2-3 T/H Full Automatic Biomass Wood Pellet Line in Canada

The 2-3 T/H full automatic biomass wood pellet line in Canada processes wood chips and sawdust into clean fuel.

Project Overview

RICHI designed a 2–3 T/H full automatic biomass wood pellet line in Canada for processing high-moisture wood chips and sawdust. The line helps the client turn waste into export-grade fuel. We set a smart solution for modernizing wood processing and boosting profits.

2 – 3

Production (ton/hour)

6 – 12

Pellet size (mm)

- Project Country: Canada

- Project Name: Full Automatic Biomass Wood Pellet Line

- Production Capacity: 2–3 tons per hour

- Client Raw Materials: 50% moisture wood chips and 50% moisture sawdust

- Final Product & Size: Biomass pellets, 6.0–12.0 mm in diameter

- Main Equipment Included: Wood crusher, shifter, dryer, storage bin, wood pellet press machine, cooler, shifter and automatic packing system

- Project Start Date: August 1, 2022

- Installation Period: 60 days

- Number of Engineers Dispatched for Installation: 1 engineer

- Plant Area Used by Our Equipment: 26 × 20 × 12 meters

- Power Consumption: 200 kW/hour

- Labor Required for Operation: 6 workers

Client Background & Challenges of building 2-3 T/H Full Automatic Biomass Wood Pellet Line in Canada

The client is a medium-sized sawmill and wood processing company located in Canada. For many years, it has been mainly engaged in log sawing and board processing. It has long produced a large number of by-products – sawdust and wood chips with high moisture content (about 50%). In the past, these wastes were often regarded as ancillary resources, some of which were sold at low prices and some were abandoned. However, with the growing demand for clean energy in the international market, especially the surge in imports of biomass pellet fuels in European and Asian countries, the client realized that this was a huge export opportunity with great potential.

Against the background of the vigorous promotion of renewable energy substitution in countries such as the United Kingdom, Japan, and Italy, Canadian wood pellets are widely popular because of their clean raw materials and standardized processing. In order to seize export opportunities, the client decided to transform and enter the biomass pellet market to achieve raw material reuse and business upgrades.

However, the client faced many technical challenges: its existing plant was originally a traditional sawmill with a special structure and limited area. To install a fully automatic pellet production line with a capacity of 2-3 tons per hour in it, a comprehensive customized design is required. At the same time, raw materials with high moisture content also place higher requirements on drying and stable output.

The client required a wood pellet manufacturing plant solution that was compact, efficient and in compliance with export standards, ensuring that the wood pellets produced met international quality requirements while operating efficiently in a limited space.

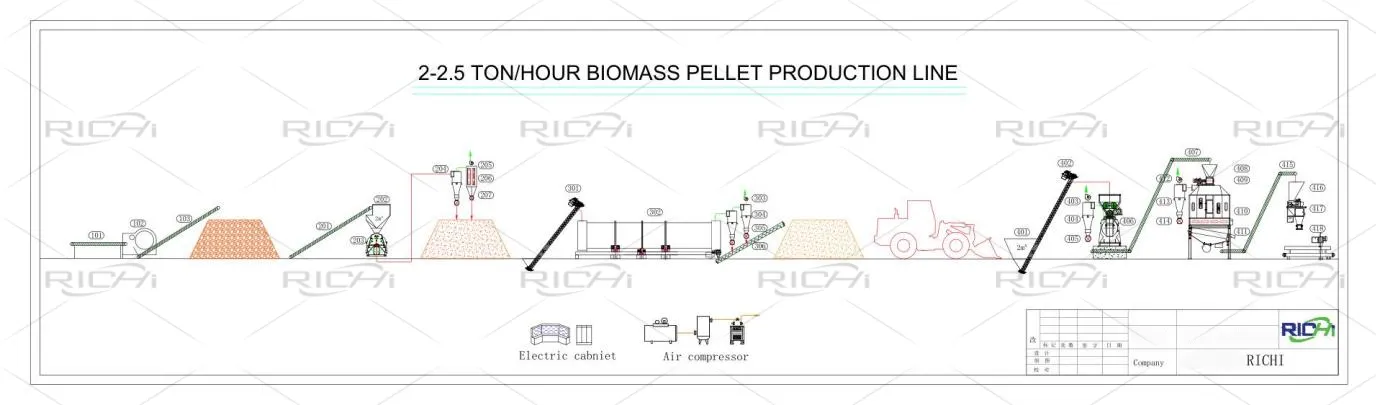

Tailored Solution & Equipment Layout of the 2-3 T/H Full Automatic Biomass Wood Pellet Line in Canada

We provide a full set of customized 2-3 T/H Full automatic biomass wood pellet line in Canada for our client’s special structure and limited space in the sawmill workshop. Engineers carefully design the layout of the production line to fit within a space of 26x20x12 meters, ensuring a smooth process without compromising production capacity.

The line is equipped with a wood grinder, dryer, pelletizer, cooler and automatic packaging system. The layout of the entire production line is compact, taking into account both space and energy efficiency. Especially in the drying section, it is optimized for raw materials with 50% moisture content. This ensures the drying and stabilization of the granules.

Efficient Installation with Full After-Sales Support

In order to ensure the smooth commissioning and long-term stable operation of the biomass wood pellet production line in Canada, we provide all-round technical support after delivery. Not only did we send a senior engineer to guide the installation on site, but we also provided remote guidance online throughout the process. Combined with a detailed layout plan and centralized control system, the installation could be completed by only six local workers.

After installation and commissioning, the engineer trained the operators on site. The training covers equipment operation, routine maintenance and safety practices.

We provide customized maintenance plan and 1-year free warranty and lifetime technical support except for wearing parts. In addition, the after-sales team makes regular visits. This ensures the normal operation of the production line after commissioning. We also provide ongoing maintenance advice and technical services.

Overall, RICHI team provides one-stop service to our clients from installation, operation to after-sales.

Customer Feedback & Project Outcomes of 2-3 T/H full automatic biomass wood pellet line in Canada

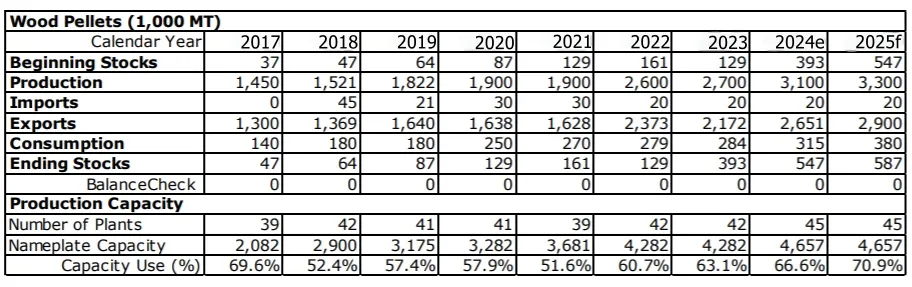

Since its commissioning, 2-3 T/H full automatic biomass wood pellet line in Canada has produced a steady output of 2.5 tons per hour. It is capable of converting 10 tons per day of high water content wood waste into clean biomass pellets. The client is now exporting an average of about 200 tons of pellets per month to countries such as the United Kingdom and Italy, generating revenues in excess of C$40,000 per month.

In addition to the good revenues, the production line’s energy consumption and costs are kept within reasonable limits. The fully automated production line greatly reduces labor costs. Only 6 workers are needed to operate the whole line successfully. It is worth mentioning that the power consumption is about 200 kWh. With very stable operation and minimal maintenance downtime, RICHI has designed a line that reduces operating costs in all aspects and realizes efficient and energy-saving production.

Six months after the project was successfully put into operation, we also received the following feedback from the client:

“Your team have helped us to turn our waste into profit. The system is running stably and the first batch of export passed the inspection. We are planning to add a new high-grade pellet production line.”

We are looking forward to the next stage of cooperation with our client.

Export Outlook: Opportunities for Canada’s Wood Pellet Industry

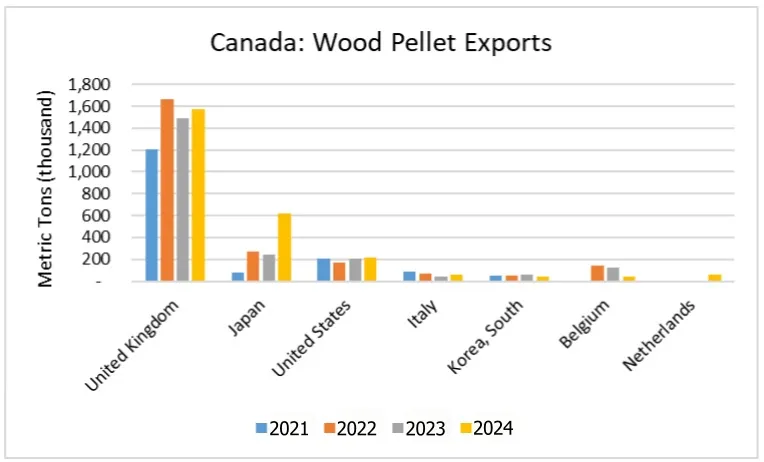

*Canada Wood Pellet Exports by Country Share

According to data from Natural Resources Canada (NRC), Canada’s wood pellet exports have continued to grow steadily. Charts indicate a significant increase in export volumes since 2016, reflecting the strong global demand for clean and renewable fuels. The main export destinations are energy-transition countries such as the United Kingdom, Japan, and Italy. Both European and Asian markets hold great potential.

Meanwhile, the utilization rate of Canada’s wood by-products—such as sawdust and wood chips—has been increasing year by year. The industry is shifting from traditional log exports to higher-value-added pellet fuel production. Biomass wood pellet line in Canada are becoming a key development direction for export-oriented wood processing enterprises.

At present, the Canadian wood processing industry is undergoing a structural adjustment from traditional log exports to deep-processed and high-value-added products exports. Government policy encourages the development of biomass energy. At the same time, markets trends are pushing companies toward “green exports”. Under this background, biomass pellet projects have become an ideal entry point for client to transform their business.

*Canada Wood Pellet Market Statistics (2017–2025)

Ready to Turn Your Wood Waste into Export Value?

Are you looking to upgrade your biomass pellet production line and seize the growing export opportunities in the global clean energy market? Do you want to set up the biomass wood pellet line in Canada? With rising demand across Europe and Asia, converting sawdust and wood chips into biomass pellets has become a clear market opportunity. Do you want to ride the wave of international trade and step into the booming blue ocean of clean energy

No need to wait and hesitate, just contact us for a turn key solution. RICHI has successfully helped many Canadian clients turn low-value by-products into high-profit export products. Whether you’re facing space constraints, raw material challenges, or strict export standards, we have the proven technology and experience to help you succeed. You can also check more cases on our youtube channel.

Partner with us to build your own biomass pellet export project.