Cattle Feed Pellet Mill For Sale

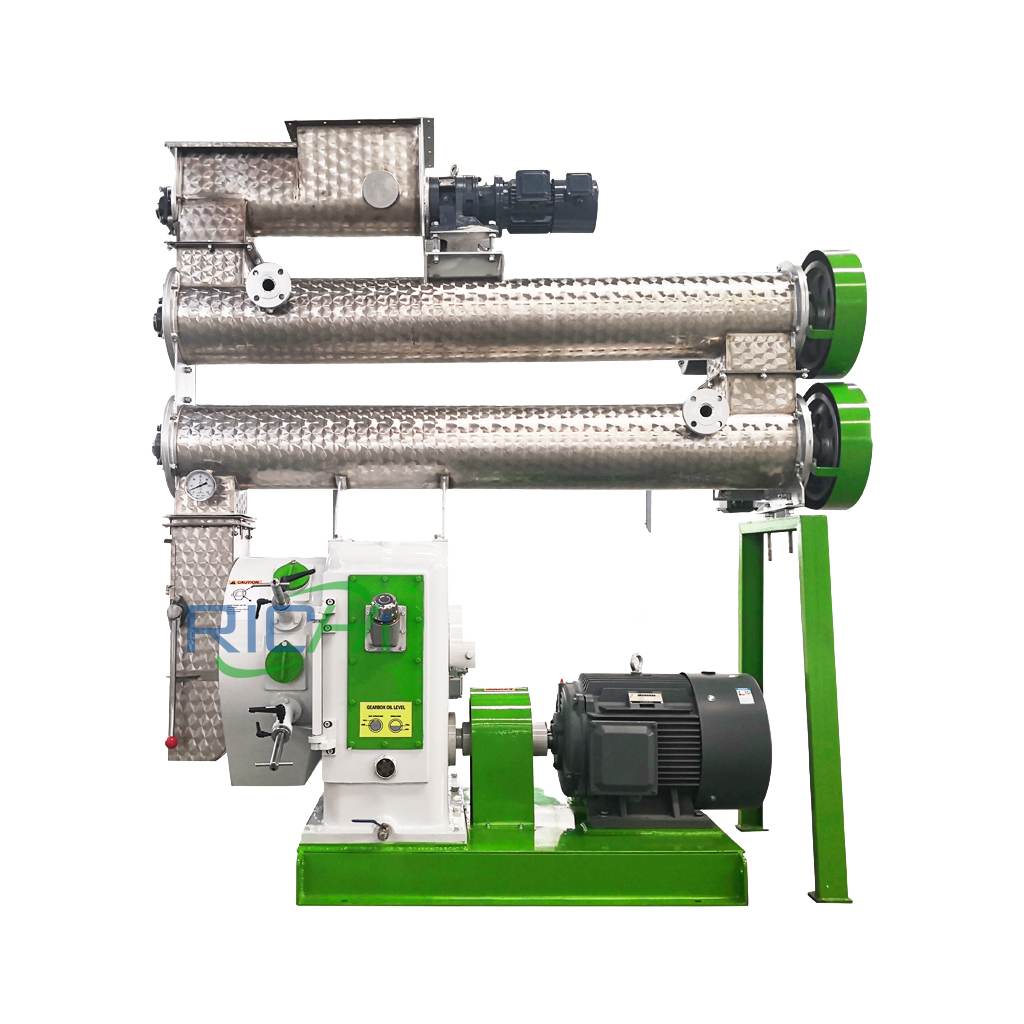

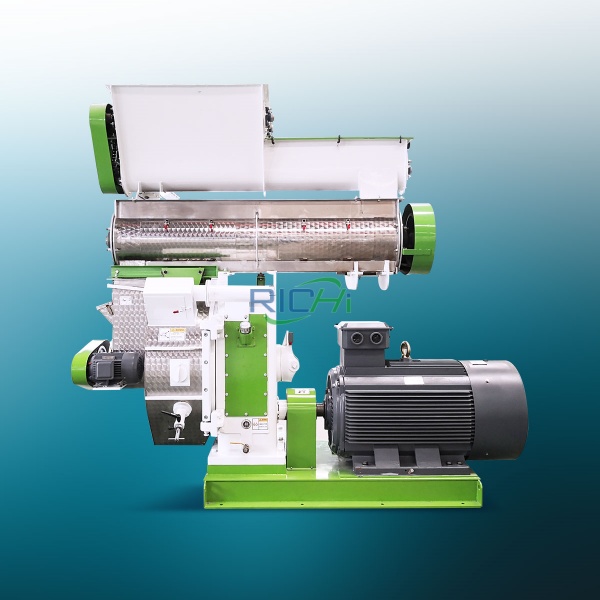

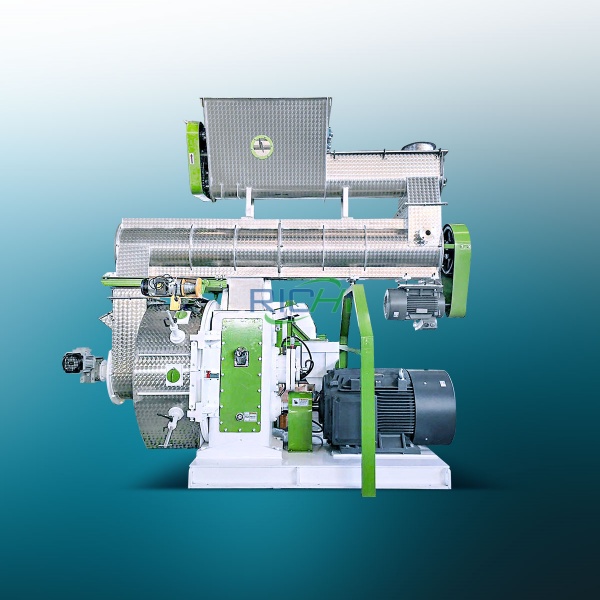

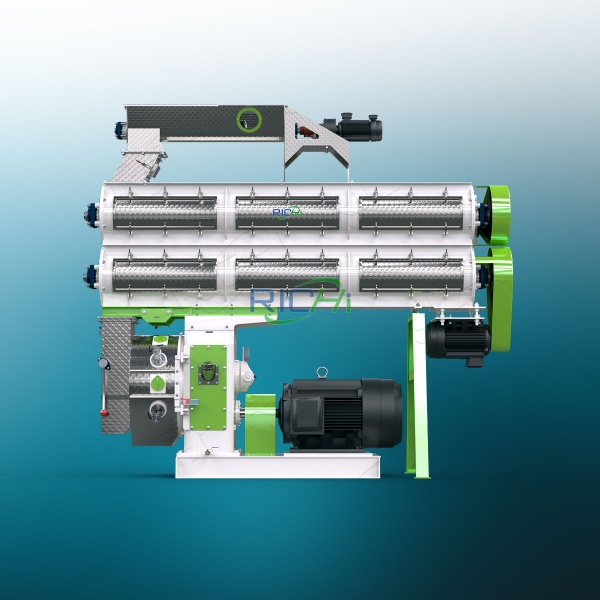

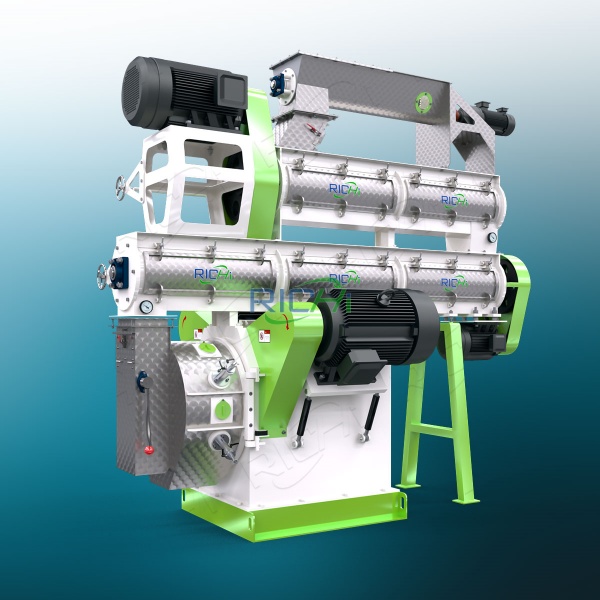

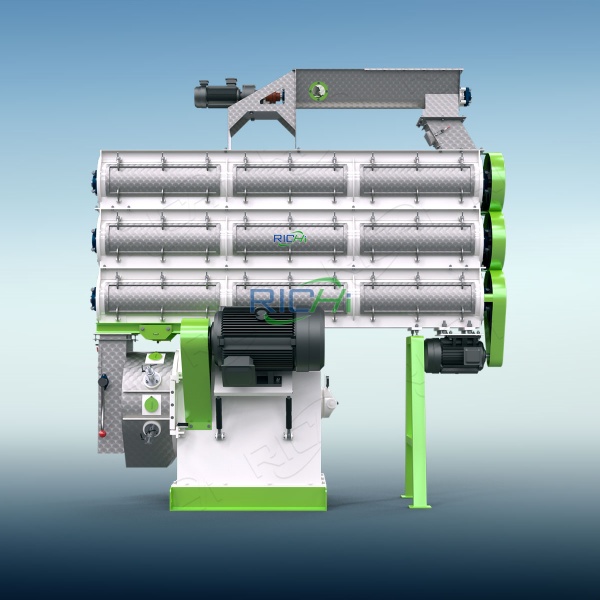

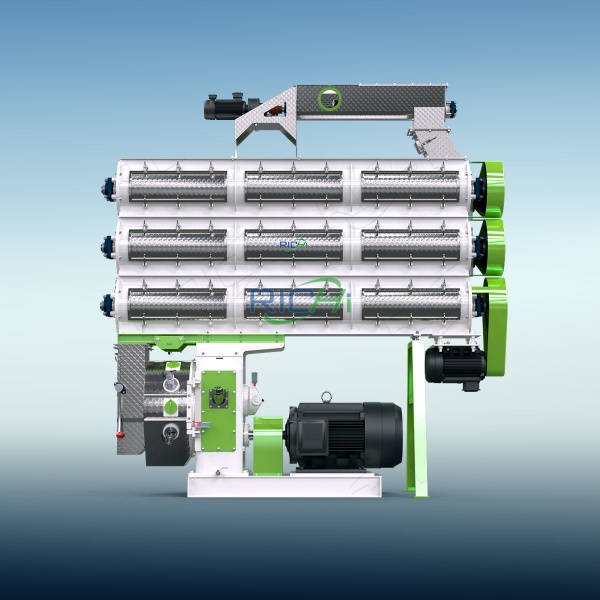

RICHI cattle feed pellet mill for sale is a device specifically designed for the efficient production of high-quality cattle feed pellets. Utilizing advanced technology, it offers stable performance and ease of operation, helping farmers and feed mills improve feed conversion rates and reduce production costs.

Whether for medium-sized or large-scale farms or feed mills of all sizes, this equipment is the ideal choice for achieving efficient, reliable, and high-yield feed production.

What is the cattle feed pellet mill?

A cattle feed pellet mill is a specialized ring die feed pellet machine for processing cattle feed pellets. It can produce pellets with a diameter of 4–10 mm from raw materials such as corn, soybean meal, straw, hay, distillers’ grains, and concentrates. Its core function is to transform loose, powdery or coarse-fiber raw materials into high-density, regularly shaped pellets through an extrusion molding process to meet the nutritional needs of cattle at different stages. This equipment is suitable for a wide range of applications, including large-scale farms, feed processing plants, and family farms.

Whether in feed processing or cattle farming, feed quality is always a key factor. Traditional feed production methods often suffer from low nutrient absorption rates, poor palatability, and susceptibility to mold and spoilage, thus affecting the health and production performance of cattle. Feed pellets processed using a cattle feed pellet mill have higher density, are less prone to breakage or spoilage, and are nutritionally balanced, helping to improve the digestibility and absorption rate and feed conversion efficiency of cattle, thereby promoting healthy growth and improving the production performance of beef and dairy cattle.

Furthermore, the equipment features an energy-saving, low-noise design, stable operation, and effectively reduces energy consumption and improves the working environment. Its high-quality stainless steel ring die and precision gear transmission system ensure the equipment’s durability and smooth operation, while maintaining low maintenance costs. The intelligent control system automatically adjusts production parameters based on raw material characteristics, significantly improving pelleting efficiency and feed quality consistency.

RICHI Machinery is a feed pelleting equipment manufacturer with 30 years of professional experience and enjoys a good reputation in the industry. Our equipment boasts high daily output and stable performance, meeting the long-term production needs of commercial animal feed mill plant and farmers. Today, more and more cattle farms and feed mills are choosing to invest in RICHI cattle feed pellet mills for sale to achieve sustainable, efficient, and scientific feed production. It has become a reliable partner for farmers to improve feeding standards, increase production efficiency, and enhance competitiveness.

video of RICHI cattle feed pellet mill for sale

To provide customers with a more intuitive understanding of the equipment, we have prepared two detailed videos about the RICHI cattle feed pellet mill. The first video showcases the overall appearance and structure of the equipment, clearly demonstrating its robust design, high-quality components, and sophisticated manufacturing process. The second video demonstrates the actual operation of the equipment, showing how it efficiently produces uniform, storable, and nutritionally rich cattle feed pellets. Through these two videos, you can gain a comprehensive understanding of the equipment’s quality, performance, and reliable operation in real-world applications.

Characteristics of RICHI Cattle Feed Pellet Mill For Sale

The RICHI cattle feed pellet mill features a precise and durable structural design, with each component playing a crucial role in ensuring efficient and stable pellet production. From the high-strength body to the stainless steel ring die, from the robust gear transmission system to the advanced conditioning unit, every detail has been rigorously designed and manufactured to ensure a longer service life and higher consistency in feed quality. Understanding the composition of these key components helps users operate the equipment more efficiently, maintain it more conveniently, and achieve optimal production results.

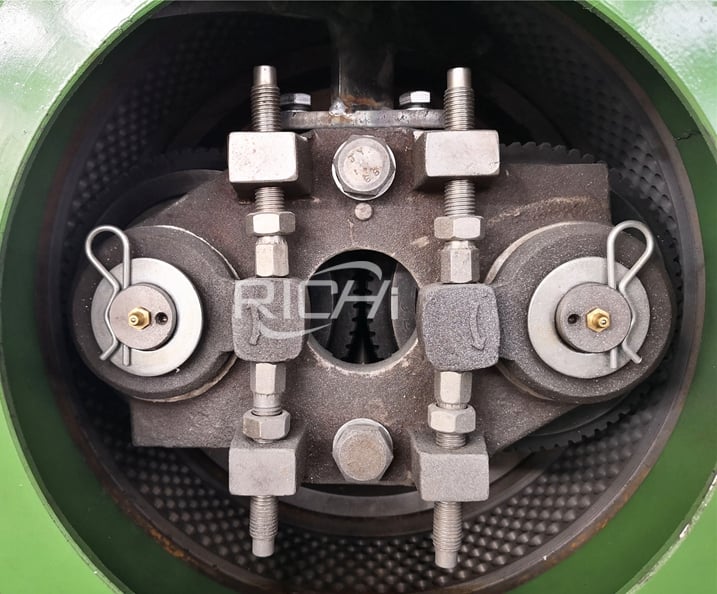

Stainless Steel Pelletizing Chamber

Including press roll assembly, ring die, cutter, scraper, basin, feed chute, manual feed port, by-pass handle.

Gear Box

Gear box includes main shaft, empty shaft, gear shaft, 5 bearings, big gear, safety pin assembly, etc.

Siemens Motor

Main motor is used for coupling and gear reduction. And we all use Siemens motors with high quality.

Conditioner

Conditioner can satisfy ruminant feed pellets. On the cattle feed pellet production line, water vapor from the boiler enters the single-layer conditioner. It has the function of sterilization, curing and increasing yield.

Variable Frequency Feeder

Using variable frequency motor, do not change the voltage, only change the speed, and then change the motor speed, adjust the feed speed. The motor brand is Siemens. The feeder is made of stainless steel

Forced Feeder

This is a feature of cattle feed pellet machine, it is more conducive to granulation of grass-containing feed. It is very necessary for light materials, especially for grass meal and straw meal.

advantages of RICHI Cattle feed pellet mill For Sale

As a manufacturer of feed machinery, we have high quality and reasonably priced cattle feed pellet mill for sale. It can precisely proportion local raw materials according to the nutritional needs of cattle at different growth stages, and turn them into high – quality feed that’s easy to eat and nutritionally balanced. With its highly automated production mode, it reduces manual intervention and greatly improves production efficiency. This helps ranches effectively control cattle feed manufacturing plant cost, and then comprehensively enhances their operational efficiency and market competitiveness.

Diverse raw material compatibility

It can handle various raw materials like grains, soybean meal, straw, and grass powder. It’s adaptable to different feed formulas to meet the nutritional needs of cattle at different growth stages.

Great pellet quality

The pelleted feed it produces has high hardness, a smooth surface, and is fully cooked inside. It can improve the digestion and absorption rate of cattle. It can also kill parasite eggs and pathogenic microorganisms to reduce the risk of diseases.

High efficiency, energy saving and durable

Our cattle feed pellet mill for sale adopts an advanced transmission system and optimized design, with high production efficiency and low energy consumption. Key components like the pressure roller and die are made of high – quality stainless steel, which has stable operation and a long service life.

Convenient for storage and transportation

The pellet feed is small in size and large in density, not easy to disperse. This makes it convenient to store and transport, effectively reducing mildew and nutrient loss during storage.

A win-win in both economic and taste

It can increase feed utilization, reduce waste, and cuts costs. The pellet feed has pleasant baking aroma and good taste which can increase the feeding volume, growth rate and milk production of cattle.

Different Models With RICHI Cattle feed pellet mill for sale

RICHI machinery relying on its own experience, has developed various models of feed pellet mills that can meet your different needs. Whether you are just entering the cattle farming industry or have been engaged in it for many years and wish to replace your old equipment with new ones, RICHI your best choice. Next, we will introduce the specific parameters and model of our cattle feed pellet mill for sale to help you make a faster and more informed purchasing decision.

SZLH250 Small Cattle Feed Pellet Mill

- Main Motor Power (KW): 22

- Capacity: 1-2T/H

- Price: $7,000-10,000

SZLH320 Cattle Pellet Machine

- Main Motor Power (KW): 37

- Capacity: 3-4T/H

- Price: $10,000-20,000

SZLH350 Feed Pellet Mill For Cattle

- Main Motor Power (KW): 55

- Capacity: 5-6T/H

- Price: $25,000-32,000

SZLH420 Cattle Feed Pellet Making Machine

- Main Motor Power (KW): 110

- Capacity: 10T/H

- Price: $32,000-40,000

SZLH508 Cattle Feed Mill

- Main Motor Power (KW): 160

- Capacity: 15T/H

- Price: $40,000-50,000

SZLH558 Cattle Feed Pellet Mill

- Main Motor Power (KW): 185

- Capacity: 20T/H

- Price: $50,000-60,000

SZLH678 Cattle Pellet Mill Machine

- Main Motor Power (KW): 250

- Capacity: 30T/H

- Price: $60,000-70,000

SZLH768 Cattle Feed Pellet Mill

- Main Motor Power (KW): 315

- Capacity: 401T/H

- Price: $70,000-85,000

How to choose A Suitable Cattle feed pellet mill?

Choosing the right cattle pellet machine is of great help in improving feeding efficiency, ensuring feed quality, and reducing production costs. RICHI cattle feed pellet mill for sale has accumulated a lot of practical experience and can meet all the needs of customers.

Cattle Feed Pellet Mill For Sale Global

With over 30 years of experience, we have successfully delivered numerous cattle feed pellet machine projects and customized pellet plant solutions in over 140 countries and regions. We tailor tailored equipment to each client’s specific needs, including production scale, feedstock composition, and desired pellet diameter. We ensure each client receives a system that perfectly matches their production goals, delivering efficiency, cost savings, and long-term value.

Cattle Feed Pellet Mill For Sale Australia

- Country: Australia

- Capacity: 3-5T/H

- Customer Needs: The customer demanded that the pellet machine be simple and easy to operate, with low energy consumption. It should be able to process large amounts of local fibrous raw materials like oat straw and hay. The produced pelleted feed must be suitable for dairy cows, with loose and easily digestible particles that can be stored for a long time and not deteriorate.

- Solution: We chose the SZLH – 350 cattle feed pellet mill, which has a production capacity of 3 – 5T/H. It has a compact structure and is easy to operate and maintain. It produces large diameter pelleted feed of 8 – 10mm. During the pelleting process, we add anti – mold agents and use a low – temperature drying process to ensure the storage stability of the pelleted feed in a humid environment.

Cattle Feed Pellet Mill For Sale Brazil

- Country: Brazil

- Capacity: 5-7T/H

- Customer Needs: They required a high production capacity to meet their long-term feed processing needs. In addition, the pellets had to be easy to store, highly digestible for the animals, and compatible with a wide range of raw materials, especially silage and various types of straw.

- Solution: We chose the SZLH – 350 cattle feed pellet mill. It has a production capacity of 5 – 7T/H and can produce 6 – 8mm pelleted feed. This meets the fiber intake needs of dairy cows. At the same time, it retains vitamins and other nutrients through an intelligent tempering system.

Cattle Feed Pellet Mill For Sale USA

- Country: USA

- Capacity: 10-12T/H

- Customer Needs: It should be suitable for feeding large herds of beef cattle. It needs to produce high – energy and high – protein pelleted feed. The pellet machine is required to have ultra – high stability and continuous operation capability, and can process raw materials such as corn, soybean meal, alfalfa, etc. The pellets must ensure moderate granular hardness and high forming rate, and is suitable for long-distance transportation and storage.

- Solution: We selected the SZLH – 558 large – scale cattle feed pellet mill, which can reach a production capacity of 10 – 12T/H. It produces 4 – 6mm pelleted feed. We ensure the pellet hardness meets the transportation requirements.

Why Choose Our Cattle Feed Pellet Mill

Choosing a reliable cattle feed pellet mill is key to achieving efficient, stable, and profitable pellet production. As a leading pellet equipment product manufacturer, RICHI’s cattle feed pellet mills are trusted by farms and feed processing plants worldwide for their durability, precision design, and excellent adaptability to various feed ingredients. The equipment can easily process a variety of cattle feed ingredients, including corn, soybean meal, hay, straw, and concentrates. Specially designed to meet the nutritional needs of cattle, it ensures stable operation, high pelleting rate, and consistent pellet quality, making it an ideal choice for medium to large-sized farms and large commercial feed mills.

High Quality & International Certification

Each livestock feed pellet mill for sale is manufactured with premium-grade steel and advanced CNC processing technology. RICHI’s strict quality control system ensures that every unit meets international certification standards such as CE, ISO, and SGS.

This guarantees safe operation, high stability, low failure rate, and long service life, making our equipment a dependable choice for farms and feed mills seeking consistent and efficient cattle feed production.

Customized Design for Your Specific Needs

This equipment is specifically designed for cattle feed production. Its feeding, conditioning, pressing, and discharging systems are optimized to stably process powdery and fibrous raw materials, reducing clogging and ensuring smoother and more efficient operation.

RICHI also offers a variety of customized configuration options, including coolers, dust removal systems, and automated packaging systems, helping you create a cattle feed pelleting production line perfectly matched to your production needs, raw material characteristics, and investment budget.

Rich Industry Experience and Trusted Reputation

With over 30 years of experience, RICHI Machinery has successfully delivered pellet production projects in more than 140 countries. Whether it’s a medium-to-large farm or a factory of any size, our engineering team provides complete project planning, installation, commissioning, and after-sales support.

RICHI Machinery turnkey service delivers more than just equipment; it provides customers with a comprehensive, efficient, and profitable pellet production solution.

Why make Cattle feed pellets?

Optimized feeding and digestion

The pelleted feed exudes the aroma of grain through high temperature, which enhances the appetite of cattle; the granulation process has matured the materials, which helps to improve the food digestibility of cattle herd and promotes growth.

Ensure nutritional balance

Various raw materials such as corn and soybean meal can be fully mixed and granulated to avoid nutritional imbalance caused by cattle picky food; at the same time, the particle structure is dense, reducing the loss of vitamins, trace elements, etc. in storage.

Easy for storage and transportation

The pellet feed has low moisture content, good breathability, and a long storage time; its accumulation density is high, saving storage space, and is not easy to scatter during transportation, with small losses, reducing production costs.

FAQ

To help our customers gain a more comprehensive understanding of our cattle feed pellet mill for sale, we have compiled a series of frequently asked and representative questions. Whether you are a first-time investor or an experienced farmer, the following Q&A will provide valuable guidance for choosing the right equipment and optimizing your feed production process.

What raw materials can the cattle feed pellet mill process? Can it process various types of forage simultaneously?

+

The RICHI cattle feed pellet mill for sale can process a wide range of raw materials including corn, soybean meal, wheat bran, grass, alfalfa, straw, rice husk powder, cottonseed hulls, concentrate feed, and other common cattle feed ingredients. It can process multiple types of forage at the same time—as long as the raw materials are properly crushed and mixed before entering the pellet mill. By using a grinder and mixer, different forages such as alfalfa, ryegrass, Sudan grass, and oat grass can be blended evenly and pelletized together without affecting pellet quality. RICHI’s conditioning and compression system is designed to handle high-fiber materials, ensuring smooth operation and stable pellet formation even when mixed forages are used.

I’m planning to invest in a large farm. Do I need the entire production line or just the pellet mill?

+

Whether you choose a complete animal feed pellet production line or just a pellet mill depends primarily on the size of your ranch, your daily feed consumption, and your requirements for the consistency and quality of the final pellets.

If your ranch requires a large volume of feed daily, a complete production line is generally a more efficient choice. A complete line includes crusher, mixer, animal feed pellet mill, pellet cooler machine, screening, and animal feed bagging machine, ensuring consistent pellet quality, nutritional balance, continuous production, and labor savings.

However, if you already have crushing and mixing equipment, or if your raw materials are primarily pre-treated materials (such as commercial concentrates, chopped hay, mature formulations, etc.), then purchasing just the pellet mill itself may suffice.

If you are still unsure which option is right for your ranch, RICHI can recommend the most cost-effective configuration based on your raw material types, power availability, ranch size, and daily production targets.

Hello, I’m from Brazil. I would like to know about the cattle feed pellet mills for sale. Our raw materials are corn, soybean meal, and straw. I would like to ask what the price of a pellet mill is? What are the processes needed to process into feed pellets?

+

I’m glad to receive your inquiries. The price needs to be determined according to the model you need. In addition, if there is a customization requirement, the price will also vary according to the customization situation. As a stand-alone device, the cattle feed pellet machine price ranges from about $7,000 to $85,000.

The production process of cattle feed pellets can be roughly divided into steps such as crushing, mixing ingredients, pelleting, cooling and packaging. We can also provide high-nutrition ratio solutions to help you produce better feed pellets.

We also have a 1-40 tons/hour cattle feed pellet production line, which can help you with specific planning and construction of relevant factory buildings and construction section designs. Please inform us of your production capacity and more detailed requirements about pelletizers, and we will provide you with more detailed solutions and specific prices.

My raw materials include wet grass and high-fiber straw. Will the machine get clogged?

+

RICHI’s cattle feed pellet mill for sale is specifically engineered to handle tough, high-fiber raw materials such as straw, hay, and forage grass. However, wet materials do increase the risk of clogging, not because of the machine design, but due to excessive moisture that prevents proper compression inside the die. For best results, it is recommended to keep the raw material moisture at 12%–18%. If your materials contain wet grass, simple sun-drying or using drying equipment before pelletizing will significantly reduce blockage and improve pellet hardness and durability.

In addition, the machine is equipped with large-diameter feeding ports, variable-speed feeders, and anti-bridging structures, which help ensure smooth feeding and stable output even with coarse, fibrous materials. If your farm processes a high proportion of wet forage, RICHI can also provide customized conditioners, forced feeders, and moisture-control solutions to further minimize clogging.

Can a single cattle feed pellet mill produce pellets of different sizes for calves and adult cattle? Can it be used to produce feed for other animals?

+

Yes. RICHI cattle feed pellet mill for sale can produce different pellet sizes simply by replacing the ring die. For calves, smaller pellets such as 4–6 mm are recommended for easy digestion, while adult cattle typically use 6–10 mm pellets. The die-changing process is quick, allowing one machine to support multiple feeding stages.

The machine can also be used to produce feed for other animals. By adjusting the formula and choosing the right die size, it can process feed for sheep, goats, horses, camels, deer, pigs, rabbits, and other livestock. This makes it suitable for mixed-breeding farms and feed processing facilities that require multi-purpose production.