Fish Feed Pellet Machine Price

Fish feed pellet machine price varies according to brand, type, model, capacity and configuration. For example, RICHI SZLH series fish feed pellet machine prices range from $7,500 to $85,000, RICHI fish feed pellet extruder prices range from $3,000 to $200,000. RICHI fish feed pellet machine can produce sinking fish, floating fish, shrimp, crabs and other aquatic feed and pet feed. If you want to buy a machine for producing fish feed or pet food, you can contact us.

What Is The Fish Feed Pellet Machine?

A fish feed pellet machine is specialized equipment used for producing floating, sinking, and slow-sinking pellets for a wide range of aquatic species such as tilapia, catfish, carp, trout, and shrimp. Raw materials including corn, soybean meal, fish meal, wheat bran, rice bran, vitamins, and minerals are processed into uniform, nutritionally balanced pellets that improve feed utilization and support efficient aquaculture production. With advanced control over pellet size, density, and cooking degree, fish feed pellet machines are widely used in medium and large farms as well as commercial feed mills of all scales.

To meet different process requirements and production goals, we offer three major types of equipment:

- Single-Screw Extruder – This equipment offers stable performance and low energy consumption, making it an ideal choice for producing both floating and sinking feed, and is primarily used in small and medium-sized production lines.

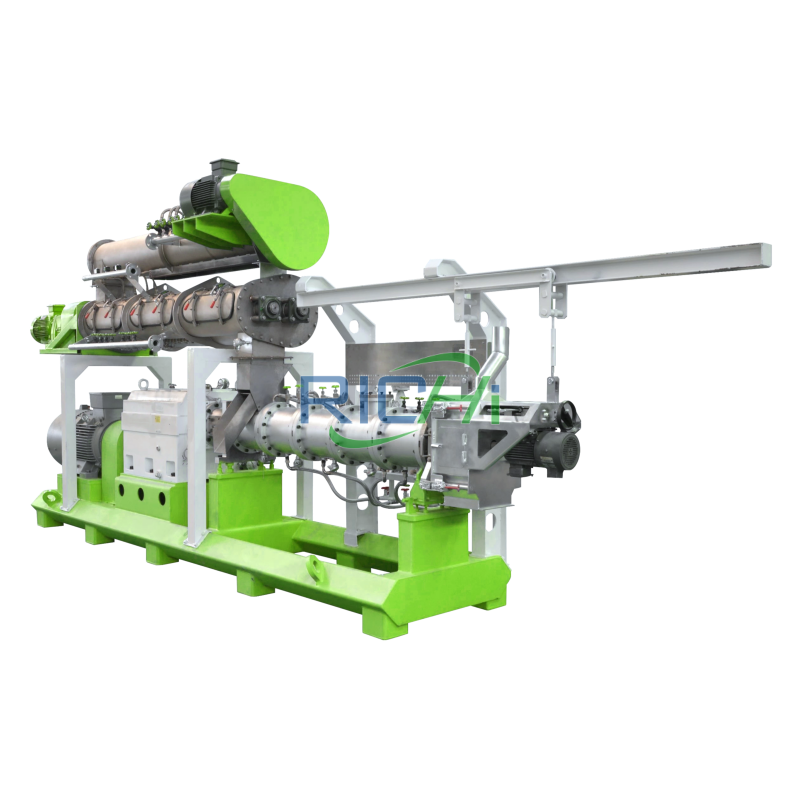

- Twin-Screw Extruder – Designed for high-value and precision feed production, featuring higher expansion rate, stronger shear force, and superior cooking uniformity. It is ideal for premium aquafeed, shrimp feed, pet food, and specialty formulations.

- Ring Die Pellet Machine – It is mainly used for producing sinking feed, shrimp feed, or other animal feeds. This equipment is highly efficient, produces pellets with high strength, and has low operating costs, making it suitable for large-scale continuous production.

For the investment range, the fish feed pellet machine price typically falls between USD 3,000 and USD 200,000. Entry-level models are suitable for medium and large farms that need stable and efficient feed production, while high-capacity and fully automated industrial models occupy the upper end of the range and are widely used in commercial feed mills of all scales. We also offer customized configurations to meet different process standards, production targets, and budget levels.

Different Types With Different Fish Feed Pellet Machine Prices

The fish feed pellet machine price varies significantly depending on the type of equipment and the production performance you expect. Our product range covers both ring die pellet machines for sinking aquatic feed and screw extruders for floating, slow-sinking, and specialty feeds. Each type operates under a different working principle, offers different degrees of starch gelatinization, pellet shape, density control, and capacity range. Because of these technical differences, the price for each category naturally falls into a different level. Understanding these distinctions helps you choose the most suitable machine according to your farm size, processing needs, and investment budget.

Working Principle Of Fish Feed Pellet Machine

Understanding the working principles of different fish feed pellet machines helps in judging equipment performance, pellet quality, and the rationality of pricing. Currently, fish feed processing mainly uses two forming methods: mechanical pressing pelleting and extrusion pelleting.

Fish feed pellet mills rely on steam conditioning and high-pressure mechanical pressing to complete pelleting. The material is heated and softened, partially gelatinized, in the conditioner before entering the pelleting chamber. Pressure rollers continuously compress the material against the inner wall of the ring die, forcing it into the die holes under high pressure and then cutting it into shape by a cutter. The compression ratio of the ring die, the hardness of the wear-resistant parts, and the structure of the pressure rollers directly affect the water resistance and forming quality of the pellets. This equipment is mainly used for producing sinking fish feed, commonly used in the processing of catfish, benthic fish, and shrimp feed.

In contrast, fish feed extruders rely on high temperature, high pressure, and high shear to achieve deep maturation and expansion of the material. After the material enters the extrusion chamber, the screw continuously propels, mixes, compresses, and shears the material, causing the temperature and pressure to rise rapidly. The raw starch is fully gelatinized and undergoes an expansion reaction. When material is ejected from the die orifice, the instantaneous pressure drop causes immediate expansion, resulting in floating or slow-sinking pellets. Twin-screw extruders excel in stability, curing degree, and control precision, thus their manufacturing cost is higher, leading to a higher overall fish feed pellet machine price. They are widely used in the production of floating fish feed, slow-sinking feed, high-end formulated feed, and pet food, making them the preferred choice for farms and feed mills seeking high-value-added products.

Whether choosing a ring die extruder for producing sinking pellets or an extruder for producing floating and high-end feeds, users should make a comprehensive judgment based on pellet type, raw material characteristics, and product positioning to find the most cost-effective solution.

Different Fish Feed Pellet Machine Price With Different Parameter

— RICHI Machinery —

The fish feed pellet machine price varies not only because of different technical parameters but also because different machine types—such as ring die pellet mills, single-screw extruders, and twin-screw extruders—are designed for different processing principles and application scenarios. Each type naturally falls into a different price range.

| Model | SZLH250 | SZLH320 | SZLH350 | SZLH420 | SZLH508 | SZLH558 | SZLH678 | SZLH768 |

| Main Motor Power | 22KW | 37KW | 55KW | 110KW | 160KW | 185KW | 250KW | 315KW |

| Feeder Power | 0.75KW | 0.75KW | 0.75KW | 1.5KW | 1.5KW | 1.5KW | 1.5KW | 1.5KW |

| Capacity | 1-2T/H | 3-4T/H | 5-6T/H | 10T/H | 15T/H | 20T/H | 30T/H | 40T/H |

| Model | SPHS75x2 | SPHS120*2 | SPHS150*2 | SPHS185*2 | |

| Main Motor Power | 55KW | 90KW | 110KW | 200KW | 355KW |

| Feeder Power | 1.5KW | 1.5KW | 1.5KW | 1.5KW | 2.2KW |

| Output | 0.5-1.0T/H | 1.5-2.0T/H | 3.0-4.0T/H | 5.0-6.0T/H | 8-10T/H |

| Model | DGP-90B | DGP-120B | DGP-160B | DSP-90B | DSP-135B |

| Main Motor Power | 37 | 55 | 90 | 37 | 75 |

| Feeder Power | 0.75 | 202 | 3 | 7.5 | 7.5 |

| Output | 0.2-0.4T/H | 0.5-0.6T/H | 0.8-1.0T/H | 0.5-0.6T/H | 0.8-1.0T/H |

| Tempering Power | / | / | / | 1.1 | 2.2 |

RICHI MACHINERY

Different Fish Feed Pelletizer Price In Global Project Cases

RICHI Machinery has completed a lot of sales of fish feed pellet making machines at home and abroad, and helped customers build fish feed plants. Our projects have covered 140+ countries and regions. Fish feed pellet machine price varies significantly across global project cases due to differences in raw materials, required pellet type, automation level, and production capacity. By reviewing real installations from different countries, buyers can better understand how local farming practices, feed formulas, and market scales influence equipment selection and overall investment.

Production Line for 1.5-2T/H Extruding Fish Feed/Pet food & 5-6 T/H Animal Feed

- Country: Iran

- Guide Price: $500,000

- Customer Feedback: “Our farm needed both fish feed and livestock feed production in the same facility, so we invested in the 1.5–2T/H extruding fish feed & pet food line together with the 5–6T/H animal feed line. The biggest advantage we experienced is stability—both production lines run smoothly, with no downtime during peak seasons. The extruder produces very uniform floating pellets, and the pet food molds are easy to switch. The animal feed line also significantly improved feed consistency compared to our previous setup. RICHI’s engineering team guided us through layout planning, installation, and operator training. Their support was fast and professional. This project greatly increased our feed self-sufficiency and reduced purchasing costs. We are very satisfied with the overall performance.”

5-6 Tons Per Hour Floating Fish Feed Production Line

- Country: Russia

- Guide Price: $700,000

- Customer Feedback: “We were looking for a stable and high-capacity floating fish feed line, and the 5–6T/H system from RICHI fully met our expectations. The floating rate of the pellets is excellent, and the density can be adjusted easily depending on the fish species. Energy consumption is lower than we expected, and the PLC control system helps us manage production with only two operators per shift. What impressed us most was the commissioning service—RICHI technicians stayed on site until our team could operate the entire line independently. After several months of operation, the equipment continues to perform reliably, and our feed quality has noticeably improved.”

2T/h Shrimp Feed Making Machine In Indonesia

- Country: Indonesia

- Guide Price: $455,000

- Customer Feedback: “Our shrimp farm in Indonesia required high-density, water-stable sinking feed, and the 2T/H shrimp feed machine provided exactly what we needed. The pellets have excellent stability in water, and the size range is perfect for different shrimp growth stages. The upgraded conditioners and ring die design improved pellet hardness while keeping the protein structure intact. RICHI’s local installation team responded quickly to every request, and spare parts supply has been smooth. After using the machine for half a year, our feed conversion rate has improved significantly, and we have reduced feed waste in ponds. We highly recommend this equipment.”

- 5-6T/H fish feed mill plant in Russia

- Fish feed pellet plant price: $540,000

- 5T/H sinking fish feed pellet line in Uzbekistan

- Fish feed manufacturing plant price: $515,000

- 1.5-2T/H fish feed pellet line in Turkey

- Fish feed pellet plant price: $450,000

- Algeria 10T/H fish feed pelleting project

- Fish feed pellet machine price: $1,400,000

- 1-2T/H fish feed pelleting project in Indonesia

- fish feed pellet extruder machine price: $75,000

- 1T/H floating fish feed production line in Qatar

- Floating fish feed pellet machine price: $20,000

- Thailand 1T/H sinking fish feed pellet line

- Fish feed pellet machine price: $7,800

- Cote d ‘Ivoire 300-400KG floating fishing feed line

- Floating fish feed extruder machine price: $4,000

How Are Fish Feed Pellets Produced With Our Machine?

As the main machine of fish feed pellet production line or fish feed plant, fish feed pelletizer machine presses mixed fish feed into fish feed pellets. However, the production of fish feed pellets requires the entire production line to complete.

The main sections of the fish feed pellet production line include: raw material reception, raw material crushing, batching according to the formula, mixing of powder feed, adding of small materials, granulation or extruding, drying, cooling, screening of fish feed pellets, and finally packaging of fish feed pellets.

All processing sections provided by RICHI Machinery are modular. Customers can:

- build a full production line

- purchase individual machines

- customize capacity from 200 kg/h to 20 t/h

Why Choose RICHI Fish Feed Pellet Machine

RICHI Machinery has been operating for 30 years, is the most professional fish feed pellet machine manufacturer, supplier and exporter in China, and provides the factory price directly to customers.

Rich Strength

RICHI’s fish feed pellet machine and auxiliary equipment have passed ISO, CE and other international certifications, and also passed BV factory inspection.

Rich Experience

We have built animal feed and fish feed pellet production lines for more than 2,000 customers in more than 140 countries and regions around the world.

Cost-Effective

RICHI fish feed pellet machines are designed to provide high efficiency, low energy consumption, and long service life, offering an excellent balance between performance and investment.

4R Service

Reliability, rigorousness, responsiveness and reassurance. Our goal is that every customer is worry-free all the way. You can also choose us with confidence.

Choosing the right equipment involves more than just price considerations; it’s about long-term performance, efficiency, and reliability. Leveraging extensive experience in feed engineering and a global portfolio of installation projects, RICHI Machinery turnkey service provides clients with complete solutions, from process design and equipment manufacturing to installation, commissioning, training, and after-sales support, ensuring maximum value for our customers.

FAQ

To help you make a more informed investment decision, we’ve compiled a list of frequently asked questions from customers around the world. These answers will help you gain a more comprehensive understanding of feed granulator machine price.

What are the differences between fish feed pellet machine and fish feed extruder? Which is worth investing in?

+

Fish feed pellet machine is mainly used for the production of sinking fish feed and shrimp feed pellets. High density fish feed pellets are formed through the extrusion of ring die and press roller. Compared with the fish feed extruder, the fish feed pelletizer machine has lower price, higher output and easier return on investment.

Fish feed extruder can produce floating fish feed, sinking fish feed, slow sinking fish feed, dog food, cat food, hamster food, pet food and so on. Extruded feed pellets are extruded from die mouth by high speed rotation of screw and high temperature and high pressure environment. The higher temperature and pressure in the extruding process can improve the gelatinization of starch in feed, change the structure of protein and improve the utilization rate of feed. Floating feed on the water surface, better stability, easy to feed, reduce feed waste. In addition, the current profit of extruded feed is higher, in the long run, the investment of fish feed extruder machine project is more profitable.

How much does invest in fish feed mill plant cost?

+

Now let’s discuss what it costs for RICHI to build a fish feed mill plant project for a customer, excluding the infrastructure of the fish feed plant, the local labor and water and electricity costs.

- Fish feed pellet machine price, auxiliary equipment price.

- Cost of steel frame.

- Boiler system, oil adding system, air compressor, gas storage tank price.

- Transportation costs.

- Installation and commissioning costs.

- Others.

The above is basically the net fish feed mill plant cost, and the specific need to combine your own project size, equipment brand and so on to decide. If you want to invest in fish feed pellet machine project, contact us quickly for a detailed list and quotation.

I run a medium-sized tilapia farm with approximately 150,000 fish. How much should I budget for a floating fish feed pellet machine?

+

If you operate a medium-sized tilapia farm with approximately 150,000 fish and plan to produce floating feed, you will need about 1.5 tons of feed per day. Assuming you operate for 6 hours per day, we recommend our DGP-90B single-screw extruder. Its 200-400 kg/h capacity can efficiently meet your feed needs. The fish feed pellet machine price is between $3,000 and $40,000, an investment that allows for good consistency between production efficiency and feed quality while maintaining operational flexibility.

I’m a beginner. How can I choose the right fish feed pellet machine based on capacity and price?

+

For beginners planning to start a feed production operation, it’s important to choose a machine that fits both your production needs and budget. We offer small-capacity machines (0.2–1T/H) for pilot runs, medium-capacity machines (2–6T/H) for commercial production, and high-capacity industrial machines (10T/H or above) for fully automated large-scale operations. Selecting the right capacity helps control your fish feed pellet machine price while ensuring stable feed quality and efficient production. Suppliers can also provide customization to meet specific technical requirements and project budgets.