5-6 T/H Floating Fish Feed Plant in Russia

Discover how RICHI built a 5-6 T/H floating fish feed plant in Russia with a customized design, advanced extruder line and efficient production solution.

Project Overview

RICHI Manufacture has started to build a prospect of Floating Fish Feed Plant in Russia in August, 20201. The customer is very satisfied with the complete fish feed plant and has made a profit.

5 – 6

Production (ton/hour)

1.5 – 6

Pellet size (mm)

- Country: Russia

- Project Name: Floating Fish Feed Plant

- Raw Material: fish meal, soybean meal, corn, and wheat bran, supplemented with oils and vitamin premixes

- Finished Product Size: 1.5 mm-6 mm fish feed pellets

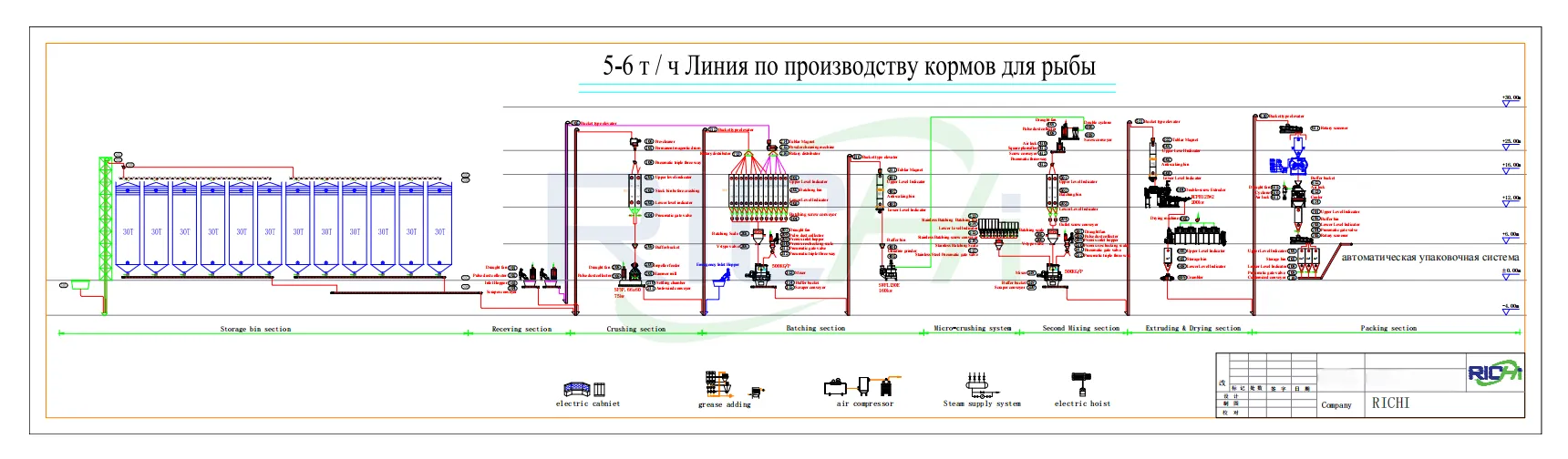

- Main Equipment: 2×30 T silo storage system/Raw material handling system/Primary crushing & first batching system

Fine-grinding & Second Batching System/Fish feed extruder/Dryer/Screening & vacuum spraying system/Screening & packaging system - Installation Time: 90 days

- Project Start Date: August 17, 2021

- Engineers On-site: 5 engineers

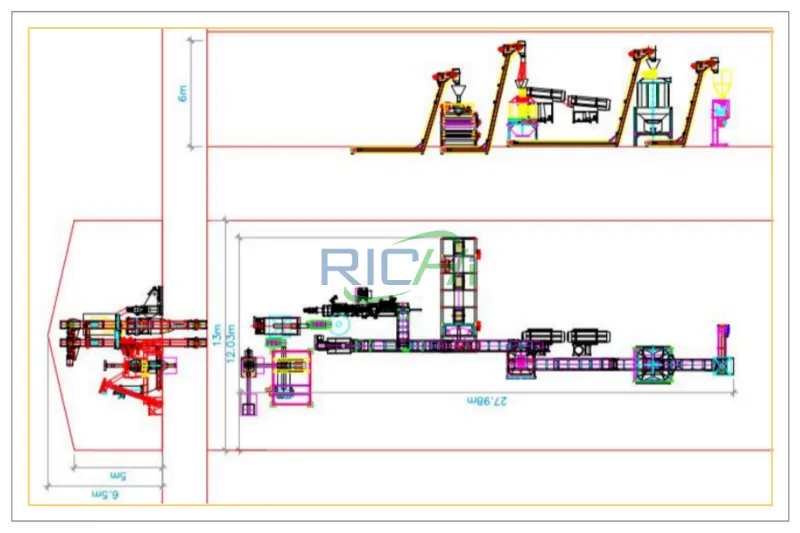

- Working Area Required: 3700 square meters

- Power Consumption: 550 KW

- Labor Requirement: 7 workers per shift

- Warranty: 12 months for main equipment, lifetime free technical support

Client Background & Challenges of building Floating Fish Feed Plant in Russia

The client is a Russian company specializing in the production of high-quality floating fish feed, with particle diameters ranging from 1.5mm to 6mm. As the aquaculture industry continues to grow, the company identified the need to upgrade its manufacturing capabilities in order to enhance production efficiency and stay competitive in the market.

By focusing on consistent quality and reliable output, the client primarily supplies its fish feed products to local and neighboring markets. This regional distribution strategy helps the company meet increasing client demand while strengthening its presence in the surrounding areas.

However, the client also encountered a number of challenges during the project planning process:

First, the existing plant space was too limit to accommodate a full-scale fish feed production line. This space limitation posed serious obstacles to the layout and future operation of the manufacturing process.

Secondly, the customer has very high requirements for the quality and the equipment performance. They conducted a comprehensive comparison of several suppliers from Europe and China. They focused on equipment durability, productivity, energy consumption levels and after-sales service. It was a big challenge for us.

Tailored Solution & Equipment Layout for 5-6 T/H Floating Fish Feed Plant in Russia

After fully understanding the client’s needs, RICHI developed a customized solution that comprehensively addressed all the challenges faced by the client.

Firstly, to address the lack of space in the existing plant, we suggested converting the existing plant into a raw material and finished product warehouse. At the same time, a new 5-6 T/H fully automated fish feed production line was built on the nearby area in order to ensure the smooth running of the subsequent production.

Secondly, in terms of equipment selection, RICHI provided a complete set of solutions that met European quality standards and stayed within the client’s budget.

The entire line is fully automated. It covers the complete production process of raw material reception, primary and ultra-micro crushing, primary and secondary mixing, bulking, drying, granulation, vacuum spraying, cooling and packaging.

Process Design for the 5-6 T/H Floating Fish Feed Plant in Russia

The concrete 5-6 T/H floating fish feed plant in Russia process are as follow:

1. raw material handling system:

Whether the material is bulked or bagged, first they all enter the storage room together. Then, A primary sieve and a magnet separator can remove the impurities such as stones and metals. After that, the granular material is fed into the crushing area. Whereas the powder material goes directly into the batching warehouse.

2. Primary crushing & first batching system:

The primary pulverizing system is using to pulverize the raw material. Then, the crushed material is accurately distributed to the batching bins based on a predefined feed formula.

3. Fine-grinding & Second Batching System:

In response to the need for finer particles in some formulations, the production process includes a special step of fine grinding stage. Subsequently, a high-precision screening system is using to screen the material.

Following this, the second formulation system is under computer control. At there, the fine powders are accurately proportioned with micro-ingredients, fats and oils, and other additives in order to produce the ideal feed formulation.

4. Extrusion, Drying, Crushing & Spraying:

First, the material enters the fully automatic extruding system mainly using the floating fish feed extruder machine to enhance expansion under saturated steam tempering conditions. Then, expanded feed enters the circulating belt dryer to reduce the feed moisture to less than 10%.

After drying, the feed passes through a vacuum spraying system, where oil and attractants are evenly applied in order to enhance palatability and nutritional value.

5. Cooling, Screening & Packing:

Once after spraying, the hot pellets are cooled down to room temperature to prevent moisture condensation during storage. Then, they are screened to remove fines and broken particles. Thus to ensure the uniform product quality. Finally, the finished pellets are automatically weighed, bagged, and sealed by the packaging system.

Installation & Problem Solving of 5-6 T/H Floating Fish Feed Plant in Russia

The equipment of this fish feed mill plant was shipped by rail, using 21 40-foot containers, with an overall shipping cycle of about 40 days. After the goods arrived in Russia, the project team started the installation work according to the plan in an orderly manner. The whole installation period was about 90 days, covering steel rigidity and steel structure.

Challenges during installation and effective solutions:

| Challenges During Installation | Effective Solutions | |

| 1. Limited on-site space | The narrow site space has fine scheduling requirements for lifting operations, steel structure assembly and material stacking. So a reasonable design and installation program is needed to prevent site congestion. | RICHI made a dynamic construction plan was drawn up according to the actual daily progress, with flexible adjustments to the crane operating window and construction staffing. |

| 2. Cold weather conditions | During the construction period, the temperature is low. Thus, special attention should be paid to the quality of welding and protective measures for equipment and materials. | In response to the effects of low temperatures, RICHI adopt the weld preheating technology and add the temporary insulation protection to some equipment. |

Customer Feedback & Future Plan of Floating Fish Feed Plant in Russia

After the successful commissioning of the line, the client highly appreciated the performance of the 5-6 T/H floating fish feed plant in Russia.

In the feedback, the client says:

“Choosing RICHI was the right decision, your expertise and technical support exceeded our expectations.”

After the successful completion of the project, the client placed two additional orders for subsequent installations. RICHI is looking forward to working with this client again as they plan to expand their production capacity in the near future to further strengthen their market position. You can also check more information on our youtube channel.

Start Your Fish Feed Production Journey

If you’re encountering challenges similar to those of our floating fish feed plant in Russia (such as limited plant space, tight budgets, and the pursuit of high-quality fish feed production) RICHI is ready to support you. Whether you’re aiming for flexible pellet sizes or striving to meet high production standards, we deliver tailored solutions that align with your goals.

By combining deep industry knowledge with practical experience, RICHI continues to serve a growing number of clients who value efficiency, innovation, and long-term reliability. As more businesses choose RICHI each year, we remain committed to delivering results that exceed expectations.

So instead of compromising on quality or productivity, let RICHI help you build a smart, sustainable, and high-performance floating fish feed production line. Reach out to us today and take the first step toward transforming your aquafeed business.