Feed Granulator Machine Price

Feed granulator machine price ranges from $7,500 to $85,000, offering efficient, durable, and high-output solutions for animal feed pellet production. Whether you operate a medium-to-large farm or a feed processing plant of any size, our advanced feed granulator machines deliver reliable performance, consistent pellet quality, and long-term value.

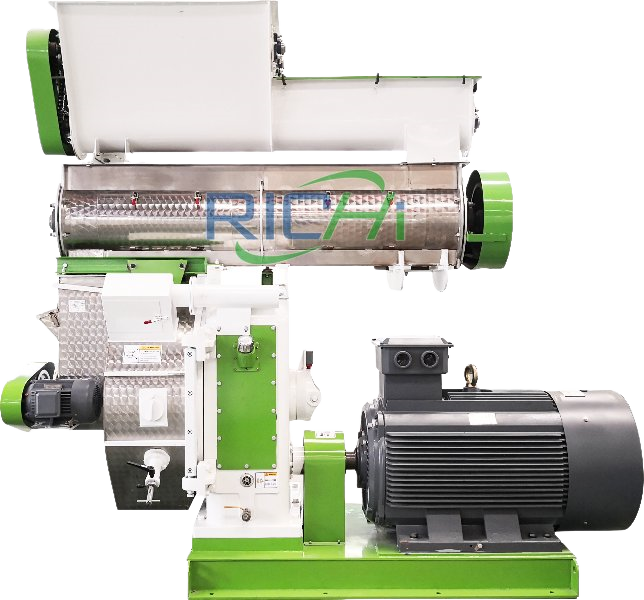

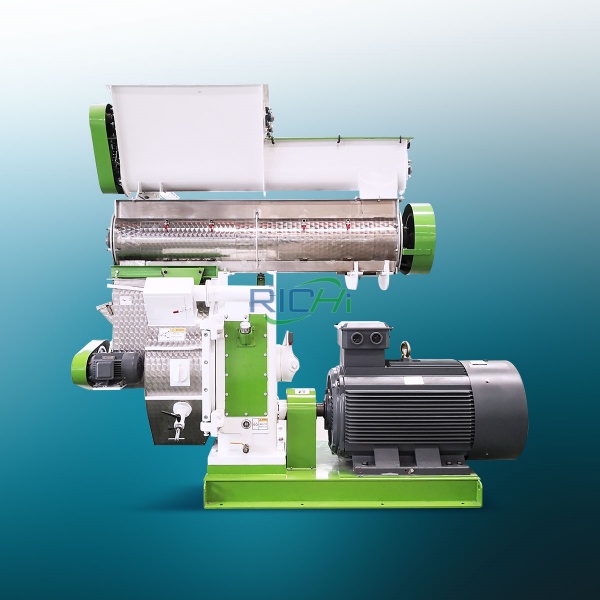

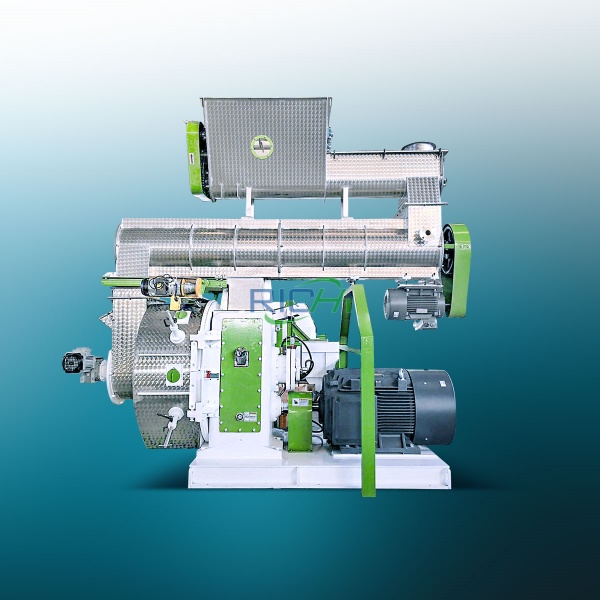

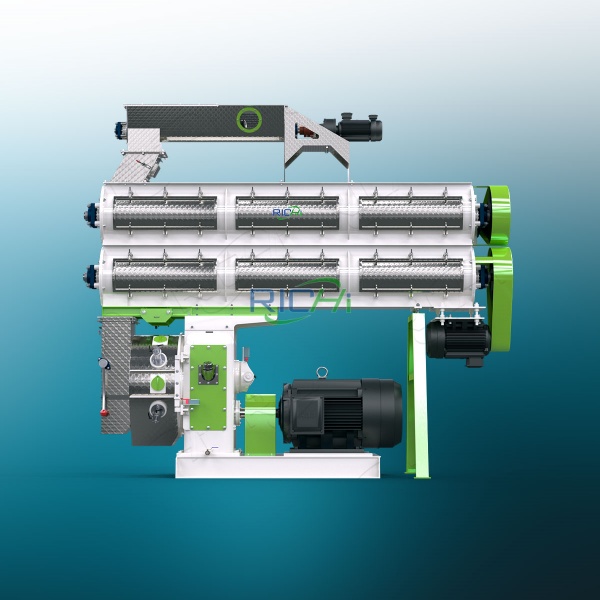

What is the Feed Granulator Machine?

A feed granulator machine is a specialized feed processing device used to compress powdered raw materials into uniform, compact, and nutrient-rich pellets, facilitating animal consumption and digestion. It is a core piece of equipment in the feed processing industry and is widely used in livestock, poultry farming, and aquaculture.

During pelleting, the mixed feed powder is fed into a conditioner for maturation and gelatinization, improving the raw material’s cohesiveness. It then enters the pelleting chamber, where pressure rollers force it into the die holes, extruding it into cylindrical pellets under high pressure. As the feed is extruded, a rotating cutter cuts it into pellets of uniform length. Pelleting improves feed utilization, reduces waste, and promotes healthy animal growth.

RICHI Machinery feed granulator machines can be customized to meet specific user needs. Pellet diameters typically range from 2 mm to 12 mm and can be adjusted based on animal species and feed formulation. With proper configuration, a single feed granulator can meet the production needs of farmers and commercial feed mills.

One of the most important factors when purchasing this type of equipment is the feed granulator machine price. Typically, the price ranges from $7,500 to $85,000, depending on production capacity, equipment configuration, and level of automation. Smaller machines are relatively simpler to configure and less expensive, suitable for start-up or low-capacity needs. Larger machines, while more expensive, offer higher efficiency and lower energy consumption for long-term stable production.

In conclusion, the feed granulator machine is not only a core piece of equipment in modern feed manufacturing but also a key investment for improving feed quality and farm profitability. Understanding feed granulator machine prices helps investors and farmers find the optimal balance between performance and budget, thereby achieving efficient and sustainable feed production.

Video of RICHI Feed Granulator Machine

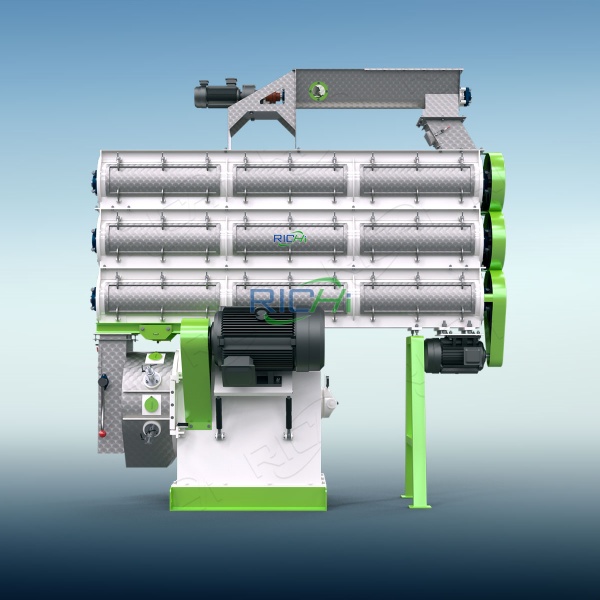

The video will visually showcase the overall design and manufacturing quality of the RICHI feed granulator machine. You can clearly see its compact layout, durable material selection, and meticulous craftsmanship details, all reflecting RICHI’s professional manufacturing capabilities and reliable performance. From structural design to manufacturing processes, every detail reflects the quality and value commensurate with our feed granulator machine price.

Different Prices Of RICHI Feed Granulator Machine For Sale

RICHI Machinery offers various models of feed granulator machines to meet the diverse production needs of investors. Each machine we sell is meticulously designed for durability, low energy consumption, and stable output. Feed granulator machine prices vary depending on production capacity, motor power, and configuration, flexibly catering to the investment budgets of medium to large-scale farms and feed mills of all sizes.

SZLH250 Feed Granulator Machine

- Production Capacity: 1-2T/H

- Main Motor Power: 22KW

- Feeder Power: 1.1KW

- Modulator Power: 1.5KW

- Ring Die Inner Diameter: 250mm

- Price: 7,000-10,000 USD

SZLH320 Animal Feed Pellet Mill

- Production Capacity: 3-4T/H

- Main Motor Power: 37KW

- Feeder Power: 1.5KW

- Modulator Power: 4KW

- Ring Die Inner Diameter: 320mm

- Price: 10,000-20,000 USD

SZLH350 Feed Granulator Machine

- Production Capacity: 5-6T/H

- Main Motor Power: 55KW

- Feeder Power: 1.5KW

- Modulator Power: 4KW

- Ring Die Inner Diameter: 350mm

- Price: 25,000-32,000 USD

SZLH420 Feed Granulator Machine

- Production Capacity: 10T/H

- Main Motor Power: 110KW

- Feeder Power: 1.5KW

- Modulator Power: 7.5KW

- Ring Die Inner Diameter: 420mm

- Price: 32,000-40,000 USD

SZLH508 Feed Granulator Machine

- Production Capacity: 15T/H

- Main Motor Power: 160KW

- Feeder Power: 1.5KW

- Modulator Power: 7.5KW

- Ring Die Inner Diameter: 508mm

- Price: 40,000-50,000 USD

SZLH558 Feed Granulator Machine

- Production Capacity: 20T/H

- Main Motor Power: 185KW

- Feeder Power: 1.5KW

- Modulator Power: 11KW

- Ring Die Inner Diameter: 558mm

- Price: 50,000-60,000 USD

SZLH678 Feed Granulator Machine

- Production Capacity: 30T/H

- Main Motor Power: 250KW

- Feeder Power: 1.5KW

- Modulator Power: 11KW

- Ring Die Inner Diameter: 673mm

- Price: 60,000-70,000 USD

SZLH768 Commercial Feed Pellet Mill

- Production Capacity: 40T/H

- Main Motor Power: 315KW

- Feeder Power: 2.2KW

- Modulator Power: 11KW

- Ring Die Inner Diameter: 762mm

- Price: 70,000-85,000 USD

While the feed granulator machine price is often the first factor customers consider when investing, the true value of the equipment goes far beyond the numbers. Before making a purchase decision, it’s essential to understand the machine’s internal design details, material selection, and manufacturing processes—factors that determine how long the machine can operate on the production line, its performance stability, and the efficiency of pellet formation. These are the reasons why RICHI feed pellet mills stand out from their competitors.

Key Structure Of Feed Granulator Machine

RICHI’s feed granulator machine features a robust and durable design, ensuring stable operation even under high loads and continuous production conditions. This is a key factor determining the machine’s durability, operational stability, pellet quality, and long-term return on investment.

While the feed granulator machine price reflects the initial equipment cost, its true value lies in details such as motor efficiency, frame strength, material selection, and transmission design. It is precisely this perfect balance between reasonable price and superior performance that makes the machine an ideal choice for investors worldwide.

Robust Body Structure

The RICHI feed granulator machine is constructed from high-strength 304 stainless steel, resulting in a robust and durable structure with excellent corrosion resistance and a long service life. It maintains stable operation even under prolonged continuous operation. Furthermore, its robust design effectively reduces vibration during operation, enhancing the stability and safety of the equipment.

Forced Feeder

For some lightweight raw materials, the forced feeding device can ensure that the raw materials enter the pelleting chamber continuously and evenly, avoiding material blockage or uneven feeding, thereby ensuring stable production process and consistent pellet quality.

Advanced Conditioning System

Depending on the characteristics of different feed ingredients, the feed granulator machine can be configured with single-layer, double-layer, or triple-layer modulators. This system thoroughly cooks and softens the ingredients, significantly improving pellet formation rate and stability while maximizing the retention of the feed’s nutritional components.

High-Precision Ring Die

The ring die is made of high-quality alloy steel and undergoes advanced processing and heat treatment, resulting in high hardness, uniform pore size, and strong wear resistance. The produced particles have uniform density, smooth surfaces, and excellent forming effect.

Efficient Motor&Transmission System

This equipment is equipped with a high-efficiency motor from the internationally renowned Siemens brand, ensuring stable operation, low energy consumption, and a long service life. The precise transmission system achieves optimal power output with minimal energy loss, thereby significantly improving production efficiency and reducing operating costs.

Intelligent Control System

The equipment is equipped with an intelligent PLC control system, allowing operators to monitor parameters such as temperature, current, and output in real time. The system features automatic alarm and protection functions, is easy to operate, safe and reliable, and effectively reduces maintenance frequency.

With its robust construction and precise design, the RICHI feed granulator machine is not only exceptionally durable but also highly adaptable. The perfect combination of a high-efficiency motor, an advanced modulation system, and a corrosion-resistant stainless steel body allows it to easily handle various feed formulations and ingredient types, consistently maintaining stable operation and uniform pellet quality.

Application Solutions for Various Needs

RICHI feed granulator machines are designed to meet diverse feed production needs, covering poultry, livestock, aquaculture, and ruminant industries. Because different feed types have varying requirements for pellet density, size, and conditioning, RICHI offers flexible configuration options, all customizable to meet specific customer needs.

These technical differences also affect the feed granulator machine price. Standard models for poultry or pig feed are more economical, while high-end models for cattle or floating fish feed production are more expensive due to the need for larger ring dies, more powerful motors, and efficient conditioning devices. This flexible pricing and configuration system allows customers of all sizes, from medium-sized to large farms and feed mills of all sizes, to choose the ideal equipment that best suits their raw material characteristics, production capacity needs, and budget.

Livestock Feed Production Line

Ruminant Feed Production Line

Different Feed Granulator Machine Price In Global Projects

When investing in feed production projects, the feed granulator machine price will vary depending on the country and the scale of the project. In fact, the cost of a pellet mill is not fixed but varies depending on the type of raw materials, power configuration, production capacity, and the type of animals being fed. This reflects not only differences in equipment specifications but also the diverse market demands and investment strategies around the world.

RICHI’s true value lies in its long-term, stable production capacity, minimal downtime, and consistent feed quality. Whether for medium- to large-scale farms or commercial feed mills of various sizes, we can provide customized pellet equipment products and pellet plant solution tailored to your specific needs, achieving the best cost-performance ratio, ensuring stable operation, and delivering a high return on investment.

Feed Granulator Machine For Sale Malaysia

- Project Output: 2T/H

- Raw Materials: Corn 50%, Soybean meal 25%, Wheat bran 18%, Rice bran 7%

- Feed Granulator Machine Price: About 7,000 USD

- Project Background: The customer required a compact chicken feed production line with a capacity of 2–3 tons/hour, primarily for producing feed for broilers and laying hens. RICHI provided a fully configured feed granulator machine and auxiliary equipment, adapted to tropical environments, ensuring stable operation and uniform pellet production.

Feed Granulator Machine In Australia

- Project Output: 3T/H

- Raw Materials: Barley 40%, Wheat 30%, Canola meal 20%, Fish meal 10%

- Feed Granulator Machine Price: About 12,000 USD

- Project Background: The client invested in a small livestock farm in Australia, producing feed for chickens and pigs. They needed a pellet mill with a capacity of 3 tons per hour, capable of processing a variety of feed ingredients and producing balanced pellets suitable for different animals. RICHI designed the entire poultry feed pellet plant based on local nutritional standards and operational requirements.

Feed Granulator Machine For Sale Uzbekistan

- Project Output: 5T/H

- Raw Materials: Corn gluten 40%, Wheat flour 25%, Soybean meal 25%, Fish oil 10%

- Feed Granulator Machine Price: About 26,500 USD

- Project Background: The client is a commercial fish farm in Uzbekistan, primarily farming catfish and carp. They needed a sinking fish feed production line with a capacity of 5 tons/hour. RICHI customized the equipment to suit the local water conditions, ensuring the production of uniformly sized, consistently dense, and nutritionally rich floating fish feed pellets.

Feed Granulator Machine For Sale Afghanistan

- Project Output: 10T/H

- Raw Materials: Barley 35%, Maize 35%, Soybean meal 20%, Wheat bran 10%

- Feed Granulator Machine Price: About 30,000 USD

- Project Background: The client is a large-scale farm in Afghanistan that raises chickens and sheep. They needed a pellet mill with a capacity of 10 tons per hour, capable of producing feed pellets for both poultry and livestock simultaneously. RICHI provided a turnkey solution for their animal feed mill plant, ensuring uniform pellets, reliable equipment operation, and high-efficiency production.

Why Choose Our Feed Granulator Machine

When choosing feed processing equipment, many investors not only focus on product quality and performance but also place great importance on balancing the price of a feed granulator machine with long-term return on investment. RICHI feed granulators ensure an optimal balance between economy and reliability. Whether building a small feed mill or expanding a large industrial production line, our equipment guarantees stable output, low maintenance costs, and high efficiency. It is this combination of durability, precision, and cost-effectiveness that makes RICHI equipment the preferred choice for customers worldwide.

High Cost Performance With Reliable Quality

The RICHI feed granulator machine is constructed from high-grade stainless steel and features a precision mechanical structure, ensuring long-term stable operation. Through optimized transmission systems and energy-saving design, users can significantly increase output while reducing energy consumption.

Our equipment offers superior performance at a reasonable price, providing investors with long-term value far exceeding the purchase cost.

Comply With International Standards

All equipment complies with international standards such as ISO, CE, SGS, and BV. The voltage, motor configuration, and control system of the equipment can be flexibly customized according to national standards, ensuring smooth installation and safe operation.

This rigorous international standard system ensures that every piece of our equipment maintains stable and reliable performance regardless of the region or scale of the production environment.

Trusted By Customers In 140+ Countries

Currently, RICHI feed pellet mills are successfully operating in over 140 countries worldwide, demonstrating excellent stability and adaptability in various environments, from poultry feed to aquatic feed. Each success story reflects our commitment to reliable technology and efficient service.

The long-term trust from our global customers proves that RICHI is not only an equipment supplier, but also a global partner for the sustainable development of the feed industry.

Choosing the right equipment involves more than just price considerations; it’s about long-term performance, efficiency, and reliability. Leveraging extensive experience in feed engineering and a global portfolio of installation projects, RICHI Machinery turnkey service provides clients with complete solutions, from process design and equipment manufacturing to installation, commissioning, training, and after-sales support, ensuring maximum value for our customers.

FAQ

To help you make a more informed investment decision, we’ve compiled a list of frequently asked questions from customers around the world. These answers will help you gain a more comprehensive understanding of feed granulator machine price.

I have about 4,000 dairy cows. What capacity of feed granulator machine do I need, and what’s the price range?

+

For a farm with 4,000 dairy cows, the daily feed requirement can be estimated at 6 kg per cow, totaling 4,000 × 6 kg = 24,000 kg, or 24 tons. Based on the production plan, if operating for 6-8 hours per day, the required hourly capacity is 3-4 tons/hour. The RICHI SZLH320 model has a capacity of 3-4 tons/hour, making it ideal for your farm. This feed granulator machine is priced between $10,000 and $20,000.

You can also choose to configure it with a grinder, mixer, conveyor, cooling, and screening system to effectively ensure smooth production line operation and produce high-quality feed pellets.

My raw materials are corn, soybean meal, and wheat bran. Can one machine handle them all?

+

Yes, our RICHI feed granulator machine efficiently processes a variety of feedstocks, including corn, soybean meal, and wheat bran, ensuring a stable production of uniform, high-quality pellets from a single unit. For lighter feedstocks like soybean meal or some wheat bran, we add a forced feeder to ensure smooth feeding into the pellet mill, preventing blockages and maintaining consistent pellet uniformity throughout the production process.

Our equipment is fully configured, reliable, and durable. The feed granulator machine price reflects the high quality of this complete system, providing farms with a high-performance and cost-effective solution.

I want to produce feed for both chickens and fish. Do I need two machines?

+

If your plan is to produce both floating fish feed and poultry feed simultaneously, we generally recommend two separate production lines. This is because floating aquatic feeds typically require an extrusion process to ensure the pellets float, while poultry feed is generally produced using a pelleting method. Using separate production lines ensures that the quality of each feed meets requirements and does not affect the others.

However, if you primarily produce sinking fish feed or general livestock feed, a single RICHI feed pellet mill can efficiently handle both purposes. With the addition of a conditioner and adjustable ring die, the equipment can adapt to different formulations and pellet sizes. This flexibility allows you to produce high-quality feed for a variety of animals without adding production lines, making it ideal for farms with limited space or budgets.

With reliable performance, durable construction, and the ability to adapt to different formulations, our equipment offers excellent value for money. The price of our feed granulator machine matches its performance, providing an efficient and economical solution for feed production for a wide range of animals.

What kind of after-sales support do you provide?

+

RICHI provides comprehensive after-sales support for all its equipment, ensuring smooth and efficient operation throughout its entire lifespan. Our services include installation and commissioning guidance, operator training to ensure correct operation, remote troubleshooting for rapid resolution of technical issues, and timely provision of genuine spare parts when needed. Furthermore, we offer maintenance advice and operating instructions to help users extend equipment lifespan and improve productivity.

The feed granulator machine price reflects not only the equipment’s reliable performance and durable design but also the value of comprehensive after-sales support. Choosing RICHI provides you with a high-quality, worry-free solution, allowing you to focus on efficient feed production without concerns about downtime or technical issues.