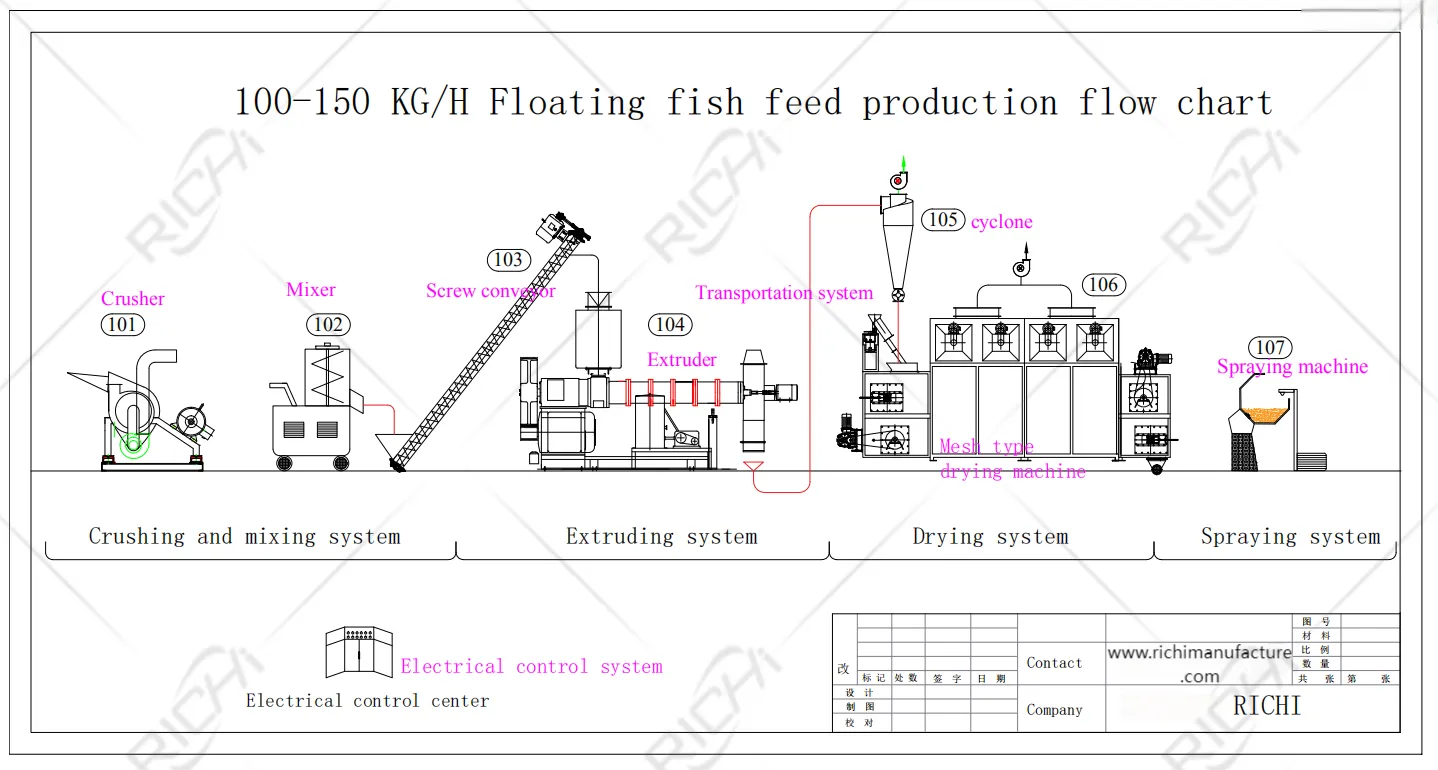

Process Design for the floating fish feed production line in Ukraine

The feed production line adopts four stage process: crushing and mixing(crusher and mixer), extruding(extruder), drying(mesh type drying machine), spraying(spraying machine). The whole process of the fish feed mill plant helps to optimize the material flow and ensures the floatability of the pellet. The process design for floating fish feed production line in Ukraine is suitable for all small and medium scale farming production.

Installation & Problem Solving

The entire installing process of the 100-150 KG/H floating fish feed production line in Ukraine only last 10 days. RICHI sent two engineers to the construction site for technical guidance.

With the prefabricated layout and modularized equipment, the installation process was efficient and smooth. During the commissioning stage, the customer found that the pellets were not floating.

RICHI’s engineers, after checking the machinery and parameters one by one, determined that the root cause of the problem was a mismatch in the customer’s formulation.

After suggesting, they increased the proportion of corn starch, thus the floating problem was solved successfully. The customer was very satisfied.

Cost & Value

The whole 100-150 KG/H floating fish feed production line in Ukraine of investment is quoted at around $15,000 -$30,000.

Investment Cost Quotation

| Project | Project Content | Estimated Amount(USD) |

| Core Equipment | crusher, mixer, extruder, fryer, sprayer | $12,000 – $20,000 |

| Electronic Control System | Distribution cabinet, electrical control unit, etc. | $1,500 – $2,500 |

| Installation & Commission | site support by engineers | $1,000 – $2,000 |

| Transportation & taxes | Delivery to Ukrainian port | $500 – $1,500 |

| Others | Factory Utilities, Cables, Civil work | Covered by customer |

| Total | Overall Project Investment | $15,000 – $30,000 |

This is extremely cost-effective for small cooperatives. The client has significantly reduced feed costs within the fist year of operation.

The client has the flexibility to adjust the nutritional structure and floating effect by producing their own formulated pellets. This improves aquaculture efficiency and realizes sustainable returns in the long term.

Client Feedback & Future Plan

After the project was successfully put into operation, the customer highly recognized the operation effect of the whole floating fish feed production line in Ukraine.

Before launching the project, the client purchased floating fish feed from local suppliers at about $480 per ton. After adopting the RICHI production line and merely using the locally sourced raw material(such as corn, soybean and fish meal) plus the electricity and labor cost. The total cost dropped to around $290 per ton. With a daily output of 1 ton, the client now saves about $130 per day(about $3,000-4,000 per month). The client claims that the full equipment investment is expected be recover with 8 months.

The client wrote in a customer return survey three months after commissioning:

“We used to reply on buying commercial feed, prices were high and quality was all over the place. Honestly, it made us nervous. Now we can produce it ourselves. The pellets float well and we can tweak the formula when needed. Most importantly, the cost has gone down. Your engineers were super professional and quick to help when any issue came up. This whole experience really gave us confidence to grow our farm further.”

Start Your fish Feed Production Journey

The success of this 100-150 KG/H floating fish feed production line in Ukraine not only helps the Ukrainian client to realize cost reduction and efficiency, but also allows them to see greater possibilities in terms of farming scale and market expansion.

If you are also looking for a cost-effective, easy-to-operate, stable and efficient fish feed production line, RICHI can provide you with professional support and customized solutions, no matter what country you are in or what stage you are at.

Want to know more about real cases or get a customized solution? Feel free to contact RICHI and we will be happy to help you.