build your ideal animal feed processing plant

Animal Feed

Processing Plant

Customized designs to optimize feed quality, output and operational efficiency.

Animal Feed Processing Plant

— Richi Machinery —

brief introduction

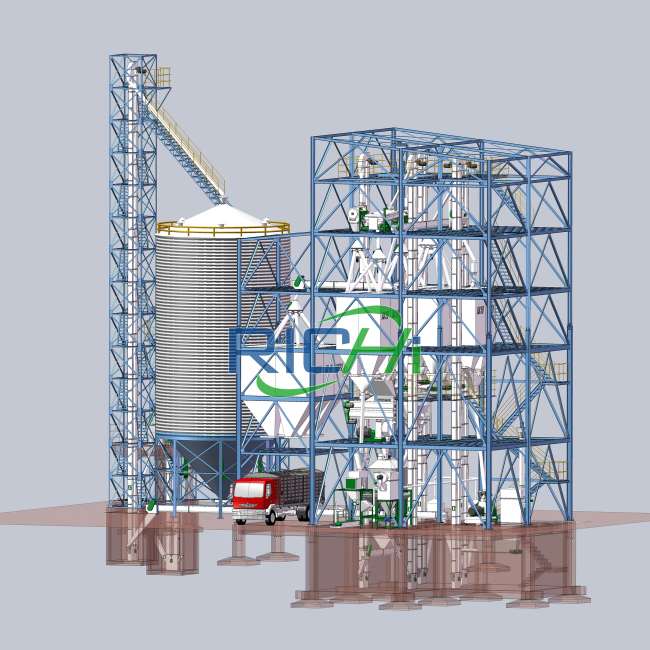

Animal feed processing plant is a complete process system designed to turn raw materials(such as corn, cereal, Nutshells and straw etc.) into uniform, nutritional animal feed. The common process include grinding, mixing, pelleting, cooling, crushing and packing. The output line can play a role in improve the working efficiency, control the quality and save the labor cost.

For the development of the present breeding industry, more and more companies need excellent animal feed. Single products can not reach the standard for industry owners who are looking for the good quality of the animal feed. Beside, following the world development, food requirement is keep rising. We need large amount of animal products, such as meat, eggs, milk and so on.

Under this background, the animal feed production plant is suitable for many companies. It is a kind of complete product mode no only boost the product efficiency but also reduce time and transport cost. Distinguished from the traditional feed pellet working mode (using the household single feed pellet machines), this kind of animal feed processing plant features higher automation and larger scale production.

Usage

It is widely used in feed mills, farms, and animal husbandry operations.

Raw materials

Corn, soybean meal, wheat bran, rice bran, fish meal, bone meal, alfalfa, grass powder, vegetable oil, vitamins, minerals, etc.

Production

1-80 (tons/hour)

particle Size

1-12 (mm)

Types of animal feed processing plant

To reach different requirement of different usages, the production line can be divided into different parts.

1. Animal type

Categorized by the type of animal, our generating lines can be classified into poultry feed production line, livestock feed production line and aquatic feed production line. No matter what kind of animal feed you want to product. We can always satisfied you.

2. Production scales

Classified by the production scales, we have small-scale feed line(1-2 tons per hour), medium-scale feed line(3-10 tons per hour) and large-scale feed line(suitable for industrial feed factories, output more than 10 tons per hour, equipped we automatic system and artificial control).

3. automation degree

According to the degree of automation, we offer semi-automatic feed line (low cost) and fully automatic feed line (high efficiency).

RICHI MACHINERY

Technical features & highlights of our animal feed processing plant

RICHI has a professional research & design team. Via 15 years constant effort, We have developed more than twenty patented technologies. Some highlights are as follow:

Wide material compatibility

Capable of different raw materials like corns, soybean meals, rice husks and so on. Our machine supports diverse feed.

Durable construction

Our machine are made of carbon steel and stainless steel which can provide a sterile working environment, ensure food grade safety and offer a long service use.

Modular design for flexible expansion

The whole production line adopts modular structure. Customers can flexibly upgrade or expand a part according to actual needs without replacing the whole system.

Integrated automation system

The whole animal feed processing plant integrates complete automatic process from grinding, mixing, pelleting to cooling, crushing and packing. As a result, it significantly reduces labor costs while boost production efficiency.

Environmental Design

The machine integrated noise reduction equipment and dust collect installations helps to create a eco-friendly working environment.

Smart control Technology

Equipped with PLC control system, operators can flexibly adjust temperatures, pellet size and cooling time. In this way, it will consistently ensure the pellet quality while minimizing industry waste.

RICHI MACHINERY

How this system benefits your business?

Though the technical features highlight the structural design and operating steps, the real benefits under these high-tech of our animal feed production plant is also deserve to known.

What advantages these features actually brings us and what make RICHI truly stand out from other industry companies?

Let’s take a closer look of the real benefits these technologies can bring us:

high production efficiency

Compared with the traditional industrial production model, modern animal food processing plant can significantly improve the efficiency of production. This makes mass production of animal feed possible.

Fully automated production tools reduce the amount of manpower required, and automated production lines allow many machines to be in production at the same time. Thus the production line can significantly increasing production in the same time. At the same time, this animal feed processing plant method is the right choice for feed mills that need to scale operations.

constant product quality

Another core advantage of the animal feed making line is the ability to consistently and steadily deliver high quality feed products. The entire production process is carried out under strict control.

High-tech products ensure optimum process results at every stage of the production process. In the mixing process, for example a homogeneous mixing system ensures that each pellet is of the same size and that the required nutrients are precisely proportioned.

low production cost

It is able to utilize a wide range of locally available and inexpensive raw materials. Such as corn, soya bean meal and rice husk. This reduces the cost of purchasing raw materials. Production waste can be reused, further reducing material waste and optimizing resources.

Energy efficient equipment reduces power consumption. In the long run, this can bring considerable savings to the animal feed processing plant.

Key equipment for starting an animal feed processing plant

— RICHI Machinery —

To build a high quality and high efficiency animal food processing plant, can’t do without a series of key equipment.

Each machine plays an indispensable role in the process of making raw materials into finished pellets.

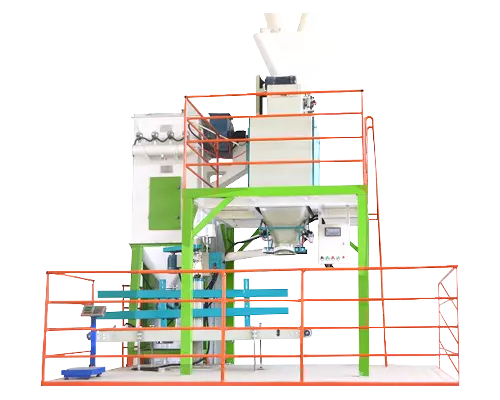

Cleaning/Crushing System

Drying/Mixing

Pelletizing System

Cooling System

Classifying System

Packaging System

Working process design of animal feed pellet production plant

Animal feed processing plant is a complete process system designed to turn raw materials into uniform, nutritional animal feed. The common process include cleaning, grinding, mixing, pelleting, cooling, crushing and packing.

Here is an example of the making line process:

1. Raw Material Cleaning Process

The main task of this process is to clean out the impurities and iron-containing materials from the raw materials. So that the clean material can enter the crushing system. The significance of this process are: First, to ensure product quality. Second, to ensure the pulvetizer be able to work normally.

2. Raw Material Crushing Process

After the raw materials are cleaned, they are gradually transferred to the pre-grinding bin. From there, the materials enter the grinding machine for processing. The main purpose of this stage is to crush the raw materials to a specified fineness according to the formula requirements, and then seamlessly convey them to the next stage of the production line.

3. Feed Material Mixing Process

Under the precise control of the PLC system, raw materials are accurately weighed according to the specific feed formulation. Following this, the system complete discharging, weighing and mixing within the shortest possible time.

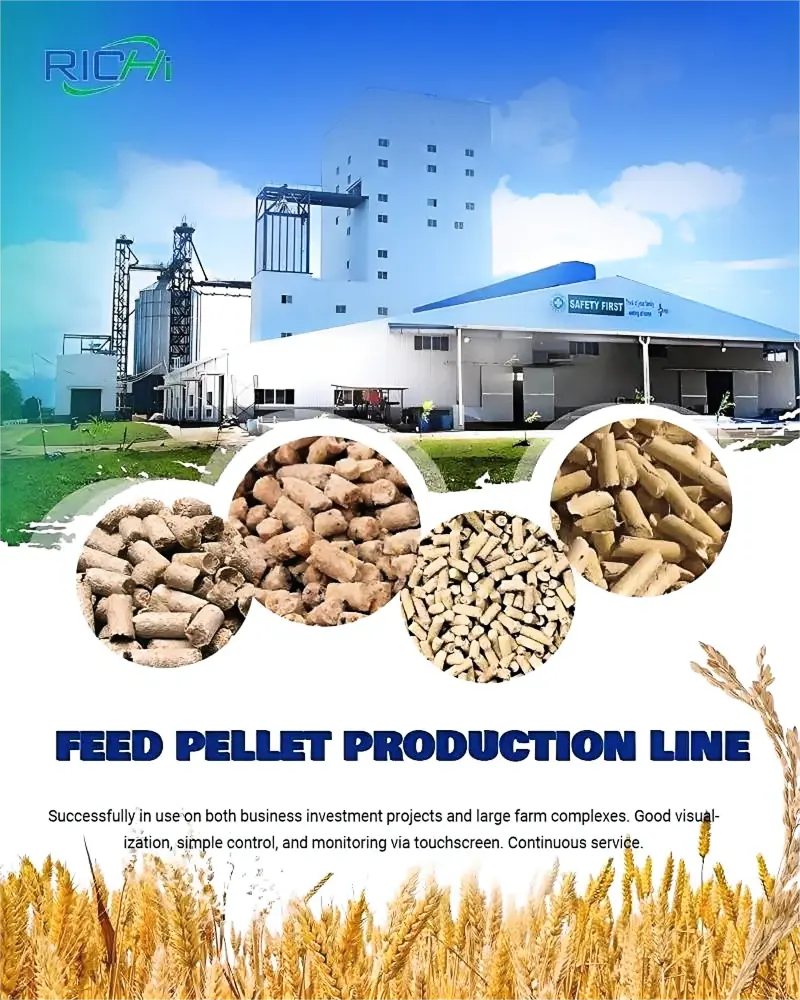

4. Feed Pelletizing Process

This step is to make the ground powder materials into pellets. The pelletized feed offers complete nutrition and improves feed digestbiliy for animals. In addition, it is easier to store and transport. Through thermal processing, harmful bacteria can be eliminated. Moreover, aquatic feed pellets remain stable in water and are less likely to cause water pollution.

5. Feed Pellet Cooling & Pellet Crumbling Process

After the pelletizing step of the animal feed processing plant, the pellets have a temperature of around 80 ℃ and a moisture content of 15-16%, making them unsuitable for packaging. Therefore, they are evenly fed into the cooling bin, where cool air flows through the gaps between pellets, allowing efficient heat exchange.

After cooling, the pellets are discharged layer by layer. Subsequently, pellets requiring size reduction are sent to the crumbler, where they are compressed into the desired size.

6. Feed Pellet Classifying & Packing Process

Using a rotary grading screen to separate out the powder feed. Then, the packaging scale system is activated to weigh, fill, and seal the pellet feed.

RICHI MACHINERY

Infrastructure & Investment Parameters

Based on different technological requirements, various types of animal feed machinery are combined to meet customers’ different animal feed processing plant requirements.

The main data is as follow:

| Scale | Total Power | Site Requirements | Installation Cycle | Animal Feed Mill Cost (USD) |

| 1-2T/H | 47-75KW | 300-500m² | 7-15 Days | 10000-50000 |

| 3-4T/H | 53-165KW | 300-700m² | 15-20 Days | 5,0000-12,0000 |

| 5-7T/H | 68-259KW | 400-800m² | 20-40Days | 7,0000-25,0000 |

| 8-10T/H | 125-410KW | 800-2000m² | 45-60 Days | 150,000-300,000 |

| 12-20T/H | 358-620KW | 1500-3000m² | 60-90 Days | 250,000-580,000 |

| 25-40T/H | 545-870KW | 2000-4000m² | 90-120Days | 45,0000-850,000 |

| 50-60T/H | 710-1120KW | 3000-5000m² | 100-140 Days | 900,000-1,400,000 |

| 60-80T/H | 815-1370KW | 5000-8000m² | 130-160 Days | 1,450,000-1,800,000 |

| 80-100T/H | 1230-1700KW | 8000-20000m² | 160 -190Days | 2,000,000-2,800,000 |

If you need help design your own animal feed production plant, please contact us and tell us your daily output needs, we’ll recommend the best type match to you.

RICHI MACHINERY

Customer stories & project outcomes

01

10T/H animal feed processing plant in Nigeria

In order to meet the large poultry feed requirement, one large agriculture company form Nigeria cooperate with RICHI to set a 10T/H automatic poultry feed pellet plant.

The customer have a need of processing multiple raw materials like corn, wheat bran and so on. RICHI satisfied them with our profession technology and considerate service.

The production line include crushing, mixing, pelleting and packing. Based on customer’s actual space, RICHI customized the layout and offer the staff training, 7×24 hours on-line technical support.

02

20 T/H complete animal feed production project in Brazil

To enhance the feed quality and realize the livestock industry modernization, one large agriculture group company contact us for design a 20T/H automatic animal feed making line.

This project was aimed at producing compound feed, in support of the national food security plan. To meet these requirements, RICHI adopted a modular design approach, combining a steel-structured workshop with a flexible multi-layout configuration.

The production line also equipped with PLC auto-control system, making high efficiency and low labor cost possible.

03

2T/H cattle feed processing plant in Uzbekistan

RICHI go into the partnership with this medium company twice. Despite of the challenge of the cold weather and the complex logistic, the tailored professional animal feed processing plant team still finished the whole install and commission work within six months.

Now the company has been running smoothly over two years. Our productions and service has won a prize among the local people.

RICHI MACHINERY

How to design & build

an animal feed production plant?

Building and setting up a complete feed processing plant requires a deep understanding of both the characteristics of the raw materials and the nutritional needs of the target animal species.

Let along the conditions of local infrastructure. RICHI insist on offering the customization service. Helping the business to realize the maximum value.

Key steps include:

01

1. Requirement analysis

Everything starts with clarity. Firstly, figure out what type of feed are you producing: poultry, cattle, pig or fish feed? Do you need powder feed, pellet feed, or crumbled feed? You want a high efficiency fully automatic control system or prefer a low cost semi-automatic one?

Knowing your target product helps define the equipment layout, raw material needs and output scale. It also affects decisions on automation levels and budget planning of set the animal feed processing plant.

RICHI

02

2. Equipment manufacturing

Not all equipment fits all production plans. The selection depends on your required capacity (tons per hour), power source (electricity, diesel, etc.), factory size, and whether you’re going for manual or fully automated control.

Each piece from hammer mill to packing machine has to match the overall line. Once you choose the suitable equipment, RICHI will manufacturing the core equipment all by ourselves. Extremely rigorous tests are performed throughout the whole manufacturing process.

RICHI

03

4. installation & commission

Once the equipment arrives, installation begins under our professional technical guidance. Each machine is set up, calibrated and tested by our professional staff to ensure it runs properly.

Following installation, the entire line is tested with real materials to make sure the pellets meet the quality standards for size, hardness and moisture.

RICHI

04

4. Customized design

With the product specifications and raw materials confirmed, our engineers begin mapping out the animal food processing plant—much like connecting the dots to form a complete and efficient system. Typically, the process includes grinding, batching, mixing, pelletizing, cooling, crumbling, and packing.

To ensure maximum efficiency, each step is carefully planned to maintain a smooth workflow and eliminate potential production bottlenecks. Regardless of layout complexity or capacity requirements, we are fully equipped to deliver a customized solution that perfectly fits your needs.

RICHI

05

5. After-sale support

Even the most advanced system is only as good as the people running it. That’s why operator training is part of the setup process of the whole animal feed processing plant. In this way your team will know how to run the machines, do basic maintenance and handle unexpected situations.

Our team also offer long-term technical support, spare parts service and even remote monitoring tools.

RICHI

Frequently Asked Questions

Customized solutions can help different customers meet their unique business needs, improve efficiency, and reduce costs.

All of RICHI’s animal feed processing plants are custom designed.

How to choose the appropriate product?

Firstly, consider what kind of animal feed you want to product(poultry feed, cattle feed, fish feed and so on) and to produce it in what form(powder or pellet).

Second, consider how big your factory need to be and what kind of automatic system you want. You can also tell us about your rough budget and we will offer you the best design and equipment under the lowest cost.

After the negotiation, we will give you the best efficiency and return on investment.

Do you have the integration and customization options?

Yes, of course. We have a whole professional team to meet your requirement and serve the best production. Whether you’re building a small-scale unit or a large industrial plant we can all tailor the most suitable equipment size, texture and configuration for you. Just let us know some basic information like your product goals, available space and budget, we will not disappointed you.

Is the animal feed production plant easy to maintain?

Yes, our feed production lines are designed with user-friendly operation and maintenance. Most part of the components are easy to access, clean and replace. We provide a full maintenance manual and video guides, we also manning technical commentator to help your staff handle routine inspections.

Can I expand the production line later?

Yes, absolutely. Our animal feed processing plants are designed with scalability. No matter what size of the business you’re running, whether you’re starting a small-capacity setup or a medium-sized facility, even a large-scale production project, we can make a promise that the layout allow for future expansion.

For other word, if your initial business production is limited, you’re fully prepared for future scale-up. When your business grows, we also hope to start a new chapter of cooperation with you.