Chicken Feed Making Machine Price

Chicken feed making machine price ranges from USD 10,000 to 2,800,000, depending on the machine’s capacity and configuration. Designed for efficient and stable chicken feed production, this series of equipment is suitable for medium- to large-scale farms and feed mills of all sizes, offering advantages such as low energy consumption, reliable performance, and high economic returns.

What is the Chicken Feed Making Machine?

A chicken feed pelletizing machine is a set of equipment specifically designed for the efficient and stable production of high-quality chicken feed pellets. It processes a variety of raw materials, such as corn, soybean meal, and wheat bran, into uniform pellets suitable for different stages of poultry production, including broilers, layers, and breeders.

It includes multiple key processes, including grinding, mixing, pelleting, cooling, and packaging. Each step is carefully designed and strictly controlled to ensure high-quality and nutritionally balanced feed pellets.

- During the grinding stage, raw materials such as corn, soybean meal, and wheat bran are ground to a uniform fineness, providing an ideal foundation for subsequent mixing.

- The mixing stage ensures a fully and even distribution of various nutrients through efficient mixing, ensuring consistent feed formulation.

- During the pelleting process, the conditioned material is pressed under high temperature and pressure to form compact pellets with excellent palatability.

- The cooling stage rapidly reduces the high temperature of freshly produced pellets, preventing deformation and mold.

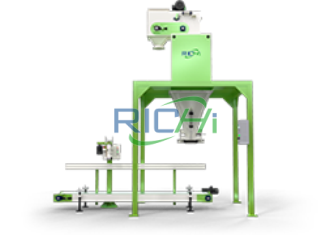

- The final packaging stage utilizes an automatic weighing system to ensure optimal feed pellet quality during storage and transportation.

The entire production process not only ensures that each feed pellet possesses high nutritional value and excellent physical properties, but also effectively improves the health and growth of chickens, thereby achieving higher production efficiency and economic benefits.

Chicken feed making machine prices vary depending on the machine’s capacity, motor power, and degree of automation. Smaller models have lower output and are relatively inexpensive, while larger industrial models can produce up to 40 tons per hour and are generally more expensive.

Overall, investing in the chicken feed making machine can achieve long-term cost savings, resulting in higher economic returns through efficient pelleting, reduced labor input, and improved poultry farming efficiency.

Video Showcase of Chicken Feed Making Machine

To give you a more intuitive understanding of the equipment’s performance, we’ve created this video. It showcases the entire chicken feed production process, from raw material crushing and mixing to pelleting, cooling and screening, and packaging. Finally, it shows chickens consuming the pelleted feed, fully demonstrating the high quality and palatability of the pellets. This real production picture not only demonstrates the efficient and stable operation of the equipment, but also intuitively illustrates the balance between performance and return on investment of RICHI chicken feed making machine price.

Different Prices Of RICHI Chicken Feed Making Machine For Sale

A complete chicken feed production line typically consists of key equipment such as a hammer mill, mixer, granulator, cooler, screener, and packaging system. Each process plays a vital role in ensuring feed pellet quality, improving production efficiency, and stabilizing pellet specifications. RICHI offers customized equipment packages with various models and production capacities to meet diverse customer needs and budgets. Below is a list of RICHI chicken feed making machine prices to help you select the most cost-effective and reliable feed production equipment configuration.

Chicken Feed Pellet Machine

Price: 7,000-85,000 USD

Vibrating screen

Price: 2,000-10,000 USD

Technological characteristics Of Chicken Feed Making Machine

When evaluating the chicken feed making machine price, it’s important to understand that the price reflects not only the machine’s capacity but also the advanced technology incorporated into it. At RICHI Machinery, each of our machines utilizes cutting-edge technology designed to ensure long-term efficient operation, exceptional durability, and precise feed production performance. These technological upgrades are what make our equipment an exceptional value.

Different Chicken Feed Making Machine Price In Global Projects

Chicken feed making machine prices vary significantly worldwide due to differences in production capacity, equipment configuration, degree of automation, and local market conditions. Each RICHI Machinery project fully demonstrates the close connection between price and performance, technology, and long-term reliability, providing valuable reference for customers planning to invest in poultry feed equipment.

RICHI Machinery has over 30 years of experience in equipment manufacturing, with projects spanning over 140 countries and regions worldwide. Whether for medium- to large-scale farms or commercial feed mills of various sizes, we can provide customized pellet equipment products and pellet plant solution tailored to your specific needs, achieving the best cost-performance ratio, ensuring stable operation, and delivering a high return on investment.

chicken feed pellet machine for sale uzbekistan

- Project Name: Chicken Feed Production Plant in uzbekistan

- Project Country: Uzbekistan

- Project Output: 5-6T/H

- Raw Materials: Maize, wheat bran, cottonseed meal, fish meal, bone meal, salt, and vitamin-mineral premixes

- Chicken Feed Making Machine Price: About 100,000 USD

chicken feed making machine for sale Angola

- Project Name: 1-2T/H chicken feed production line in angola

- Project country: Angola

- Project output: 1-2T/H

- Raw materials: Maize, soybean meal, wheat bran, fish meal, bone meal, salt, and vitamin-mineral premixes

- Chicken Feed Making Machine price: About 30,000 USD

Poultry feed making machine for Chicken in poland

- Project Name: Small-Scale poultry Feed Plant in poland

- Project Country: Poland

- Project Output: 3T/H

- Raw Materials: Maize, barley, soybean meal, rapeseed meal, fish meal, and vitamin-mineral premixes

- Poultry Feed Machine Price: About 65,000 USD

chicken feed pellet machine for sale afghanistan

- Project Name: Automatic Chicken Feed Production Line in Afghanistan

- Project Country: Afghanistan

- Project Output: 10T/H

- Raw Materials: Maize, wheat, soybean meal, sunflower meal, fish meal, bone meal, and premixes

- Chicken Feed Making Machine Price: About 180,000 USD

Why Choose Our Chicken Feed Making Machine

Choosing the right machine is key to achieving efficient, stable, and profitable chicken feed production. With advanced engineering technology, extensive global project experience, and high-quality materials, RICHI Machinery ensures that each machine delivers superior performance and long-term stability.

Global Experience and Proven Quality

RICHI has feed production projects in over 140 countries and regions worldwide, demonstrating a deep understanding of diverse formulas, raw materials, and market demands. Each unit utilizes high-quality materials, automated technology, and rigorous quality control, and is internationally certified to ensure stable production and long-lasting performance.

Tailored Design for Your Specific Needs

Whether you operate a medium- to large-scale family farm or a commercial feed mill of any size, RICHI offers animal feed pellet machine for sale tailored to your production scale, plant layout, and budget. From raw material processing to finished product packaging, every step is scientifically optimized to maximize production efficiency and feed quality.

Competitive Price with Long-Term Value

RICHI offers the most cost-effective chicken feed making machine on the market, maintaining high performance while maintaining economic efficiency. Its low energy consumption, easy maintenance, and high production capacity allow customers to achieve a rapid return on investment, and achieve long-term profitability.

In addition to providing high-quality equipment, RICHI Machinery turnkey service is customized according to customer needs to ensure that users can smoothly start feed production and achieve long-term profitability.

FAQ

When it comes to chicken feed making machine prices, customers often have many questions, such as what factors affect the price, how to choose the right configuration, and so on. To help you make an informed choice, we have compiled some frequently asked questions about RICHI feed making equipment.

What is the chicken feed making machine price?

+

Chicken feed machine price price refers to the total cost of the entire feed processing system, not just a pellet mill. The specific price varies depending on production volume, degree of automation, and configuration options. For example, a small chicken feed production line may require less configuration, sometimes requiring only a pellet mill, and is generally less expensive. Meanwhile, a large commercial feed mill with a fully automated control system and complete production process can cost upwards of $1,100,000.

RICHI offers flexible customization based on our customers’ specific needs, ensuring each piece of equipment is perfectly matched to your production goals, recipe requirements, and budget. Our engineering team will also design the most cost-effective solution for you, ensuring maximum output and optimal returns without sacrificing investment.

How do I choose the most suitable chicken feed making machine within my budget?

+

Choosing the right chicken feed making machine isn’t just about price; it’s more about balancing your budget, production capacity requirements, equipment quality, and long-term operating costs. Here are four key steps to help you choose the best equipment within your budget:

- Determine Your Production Capacity Needs

Before purchasing, determine how much feed you need to produce per hour or per day. RICHI offers equipment with capacities ranging from 1-2 tons/hour to 60 tons/hour or more for medium- to large-scale farms and feed mills of all sizes. Choosing a model that matches your scale can help you avoid wasted investment and insufficient production capacity. - Check Ingredient Compatibility and Feed Type

Different ingredients (such as corn, soybean meal, bran, or rice hulls) have different processing characteristics. You also need to consider the target feed species—broilers, layers, or breeders—as these species require different pellet sizes and formulations. Choosing equipment that matches the feed formulation ensures pellet quality and nutritional balance. - Consider the total cost of ownership of the equipment, not just the purchase price.

Chicken feed making machine price is only part of the investment. Energy consumption, maintenance frequency, parts availability, and labor costs all impact long-term profitability. Choosing equipment from a reputable brand with stable performance, even at a slightly higher price, can significantly save costs and reduce downtime later on. - Choose a manufacturer with a strong reputation and comprehensive after-sales support.

Choosing a reliable supplier can provide installation guidance, parts supply, operator training, and lifetime technical support, ensuring long-term stable operation and a higher return on investment. While some equipment may be inexpensive at the time of investment, it may face quality issues and high maintenance costs later on.

By following the above steps, you will be able to select the most cost-effective chicken feed making machine that meets your current production needs while accommodating future expansion, achieving the perfect balance between quality and price.

Can an chicken feed making machine also produce feed for Other animals?

+

Typically, chicken feed making machines are primarily used for poultry feed production and cannot be directly adapted to produce all types of animal feed. This is because different animal feed formulations, raw material characteristics, and processing requirements vary.

For example, cattle, sheep, and aquaculture feeds often contain high-fiber, high-protein, or high-fat ingredients, requiring different conditioning temperatures, moisture ratios, and pressure parameters during pelleting. Using the chicken feed making machine directly may result in poor pellet formation or nutritional imbalances.

While the chicken feed making machine can technically be used to produce other animal feeds, scientific process adjustments and appropriate equipment configuration are required. By configuring the appropriate number of conditioner stages and ring die specifications, the same production line can flexibly accommodate the production of different animal feeds without compromising pellet quality or nutritional balance.

I have 100,000 broilers and want to produce feed for them myself. What capacity and configuration should I choose?

+

100,000 broiler chickens require approximately 12 tons of feed per day. If you plan to produce feed for 6–8 hours daily, you will need a production capacity of 1.5–2 T/H to meet your flock’s needs efficiently. For this lower production capacity, we recommend a pellet mill with a capacity of 1–2 tons/hour (such as the RICHI SZLH250) or a small production line. The basic chicken feed making machine price is about $7,500, and the price may be higher if other auxiliary equipment is required.

If I want the machine with 3T/H capacity, how much does it cost?

+

The 3-ton/hour poultry feed making machine price for chicken depends primarily on the configuration you require.

If your raw materials are already in powdered form and require only pelleting (meaning, only a chicken feed pelletizer is needed, not including the crushing, mixing, cooling, and packaging components), the price includes only the pelletizer itself, typically between $10,000 and $20,000.

However, if you require a complete system, including a crusher, mixer, pelletizer, cooler, screener, and packaging machine, the investment will be higher. In this case, the complete chicken feed making machine price typically ranges from $60,000 to $200,000, depending on the level of automation, equipment materials, and overall configuration.