fish feed manufacturing plant

Customized designs to optimize feed quality, output and operational efficiency.

build your ideal fish feed manufacturing plant.

brief introduction

Looking for a way to boost your fish farming productivity within the high quality and low cost? Eager to start your own aquaculture product line but have no clues? Want to further expand your fish farming business but don’t know who to trust with and cooperate with? A professional fish feed manufacturing plant could be the game-changer for you.

Within a complete production unit, you can use various raw materials to produce high-output feed pellets. Stop hesitating and cooperate with us. We, RICHI, the leading figure of Chinese machinery and equipment manufacturing.

Our factory is equipped with advanced manufacturing equipment, a professional technical team and strict quality control system to ensure every machine meets international standards. We not only offer you the high-tech machines but also delivery the end-to-end solutions that help your business growth.

Usage: It can produce fish feed such as tilapia, trout, catfish, eel, salmon, herring, ornamental fish, etc.

materials: rice bran, soybean cake, silkworm pupa powder, bran, fish meal, barley flour, corn flour, vitamins, bone meal, etc.

0.5-20

Production (tons/hour)

0.6-4

Particle Size (mm)

RICHI MACHINERY

Smart Solutions: Key Features of RICHI fish feed manufacturing plant

Our fish feed making line solution has been set up to make sure the fish feed production be both efficient and eco-friendly.

Some key features are as follow:

Flexible feeding types

Supports floating, semi-floating and sinking fish feed. The finished product adapt various species, including catfish, shrimp, tilapia, ornamental fish and so on.

Multiple raw material handling

It can process both raw materials that provide plant protein, such as corn, wheat bran, and soybean meal, and those that provide animal protein, including fish meal, shrimp meal, and crab meal.

Fully automated process

The entire line is controlled via an intelligent PLC system. From raw material grinding to final cooling and packaging, the production line not only reduces labor requirements but also increases production precision.

Durable construction

All machines are built with wear-resistant materials and food-grade stainless steel. As a result, the robust construction can ensuring long-term durability.

Also, the equipment all come with temperature control system to reduce the machine depletion for a long mechanical life.

High quality & efficiency

High-speed grinding and mixing equipment of the fish feed manufacturing plant ensure the appropriate nutritional content, while built-in cooling and drying equipment enhance storage life.

Moreover, the advanced energy-saving technology and optimized process layout help lower production costs without compromising output.

Customizable solutions

According to your specific feed formula, factory layout and regional feed, all the machine parameters and line configurations could be customized.

Explore Our fish feed manufacturing plant Options: Real Cases & Technical Specs

We offer complete and scalable fish feed production solutions to different customer need. Here are one typical case and kinds of technical specs:

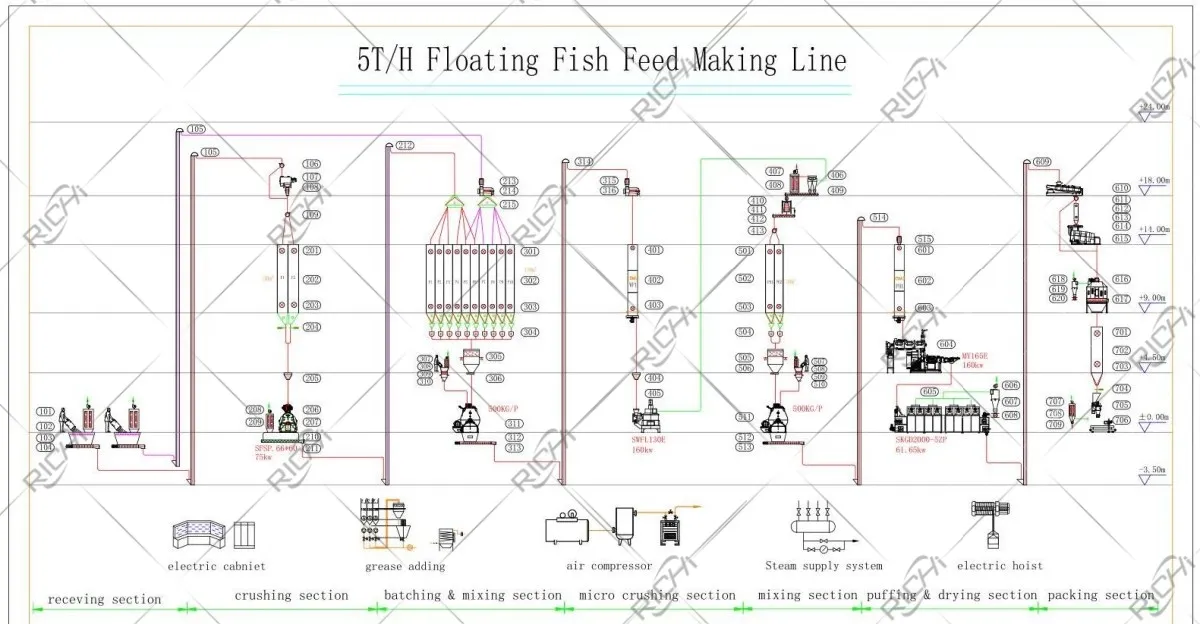

Large Capacity fish feed manufacturing unit in Vietnam

Time:2023/7

Capacity: 5T|H

Description: In 2023, a commercial aquaculture factory required a stable floating fish feed production line. After one month of communication and joint design, RICHI successfully customized a 5 T/H solution equipped with a twin-screw extrusion system. Following the installation and commissioning, the plant began operating with 10% lower energy consumption compared to the previous setups.

Typical production line parameters

| Output | 1-1.5 T/H | 1.5-2 T/H | 2-3 T/H |

| Installed Power | 200 | 300 | 400 |

| Power Consumption | 190 | 280 | 390 |

| Size | 4000x2000x4000mm | 4000x3000x4000mm | 4200x3000x4000mm |

Standard Equipment Composition

- fish feed crusher

- ultra-fine grinder

- fish feed mixer

- sinking fish feed pellet machine

- floating fish feed screw extruder

- fish feed pellet cooler

No matter your production target, we have a profession R&D team to help you choose the right fish feed manufacturing plant based on raw materials, pellet type and budget.

RICHI MACHINERY

Watch How RICHI fish feed manufacturing unit Works

Want to know how does the production line work? Watch a video about our fish feed making process. You can also check more information on our Youtube channel.

RICHI MACHINERY

Specifications to match your production goals

We offers a specification for our fish feed manufacturing plant. It’s a solutions-based approach to feed pelletizer design and manufacturing.

| Applicable Industries | Manufacturing Plant, Farms, Feed Factory, |

| Place Of Origin | China, Henan Province |

| Warranty Period | 2 Years |

| Marketing Type | New Product 2024 |

| Test Report | Provided |

| Factory Inspection | Provided |

| Warranty Period For Core Components | 2 Years |

| Core Components | PLC, Gear, Gearbox, Motor, Bearing |

| Type | Feed Pellet Machine |

| Voltage | 380V Or 415V, 3phase Voltage / Can Be Customized |

| Device Color | White And Green, Can Be Customized |

| Pelletizer Type | Horizontal Ring Die |

| Ring Die Material | Stainless Steel Ring Die |

| Finished Pellet Size | Power And 2-12mm Pellet, Can Be Customized |

| Certificates | CE, ISO, BV |

| Main Brands | Siemens Motor, SKF Bearing, Schneider Electric |

If you need help to choose the right fish feed manufacturing unit, please contact us and tell us your daily output needs, we’ll recommend the best type match to you.

How the Line Works: Workflow & Core Machine

There are multiple processes involved in a modern fish feed manufacturing plant, and to ensure the quality of the final product, each stage of the fish feed mill plant is crucial.

From raw material receiving to final packaging, we provide highly sophisticated technical support at every step, which helps make the pellets not only nutritionally balanced but also physically uniform and economically viable.

Tilapia

Trout

Catfish

Salmon

Mackerel

Goldfish

The detailed breakdown of each component in one typical fish feed manufacturing line is as follow:

1. Receiving Section

Receiving section is the first step of any fish feed making line. Whether the raw material which offer plant protein(like soybean, rapeseed meal, wheat germ meal and so on), or offer the animal protein(like fish meal, shrimp and crab meal, whey powder and so on) were all processing form here. The receiving part include the raw material delivery and screening. Efficient raw material intake system cam prevent contamination and minimize material losses.

Properly managing this step lays the foundation for the consistent quality in subsequent steps. The receiving section also includes material elevating, binning and siloing. These help organize the raw materials before they enter the next step in the production line.

2. Crushing section

Crushing section is responsible for reducing the size of raw material to a suitable range for further processing. A grinding machine or mill(typically involves hammer mills or roller mills) is used in this step. The choose of the equipment depends on the feed formulation and your desired particle size.

For fish feed, particle size can affects pellet formation. Thus thoroughly crush is very essential for high quality pellet especially for young aquatic animals. Our crushing section equipped with sieves and air separation devices to improve the grinding efficiency and minimize fines.

3. Batching & Mixing

Batching is the process of accurately measuring out raw material. The stage is crucial because it directly affects the nutritional value of the final pellet. Our batching system use PLC controls and load cells to guarantee accuracy.

Once batching is complete, the ingredients are transferred to the mixing section. Mixing is essential because it improves feed quality and ensures extruding efficiency. Moreover, the uniform blending ensures that every pellet contains balanced nutrition. Typically, the mixing section uses double-shaft paddle mixers to achieve uniformity in a short period of time.

4. Micro crushing

Micro crushing is an essential step for producing high quality aquatic feed. Small species like fry or krill require very fine particles for easy consumption and digestion. In this section, materials are further ground down to microns using fine grinders or pellet machine.

This helps to improve the pellet durability and minimize the feed waste. Micro crushing ensures that feed ingredients are small enough to pass through the pellet die holes. Thus supporting efficient pellet size during following steps like extruding or pelleting.

5. Mixing section

Mixing section is designed to incorporate vitamins, minerals, oils or other micro-ingredients into the pre prepared mix. This stage prevent the sensitive components expose to high temperatures or pressures too early during the fish feed manufacturing plant.

Fish feed mixers are used to create a uniform blend for the further pelletizing part. Proper mixing also help maintain product integrity throughout storage and transport.

6. Pelletizing & cooling

Pelletizing section is the core part of the entire production line. To begin with, let’s talk about the pelletizing process. This is the stage where the magic happens: the ground and mixed materials are formed into uniform feed pellets. In this section, the typical machines used include pellet machines (such as sinking fish feed pellet machines and floating fish feed pellet machines) as well as floating fish feed extruder machine (such as floating fish feed single-screw extruders and twin-screw extruders).

We can customized the pellet machine according to your need. After pelletizing, the feed must be cooled rapidly to remove moisture and prevent spoilage. Fish feed pellet cooler can reduce the pellet temperature thus preserving pellet strength and shelf-life.

7. Packing section

The packing section is the final step in the production line, involving the weighing, filling, sealing, and labeling of the finished fish feed. Automated packing machines ensure both speed and accuracy, minimizing manual handling while maintaining product hygiene and meeting health claims.

Properly packed products are easier to store and transport, ensuring efficiency in the supply chain.

Customized design

— Richi Machinery —

Customized solutions help different customers meet their unique business needs, improve efficiency, and reduce costs. At RICHI, therefore, all fish feed manufacturing plant are custom-designed. To achieve this, we provide tailored professional solutions based on each customer’s specific raw materials, site size and height limitations, desired automation level, and required production capacity.

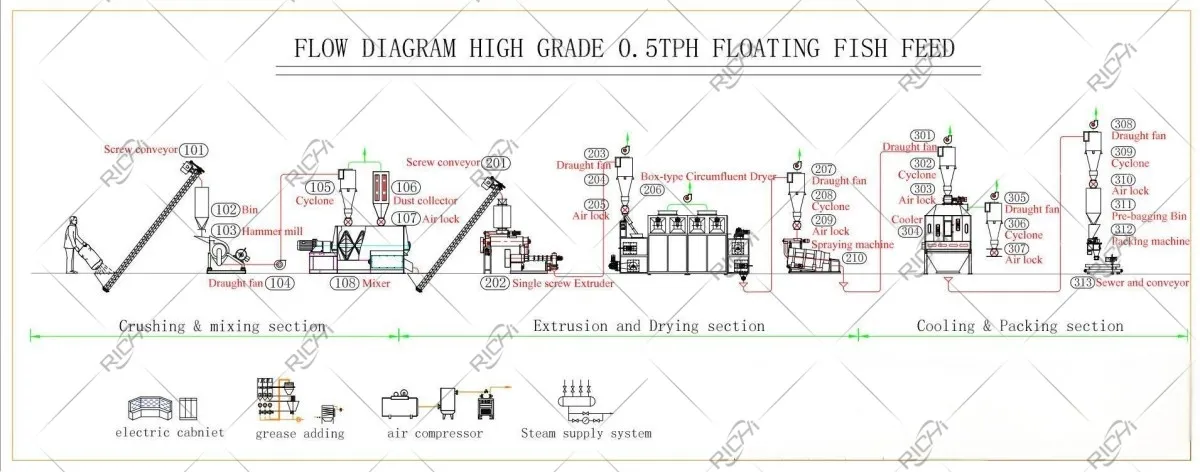

0.5 T/H Floating Fish Feed Making Line

Type of Feed Produced: Floating Feed

Process flow: Crushing system – Mixing system – Extrusion system – Drying system – Cooling system – Packaging system

Main equipment used: crusher, mixer, single screw extruder, oven, screening equipment, cooling machine, packaging equipment

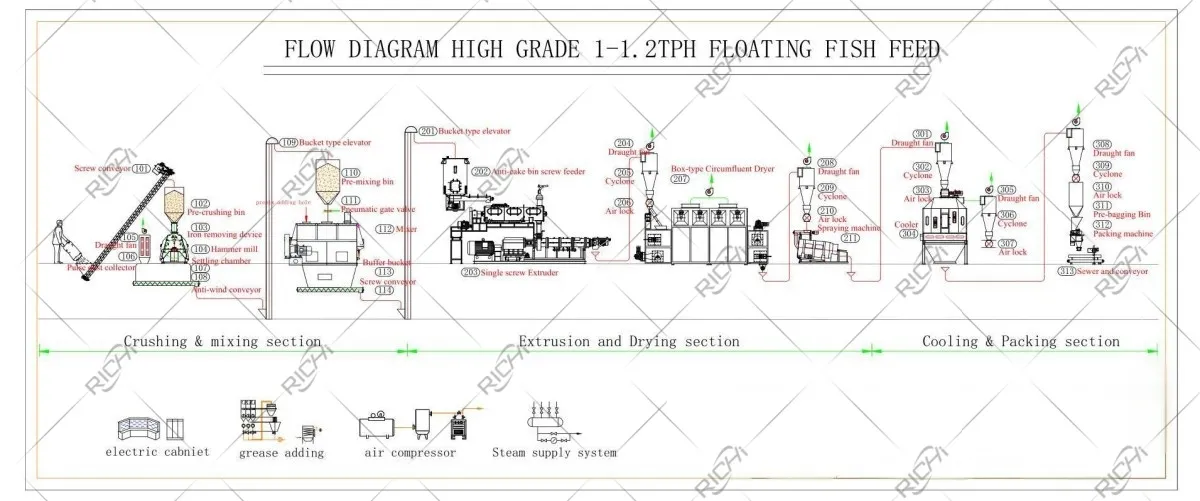

1-1.2 T/H floating fish feed manufacturing plant

Type of Feed Produced: Floating Fish Feed

Process flow: Crushing & Mixing system – Extrusion & Drying system – Cooling & Packaging system

5 T/H floating fish feed Making line

Process flow: Receiving Section – Crushing Section – Batching & Mixing Section – Micro Crushing Section – Mixing Section – Puffing & Frying Section – Packing Section

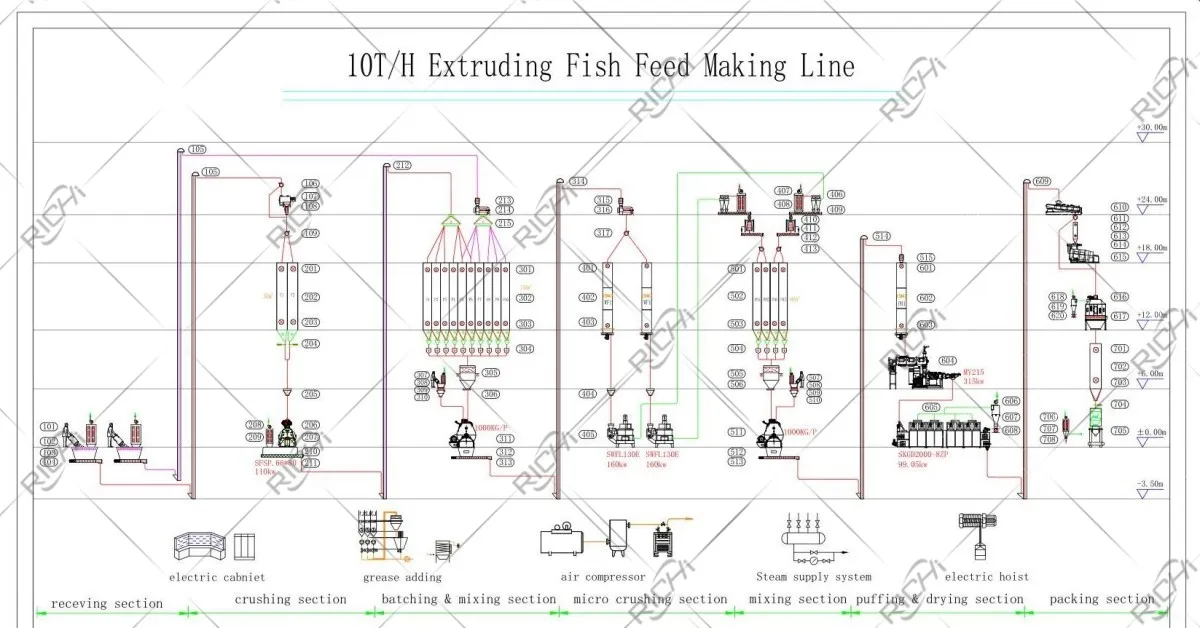

10 T/H Extruding fish feed manufacturing plant

RICHI MACHINERY

How Much Does a fish feed manufacturing plant Cost?

Different models of our production line and price range are as follow:

| Production | 1-2t/h | 3-4T/H | 5-7T/H | 8-12T/H | 15-20T/H | 20-30T/H |

| Price range | 10000-70000USD | 20000-100000USD | 30000-200000USD | 40000-300000USD | 60000-500000USD | 100000-8000000USD |

| Weight | 2-8T | 3-10T | 8-15T | 10-20T | 20-40T | 30-60T |

If you need help to start your own fish feed production plant, please contact us and tell us your daily output needs, we’ll recommend the best type match to you.

RICHI MACHINERY

Why Choose RICHI fish feed manufacturing plant

Our factory’s fish feed production plant is engineered to deliver high-quality feed. Within two decades of industry experience, we have been built an automated feed production solution. From raw material intake to final packing part all equip with the high-tech machine and best while and after service. Our outstanding cooperating features are as follow:

Comprehensive production system & high product quality

Our production line covers every critical stage in every production part to ensuring a smooth and efficient operation.

Our advanced machine guarantees stable and uniform pellet. We also have excellent water stability which is suitable for a wide range of aquatic species such as catfish, fry, shrimp and so on.

Energy efficient & cost saving

All of our equipment is designed for low energy consumption and high output, ensuring efficient and sustainable production.

As a result, we help you significantly reduce operating costs while maximizing productivity. In other words, you can achieve higher quality results with less investment, making your floating fish feed production more cost-effective and competitive in the market.

Fully customizable solutions & global project experience

We provide tailored configurations and feed formulations. All processing part and equipment can be customize according to your need. With successful installations in over 100 countries, our fish feed manufacturing plant are proven to perform in diverse environments and business scales.

Backed by over 25 years of industry experience, our team continuously upgrades technology to meet all customers’ needs.

Frequently Asked Questions-Answers to Common Queries about fish feed manufacturing plant

Customized solutions can help different customers meet their unique business needs, improve production efficiency, and reduce operational costs. That’s why all of RICHI’s fish feed manufacturing units are custom-designed to suit specific project requirements.

In addition, we offer tailored, professional fish feed processing plant solutions based on factors such as raw material types, space constraints, automation levels, and production capacity, ensuring optimal performance and long-term value.

What types of fish feed can your production line make?

Our fish feed production plant can produce floating, sinking, and slow-sinking pellets, suitable for a variety of species including tilapia, catfish, trout, and shrimp. We can customize the line based on your specific formulation and pellet size requirements.

What capacity options are available?

We offer a wide range of production capacities. From small-scale 1T/H lines to large industrial systems producing over 20 tons per hour. Our engineers will recommend the best solution based on your budget, target market, and raw materials.

Can your machine handle different raw materials?

Yes, our production line is designed to process a wide variety of ingredients, including soybean meal, fish meal, corn gluten, wheat bran, and other plant and animal protein sources.

Is the equipment easy to operate and maintain?

Absolutely. Our machines are equipped with intelligent control systems (PLC/touch screen), making them user-friendly and easy to monitor. We also provide detailed manuals and training to ensure smooth operation and maintenance.

Do you provide installation and after-sales service?

Yes. We offer full on-site installation, commissioning, and staff training. Our after-sales service team is available for remote troubleshooting, spare parts supply, and technical support worldwide.

How long does it take to set up a complete line?

Normally, it takes 30 to 60 working days for production and shipping. Installation and commissioning may take 10 to 20 days depending on the scale of the fish feed manufacturing plant and site conditions.