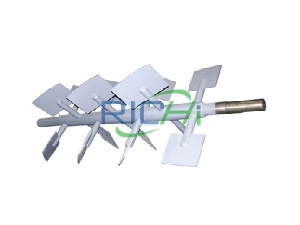

Feed mill mixer

Feed mill mixer is the key equipment in animal feed production line, specially designed to efficiently and uniformly mix various feed raw materials.

What is a feed mill mixer?

The feed mill mixer is a specialized mixing equipment designed for animal feed pellet plant, playing a significant role in the feed production line. Through its advanced mechanical structure and in accordance with scientific formulation requirements, it can thoroughly and evenly mix feed raw materials such as corn, soybean meal, and wheat bran with premixes of minerals and vitamins, ultimately producing finished feed. Through the mixing process of the feed mixer, the nutritional components of the final feed are ensured to be balanced and the quality is stable.

The quality of the feed mixer machine directly affects the nutritional value and taste of the feed. Choosing a reliable, durable and safe mixer not only enables flexible mixing of the feed, but also significantly improves production efficiency and reduces production costs.

Whether it is poultry feed, ruminant feed or aquatic feed, RICHI feed mill mixer can fully mix and meet the mixing requirements of different raw material combinations. If you need to purchase a mixing equipment or need to equip corresponding other equipment, RICHI can provide you with customized services.

RICHI MACHINERY

How does the feed mixer machine work?

The feed mill mixer is driven by mechanical power to operate the internal mixing device. During the mixing process, the mixer rotates to move the raw materials in various ways, achieving uniform dispersion and preventing agglomeration and stratification. After the mixing is completed, the materials are discharged from the outlet. The main discharge methods are manual discharge and pneumatic discharge.

The entire mixing process is controlled with reasonable time, usually completed within several minutes, ensuring that the feed is mixed evenly without damaging the raw material structure. The efficient mixing effect can ensure that the final feed meets the nutritional requirements of animals.

classification of feed mill mixer

— Richi Machinery —

Different types of feed mixers, based on their structure and mixing methods, can meet the production requirements of various scales and formulas for feed. The specifications and parameters of these not only determine the production efficiency and mixing quality, but also directly affect the energy consumption, floor space, and maintenance cost of the equipment. Below, we will list all the types of machines of RICHI Machinery and their main technical parameters to help you quickly determine which model is the most suitable for your production line.

If you need help to choose the right feed mixer machine, please contact us and tell us your needs, we’ll recommend the best type match to you.

RICHI MACHINERY

Product advantages of RICHI feed mill mixer

The RICHI Machinery feed mixer, leveraging years of industry experience and advanced manufacturing techniques, can complete high-precision mixing within a short period of time, and is compatible with various raw material forms and formula requirements. Whether it is a single-shaft paddle mixer, a double-shaft paddle mixer, a ribbon mixer, or other types of mixing equipment, we can provide customers with the most suitable solutions and achieve production automation and energy conservation.

Excellent uniformity of mixture

The RICHI feed mixer adopts advanced blade or screw structure design to ensure that the raw material pellets are evenly distributed throughout the batch. With an optimized rotor design and precisely calculated mixing angles, a complete mixing cycle only takes 1 to 5 minutes.

The coefficient of uniformity of mixture can reach ≤ 5%, avoiding feeding differences and maximizing the growth performance of animals. This high-precision mixing capability is particularly important for high-value formulas and special nutritional requirements.

Durable in structure and easy to maintain

The RICHI feed mill mixer is made of high-quality stainless steel or carbon steel and can be optionally equipped with wear-resistant or anti-corrosion coatings. The fully welded structure ensures the strength of the equipment, with smooth internal surfaces that are not prone to sticking.

Such a design significantly reduces residues, lowers the frequency of cleaning and maintenance downtime, and ensures the stable and efficient operation of your production line for many years.

Wide applicability and support for customization

Our feed mixer machine can handle various raw materials and additives with ease, and is suitable for multiple feed formulations, including poultry feed, ruminant feed, and aquatic feed.

RICHI can customize the production capacity, discharge method, liquid spraying system, and automatic control according to customer requirements, enabling the mixer to perfectly match your raw material characteristics, plant layout, and production goals.

global cases of animal feed mill mixer

— RICHI Machinery —

How to Choose the Right Feed Mill Mixer

Choosing the right feed mill mixer is crucial for ensuring feed quality, production efficiency, and long-term operating cost control. When selecting a mixer, consider the following factors.

Production Capacity

Small-scale production (≤500 kg/batch): Ribbon mixers or small single shaft paddle mixers are economical choices. Medium to large-scale production (>1 ton/batch): Single or double shaft paddle mixers are more efficient and durable.

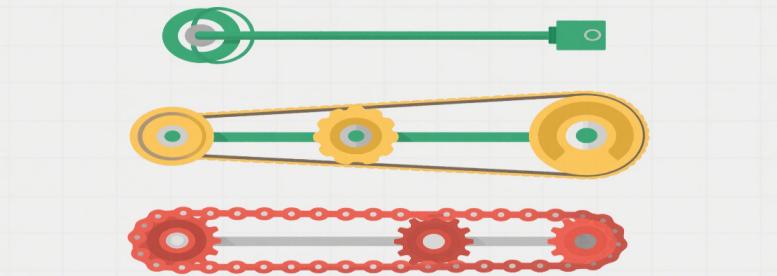

Maintenance & Operating Costs

Minimum cost: The single-axis blade mixer uses direct connection with the reducer, resulting in the lowest maintenance cost.

Medium cost: The helical mixer only requires the replacement of the belt. The probability of damage to the pulley is low.

Maximum cost: The double-axis blade mixer uses chain drive. It needs to be regularly oiled, inspected, and the chains replaced.

Mixing Time & Uniformity

Paddle mixers: 1–3 min, CV ≤ 5%, best for high-end feed lines.

Ribbon mixers: 3–5 min, slightly lower uniformity, suitable for special material differences.

Discharge Method

Manual discharge: Suitable for small capacity, lower investment.

Pneumatic discharge: Faster unloading, half-open door for 500 kg, full-open door for ≥1 ton.

Selecting the right feed mill mixer is not just about matching capacity—it’s about finding a solution that fits your production goals, raw materials, and budget for the long term.

Contact us today to get a tailored recommendation for your operation.

RICHI MACHINERY

Application of single machine in production line

In the feed production line, feed mill mixer is often located in the middle of the whole process, which connects the front end of raw material preparation and the back end of granulation and packaging.

Before mixing, we will pre-treat the raw materials. Raw materials will be cleaned and crushed to ensure that all the raw materials have the same pellet size and no impurities.

The processed material is then fed to a feed mixer for thorough mixing, which usually takes between 1 and 5 minutes, depending on the complexity of the feed formula.

After mixing, the mixture will undergo sterilization and maturation in a granulator or extruder then be extruded through a ring die to form pellets.

The newly pressed pellets need to be cooled. After cooling is complete, the finished pellets are packed and sieved, and then the production process is completed.

As an important equipment connecting raw material crushing and granulation, the performance of feed mill mixer directly affects the efficiency and product quality of the whole production line. Selecting a mixer suitable for their own production capacity and feed type can effectively ensure smooth production, improve feed uniformity and promote the healthy growth of animals.

Frequently Asked Questions

We know that choosing the right feed mill mixer and keeping it running smoothly can raise many questions. To help you make confident decisions and get the most out of your investment, we’ve compiled answers to some of the most common questions our customers ask.

What’s the difference between manual and pneumatic discharge?

Manual discharge is simple, low-cost, and works well for mixers of 500kg or less, especially when budgets are tight or when automation isn’t a priority.

Pneumatic discharge, on the other hand, is the go-to choice for mixers 1 ton and above—it opens and closes faster, reduces residue, and helps keep production lines moving. For high-volume production, pneumatic discharge often pays for itself in time saved.

How often should I maintain the mixer?

Good maintenance habits not only extend the lifespan of equipment but also ensure stable feed quality.

For chain-driven mixers, the chain condition should be checked monthly and lubricated with oil. Generally, the chain and sprocket need to be replaced every 2-3 years. For belt-driven mixers, the belt needs to be replaced irregularly, and the belt pulley is unlikely to wear out. In direct connection type, maintenance is almost negligible, but the purchase cost is higher.

Can the mixer handle liquid additives?

Yes, most mixers can be equipped with a liquid spray system, allowing the addition of oils, molasses, or other liquid nutrients during the mixing process. In practical applications, RICHI’s equipment can ensure uniform liquid distribution and prevent raw materials from clumping, which is particularly beneficial for improving the palatability and nutritional value of the feed.

How do I choose the right feed mill mixer for my production line?

When choosing the appropriate mixer, you should not only focus on the price, but also consider the production capacity, efficiency and the reliability of the equipment.

First, look at your daily production volume. If you are a large feed factory that needs continuous production and high output, a high-capacity single-axis or double-axis paddle mixer can complete the mixing within 1-3 minutes, with an evenness of CV ≤ 5%. If it is small-scale production or the raw materials in the formula have different densities and particle sizes, a helical mixer would be a more economical choice. Although the mixing time is slightly longer (3-5 minutes), it has stronger adaptability to the raw materials.

At the same time, don’t forget to consider the subsequent operation and maintenance costs. Some mixers require frequent inspections and replacement of chains or belts, while others require almost no maintenance but have a higher purchase price.

RICHI MACHINERY

WHY CHOOSE US?

Selecting the right equipment suppliers is key to achieving stable production and long-term profitability. As an industry-leading manufacturer, RICHI MACHINERY combines decades of experience, advanced technology, and a global service network to deliver equipment that meets customer needs and customizes production lines. The following three core advantages will demonstrate why thousands of global clients choose to partner with us.

Strict quality standards and rich experience

With over 20 years of experience in pellet production manufacturing, we have served thousands of customers worldwide across more than 120 countries and regions.

Our reputation stems from strict international quality standards, with all products certified by ISO, CE, SGS and other international certifications, ensuring stable performance and reliable quality.

Customized feed pellet production scheme

We customize pellet plant solution for each customer, with advanced technology and professional design services, covering the whole process support from manufacturing, delivery to installation and training.

Each solution aims to help customers achieve efficient, intelligent and sustainable production.

Comprehensive after-sales service guarantees long-term operation

Our commitment extends beyond equipment supply to include rapid response after-sales services covering everything from initial consultation to long-term maintenance.

We are dedicated to building lasting partnerships rooted in responsibility and trust. Contact us now for customized solutions and quotations that will elevate your production to new heights.