1-2 T/H Chicken Feed Production Line in Tanzania

The 1-2 T/H chicken feed production line in Tanzania processes corn and wheat into high protein nutrition.

Project Overview

RICHI Manufacture has started to build a prospect of chicken feed production line in Tanzania in July, 2024. The client satisfied our professional team and in expect for the next cooperation.

1- 2

Production (ton/hour)

1- 6

Pellet size (mm)

- Project Country: Tanzania

- Project Name: Chicken Feed Production Line

- Production Capacity: 1–2 tons per hour (T/H)

- Client’s Raw Materials: Corn, wheat, soybean meal, etc.

- Final Products & Sizes: 1 – 6 mm poultry feed pellets

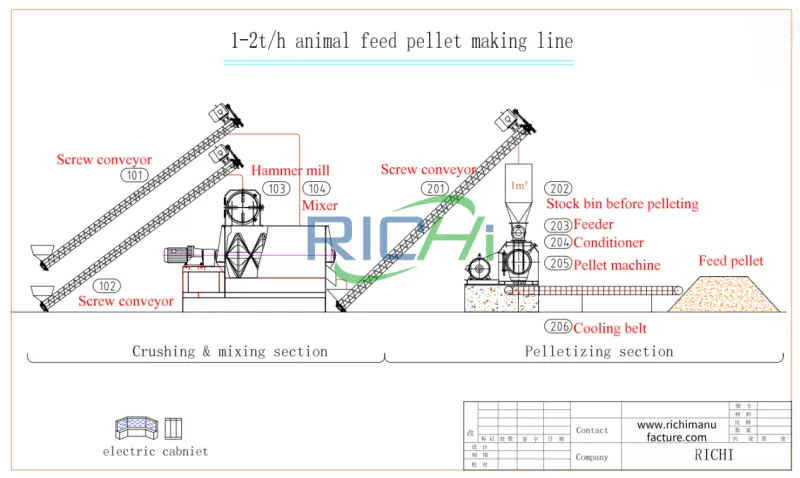

- Main Equipment: Screw conveyor, hammer mill, mixer, pellet machine, cooling belt

- Project Start Date: July 11, 2024

- Installation Period: 10 days

- Number of Engineers for Installation Support: 2 engineers

- Client’s Factory/Workshop: Existing facility available

- Our project area: 6*4*4.5 meters

- Power Consumption: 47.95 kW/H

- Operating Manpower Required: 2 people

Client Background & Challenges of building 1-2 T/H Chicken Feed Production Line in Tanzania

The client is a medium-sized poultry farmer located in Tanzania who has long relied on purchasing commercially available chicken feed. Because of the rising feed prices and fluctuating quality, they were under tremendous pressure. Two of the main issues were controlling costs while safeguarding the bird health. When firstly communicate with the client, they claimed that local supply was unstable. Meanwhile, the imported feeds had the problem of poor freshness and difficulty in customization.

Although the client has various local raw material on hand, such as corn, soybean meal and wheat, it lacks specialized equipment and technology for efficient processing. Under this background, they urgently needed a compact and energy efficient chicken feed production line. This would free them from their dependence on external suppliers, while at the same time producing high quality pellets ranging from 1.5mm to 4 mm for different bird stages.

The client’s biggest challenge was to find a cost effective turnkey solution that would not interfere with the daily farming routine.

Tailored Solution & Equipment Layout for 1-2 T/H Chicken Feed Production Line in Tanzania

In order to meet client’s chicken feed requirement and further further solve the producing challenge, we customized an 1-2 T/H chicken feed production line in Tanzania. The solutions and equipment layouts we offer to our clients are shown below:

1. Material Conveying & Adaptability Design:

The raw materials has large particle size and heterogeneity, so we choose a screw conveyor for material conveying in our design.

- Screw Conveyor: This machine conveys corn and wheat efficiently and uniformly by means of rotating screw blades that propel the material. Due to its enclosed design, material losses are minimized and a steady flow is maintained.

2. Fine Crushing Design:

After being conveyed through the auger, the material enters the Hammer Mill for refinement. Corn and wheat particles need to be crushed in order to evenly mix and granulation.

- Feed Hammer mill: We have selected a highly efficient pulverizer that can uniformly pulverize corn, wheat and other raw materials to ensure that the particles reach a standard fineness.

3. Mixing and Pelletizing:

In order to increase production efficiency and produce granules of various sizes, we have selected customized mixers and granulators for our clients.

- Mixer: The advanced V-shaped mixing design of the animal feed mixer ensures that the raw materials are fully mixed in a short period of time.

- Pellet Machine: The SZLH-320 animal feed pellet press is used to produce pellets with diameters ranging from 1mm to 6mm to meet the needs of different poultry.

4. Cooling:

After pelletizing, the feed pellets must be cooled to reduce the temperature and enhance the firmness of the pellets. A Cooling Belt is installed in the production line to quickly reduce the temperature of the pellets to room temperature.

- Cooling Belt: Through air circulation, it ensures that the heat and moisture of the pellets are quickly removed, so that the feed maintains good stability and quality before packaging.

5. Layout & Space Utilization:

The layout of the entire line is very compact, with the equipment occupying an area of only 6m x 4m x 4.5m. This is perfectly adapted to the client’s existing plant space requirements.

By arranging the equipment in a reasonable way, we ensure that the production line can maximize the use of space.

6. Data monitoring:

We also equip the production line with an automated control system, which allows the client to monitor every step of the production process in real time. This further ensures a smooth production process.

1-2 T/H Chicken Feed Production Line in Tanzania video. Check more information on our youtube channel.

Process Design for the 1-2 T/H Chicken Feed Production Line in Tanzania

The whole project include crushing & mixing section, pelletizing, cooling and packaging section. The complete animal feed processing plant flow chart is as shown below:

Installation & Problem Solving

For the 1-2 T/H chicken feed production line in Tanzania, our engineer team completed the installation of the entire production line within 10 days. During the installation process, the team strictly followed the design drawings and procedures. This ensured that each piece of equipment was installed accurately and in accordance with safety standards. We also had many conversations with the client to ensure that the operators understood how the equipment would be used.

The biggest challenge encountered during the installation was power supply issues. In response to these issues, we quickly adjusted equipment parameters and system configurations, and optimized power distribution. Finally, the poultry feed pellet plant was able to run smoothly. Through remote online technical support and on-site training, the client successfully mastered the operation and maintenance of the equipment.

Client Feedback & Future Plan

After the completion of the 1-2 T/H chicken feed production line in Tanzania, our client highly evaluated our service and equipment quality. Through communication and feedback with our clients, we are able to further optimize our equipment and services to meet their specific needs.

The project manager of the chicken feed production line in Tanzania said:

“Working with your company went very well. After the production line has been put into operation, the efficiency has been greatly improved and the quality of the feed has been well received by our clients. Thank you very much for the technical support provided by your company, we are very satisfied and hope to continue to cooperate and add more equipment in the future.”

With the chicken feed production line in Tanzania running smoothly, our relationship with the client has been further strengthened. Moreover, they have expressed their expectations for continued cooperation in the future.

Market Outlook: Chicken Feed Industry in Tanzania

As an important agricultural country in East Africa, Tanzania has seen rapid development of the livestock industry in recent years. Among them, the poultry farming industry have made a remarkable growth. With the advancement of urbanization and the policy support, the demand for poultry products such as eggs and chicken meat has been increasing. Thus further driving the rapid expansion of the chicken feed industry.

At present, the chicken feed market in Tanzania is still developing. There are several development potentials as follows:

Growing Market Demand:

The demand for poultry meat and eggs in Tanzania is rapidly increasing. Data shows that, in 2024, there are 132,000 tons of poultry meant and 6.41 billion eggs production. As a result, this demand is driving the need for high quality feed pellets for the growing market.

Sufficient Supply of Raw Materials:

According to the government agricultural data reporting in 2024, local corn production has been steadily increasing and is expected to reach 11.7 million tons in 2025. Thus providing a stable and low-cost raw material for feed pellet production.

Government Policy Support:

According to the Tanzania Investment Center (TIC), investors in the agricultural sector are entitled to tax incentives such as exemptions from import duties and 100% capital allowances. This significantly reduces initial investment and operating costs.

Regional Market Expansion Opportunities:

In addition to the local market, there is an increasing demand for high quality feed pellets in East African countries(e.g., Kenya, Uganda). Therefore, investing in a feed production line allows for export expansion and increased revenue streams.

Start Your Chicken Feed Production Journey

With our customized solutions and high-efficiency equipment, you, too, can solve the challenges of feed production and significantly increase production efficiency, just like the chicken feed production line in Tanzania we designed for our client. Whether it’s ingredient suitability, equipment optimization, or overall line layout, we have the right solution for your needs.

If you’re ready to take the first step on your own poultry feed pellet plant, contact our team of experts for personalized advice and a quote. We’ll be there to support you throughout the entire process, ensuring that your project moves forward smoothly and delivers long-term benefits.

Contact us today to start your feed production line project.