1-1.5 T/H Biomass Pellet Line in Indonesia

The 1-1.5 T/H biomass pellet line in Indonesia processes local biomass materials into clean fuel.

Project Overview

RICHI Manufacture has started to build a 1-1.5 T/H biomass pellet line in Indonesia for a client from Indonesia in December, 2018. After the project went into production, the demand for wood pellet fuel in Southeast Asia also increased. The customer is very satisfied with the complete wood pellet plant and has made a profit.

1-1.5

Production (ton/hour)

6-12

Particle size (mm)

- Country: Indonesia

- Raw Material: wood plate waste

- Finished Product Size: 6.0-12.0mm biomass pellets

- Main Equipment: Hammer mill, storage silo, biomass pellet making machine, cooler, shifter, and simple ton bag packing system

- Installation Time: 30 days

- Project Start Date: December 30, 2018

- Engineers On-site: 2 engineers

- Working Area Required: 12 meters (L) x 8 meters (W) x 8 meters (H)

- Power Consumption: 200 kW/hour

- Labor Requirement: 3 workers

- Warranty: 2 years for all non-wearing parts, lifetime free technical support

Client Background & Challenges of building the biomass pellet line in Indonesia

The client runs a small to medium wood panel manufacturing plant in Indonesia. The enterprise is mainly engaged in the production and processing of wood-based products. During the daily processing work, the client can make massive light and long left over bits and pieces.

These kind of marginal wastes are bulky and of low density so that they are not to store. The wastes not only can not be burned directly but also can only make low commercial value. During daily production, such marginal wastes place significant pressure on environmental protection efforts and lead to substantial resource wastage.

To deal with it, the client hope to build a stable and efficient biomass pellet line in Indonesia. By doing so to turn the waste into high quality biomass pellet that could be sold or used as utilizable fuel resources. So that fulfill the purpose of efficient resource utilization and increase economic returns.

However, duel to the specificities of the raw material (light in weight and long length), ordinary equipment is difficult to effectively pulverize them. It will further influence the production and duality. The client urge to find a customized solution that could handle this unique material.

Tailored Solution by RICHI

After understanding and analyzing the client’s requirements, RICHI customized a 1-1.5 T/H biomass pellet line in Indonesia for them. This solve the core problem that normal equipment can hardly pulverize long and thin raw materials.

Among them, core section is that RICHI selected a special-type hammer mill optimized for handling long and fibrous materials. Optimized for deal with fibrous lightweight materials, this machine ensures a smooth feeding and fast pellet. This perfectly solute the problems such as the material can be easily clog in the machine.

The whole production line also equipped with storage silo, biomass pellet making machine, cooler, shifter and simple ton bag packing system. The layout of all machines is very compact. With a footprint of only 12x8x8 meters, it perfectly adapted the client’s small factory space.

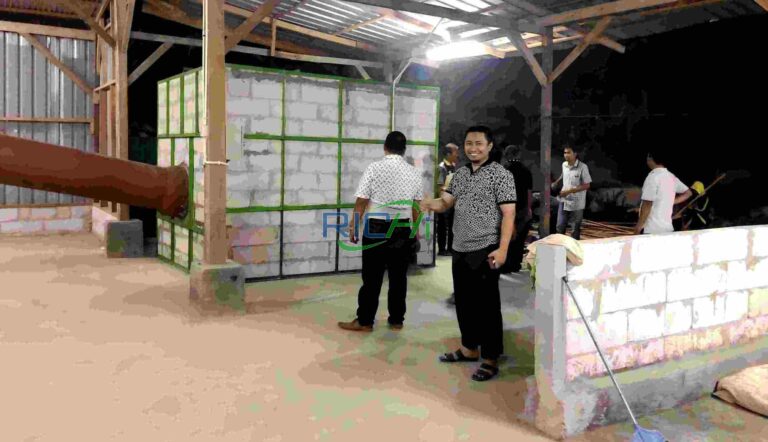

Implementation & Commissioning

The energy consumption of the 1-1.5 T/H biomass pellet line in Indonesia is about 200kWh and only need 3 operators. Meanwhile, RICHI provide all installation and equipment layout drawings(include the layout of wood pellet line in workshop, the installation drawings of equipment and steel support) in advance. Thus the client’s team was able to prepare the site efficiently before the engineers arrived.

With two professional engineers arrive at the construction sites in Indonesia for technical guidance, the whole installation process last only 30 days. The whole guidance covers mechanical assembly, electrical wiring, system calibration and trial production.

During the whole process, RICHI also provide real-time remote support. This helps the clients to get the first solution in case of some unexpected problems.

For example, when installing the auto packing equipment, workers found that the switch could be turned on but the equipment did not operate properly. After our remote guidance, we found that workers had mistakenly installed the upper and lower interfaces the other way around. In the end, we completed the project on schedule and ensured smooth operation.

Results & client Feedback of the 1-1.5 T/H Biomass Pellet Line in Indonesia

After the project was put into operation, the set of biomass pellet production line quickly entered into stable operation. The overall equipment runs smoothly with low failure rate. The quality of the finished pellets is stable — Diameter is at about 6-12mm, the appearance is uniform and the water content is low. This fully meets the client’s standards for self-consumption and export.

It is worth mention that the customized pelleting system performances perfectly when processing the light and long wood plate waste, efficiently solving their long-standing raw material handling problem.

Here’s what the client shared with us during the follow-up visit after the biomass pellet line in Indonesia was put into stable operation:

“RICHI’s team was professional and responsive from the beginning to the end. The solution really fit our material. Now we finally turn waste into value.”

After one year stable operation, we got the feedback from our client again:

“It’s been over a year since we started running the biomass pellet line in Indonesia and it’s still working smoothly. RICHI’s support team remains responsive whenever we have questions. We’re already considering a second line. Hope to cooperate with your team in the next time.”

Why the Client Chose RICHI

Before placing the order, the client compared several pellet equipment suppliers in China. Most of them were unable to provide an exclusive solution for its lightweight and slender wood plate waste.

In contrast, RICHI not only customized the entire biomass pellet line in Indonesia design according to the characteristics of the raw material but also provide a detailed plant layout and implementation schedule in advance. So that the client has a clear expectation of the entire project process. At the same time, the client was impressed by RICHI’s technical responsiveness and professional attitude.

In addition, RICHI has wealth of overseas project experience in Southeast Asia and other regions. The client of the 1-1.5 T/H biomass pellet line in Indonesia has expressed confidence in the quality of its equipment and after-sales service as well.

The more competitive price under the same quality premise was also an important factor that prompted the client to choose RICHI in the end. After comprehensive consideration, the client firmly chose RICHI as a partner help to design and build the biomass pellet line. You can check more cases in our youtube channel.

Want to Replicate This Success?

Dealing with these problems?

Are you dealing with lightweight wood plate materials that is difficult to shred and mold? Do you want a customized production line fit all of your produce requirement? Do you want to se up a biomass pellet line in Indonesia or other countries?

Want to boost your business?

Just like our clients in Indonesia, perhaps you are looking for a reliable and efficient way to turn waste into profit. RICHI provides customized biomass pellet solutions specifically designed to meet your needs—whether you have limited plant space or challenging raw materials, we deliver the right solution for you.

Contact us

Contact us now to build your own highly efficient and low-consumption pellet production line.