Animal Feed Mill Plant

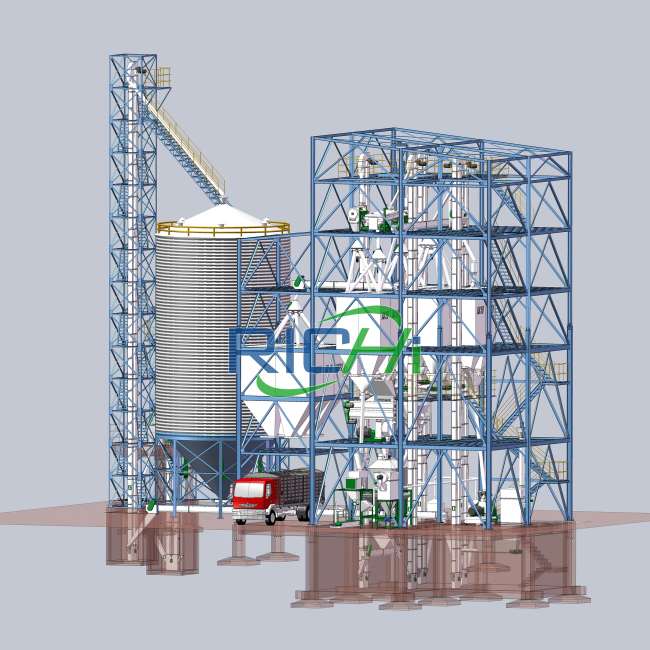

The animal feed mill plant is an advanced manufacturing system specifically designed to process agricultural raw materials such as corn, wheat, soybean meal, and forage into high-quality pellet feed for poultry, livestock, and aquatic animals. This system encompasses multiple stages including cleaning, grinding, mixing, pelletizing, cooling, screening, and packaging, ensuring that the finished feed is nutritionally balanced and easy to store, facilitating the rapid and healthy growth of animals.

brief Introduction of Animal Feed Mill Plant

— Richi Machinery —

brief introduction

The animal feed mill plant system is an advanced manufacturing system. This meets the growth needs of different animals and ensures that the finished feed is nutritionally balanced and easy to store, facilitating the rapid and healthy growth of animals. The feed produced by the system is widely applicable to various livestock and aquaculture sectors such as poultry, livestock, and fishery.

The feed plant mainly consists of a crushing system, a mixing system, a ring die feed pellet machine, a cooling system, and a packaging system. And these equipment work together to ensure the efficient and stable operation of the entire animal feed pellet production line.

Meanwhile, by adjusting the particle diameter, hardness and nutrient content, a single animal feed mill plant can meet the feed production needs of various animals, significantly increasing the return on investment. These include poultry, livestock, aquatic animals, pets.

Whether it’s poultry farms, cattle and sheep ranches, or aquatic farming enterprises, RICHI’s customized feed production lines can significantly enhance production efficiency and meet diverse nutritional requirements. If you have any needs, please feel free to contact us.

Usage

It is widely used in feed mills, farms, and animal husbandry operations.

Raw materials

Corn, bran, soybean meal, fish meal, soybean meal, cottonseed cake, bone meal, wheat bran, etc.

Production

1-100 T/H

pellet Size

1-12 (mm)

Working process design of animal feed plant

The animal feed mill mainly consists of crushing system, mixing system, granulation system, cooling system, and packaging system.

The production process of the animal feed pellet production line is as follows: pre-treatment → crushing → feed mixing → granulation → cooling → packaging

1. Raw Material Pretreatment Process

First of all, before the feed enters the animal feed plant, raw materials such as corn, soybean, wheat bran and straw need to be pre-cleaned to remove stones, metals, weeds and other impurities, so as to improve the cleanliness of raw materials, reduce equipment wear and tear, and ensure the stable operation of subsequent sections and more guaranteed quality of finished products.

2. Raw Material Crushing Process

Then the cleaned raw materials are sent to the crushing system of the animal feed mill plant, where they are processed into target particle sizes using crushers. The grinding of grains, legumes, straw, and other raw materials into appropriate sizes enhances animal digestion efficiency, feed conversion rates, and ensures uniformity and stability during subsequent pellet formation.

Various crusher types are available based on material characteristics and processing requirements. The most commonly used model is the SFSP feed hammer mill.

3. Automatic Batching and Mixing Process

After that, in this stage of the feed pellet plant, the crushed ingredients are thoroughly mixed with additives such as vitamins, minerals, and enzymes to ensure balanced nutrition. The PLC automatic batching system is used to greatly improve the weighing accuracy and formula consistency, which is suitable for high-standard production in medium and large feed plants.

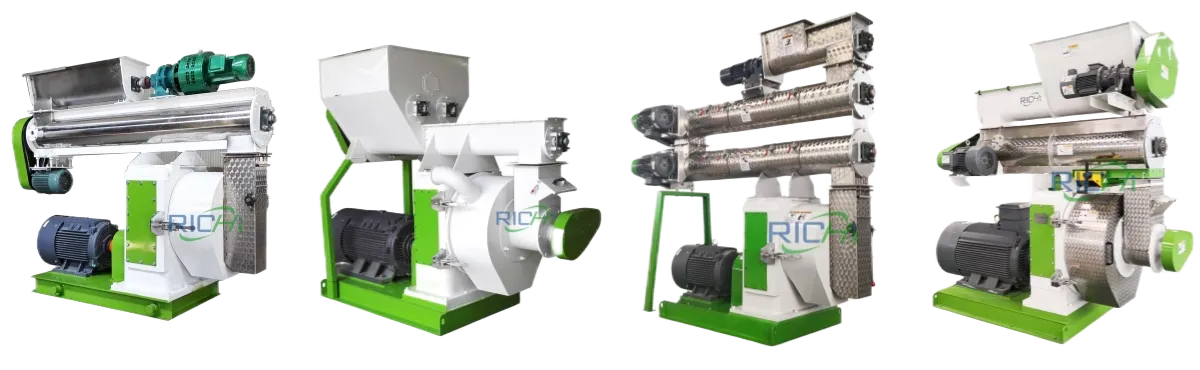

4. Granulation Process

After mixing, the powdered feed is fed into a animal feed pellet mill where it undergoes conditioning, maturation, and sterilization. The material is then extruded through an annular die to form uniform pellets. Depending on different animals’ feeding habits and digestive characteristics, various die configurations with varying pore sizes and compression ratios can be selected to produce pellets of specific hardness and length.

5. Feed Pellet Cooling Process

Newly pressed pellets are usually high in temperature and humidity. If not cooled in time, they are prone to deformation, mildew or nutrient loss during storage. Therefore, pellet cooler machine is needed to cool the feed pellets produced by animal feed mill plant to improve their durability and appearance.

6. Screening and Packing Process

Finally, even after molding, there may still be some fragments and powder. Before storage or delivery from animal feed mill, the system uses vibrating screens to remove powder or oversized particles. After screening and cooling, the qualified particles are automatically packed by animal feed bagging machine.

RICHI MACHINERY

equipment needed in animal feed mill plant

After completing the introduction of the production process, we turn our attention to the technical support behind it – the key equipment required for each step. It is the efficient collaboration of these devices that forms a smoothly operating and stable feed production line. Then, we will briefly introduce the main equipment commonly used in animal feed factories for you, helping you quickly understand the configuration required for the entire line and providing a reference for selection and investment decisions.

At the same time, in order to ensure the overall efficient and stable operation of the animal feed processing plant, various auxiliary equipment is also provided.

The feed pellet machine is the core component of any animal feed mill plant. So it directly determines the quality, density, and digestibility of the final feed pellets. RICHI Machinery offers a full range of high-performance feed pellet machines designed to meet the needs of different capacities, feed types, and processing requirements.

RICHI MACHINERY

Global Case related to animal feed mill plant

01

- Country: Rwanda

- Project name:1-2 T/H animal feed processing plant in Rwanda

- Main Raw materials: Corn and soybean meal

- Total Power: 50KW

- Feed Pellet Size: 2mm, 4mm chicken feed pellet

- Plant size of project factory:& 10m*5m*12m (L*W*H)

- The operate worker in this line: 3-5 person

02

- Country: Uzbekistan

- Project name:10T/H Animal feed processing plant for Uzbekistan

- Main raw materials: corn, wheat, sunflower seed, oil, premix, etc.

- Total power of project: 520kw

- Feeds that customer needs: 0.5-12mm chicken feed pellet, chicken mash feed

- Plant size of project factory: 35m*20m*25m (L*W *H)

- Capacity of the soil: 500 tons of raw grain soil storage system

03

- Country: Indonesia

- Project name: 3-5T/H Animal feed pellet plant in Indonesia

- Main Raw materials: straw , alfalfa , husk , corn , soybean meal

- Total Power: 305KW

- Customer’s Feed Pellet Size: 6-12mm

- Plant size of project factory: 10m*5m*12m (L*W*H)

- The operate worker in this line: 4 person

Advantages of RICHI animal feed mill

The feed pellet plant has gained popularity among global feed enterprises and farmers due to its numerous advantages. It is characterized by high precision and efficiency, flexible adaptation, stable quality, and has achieved large-scale and standardized production compared to traditional methods. This has significantly improved the quality of feed and economic benefits.

As a symbol of advanced manufacturing process, stable output and long-term value, RICHI animal feed mill plant has become a widely trusted solution in the global biomass pellet industry with its strong structure, high-end components and intelligent design.

High-quality construction, stable and long-lasting operation

All key components of the pellet machine, from the ring die to the press roller, are made of high – strength stainless steel with excellent wear and fatigue resistance. At the same time the core components use world – renowned brands like SKF bearings and Siemens motors, ensuring stable operation and a very low failure rate.

The modular design simplifies post – maintenance, enhances component commonality and interchangeability, and greatly reduces long – term operation and maintenance costs of the equipment.

Intelligent and convenient operation, adapt to various scenarios

The RICHI animal feed pellet press has a compact structure and a small footprint, making it suitable for multiple production scenarios. It is also equipped with a fully automatic lubrication system, which significantly reduces the frequency of manual maintenance and extends the service life of equipment components.

The intelligent variable-frequency feeding system can automatically adjust the feeding speed according to the equipment load, ensuring stable and full-load operation of the equipment, effectively preventing blockages.

High cost performance, full service, global delivery

While maintaining quality, RICHI always adheres to high value-for-money principles, helping customers reduce investment costs. Whether it’s a single piece of equipment or an entire customized production line, we can provide customers with tailor-made solutions based on key factors such as raw material types, production capacity requirements, and market conditions.

We also offer comprehensive services including rapid delivery, remote guidance, and on-site commissioning.

RICHI’s animal feed mill plants for sale have been exported to 100+ countries and regions around the world. They have accumulated numerous successful cases in Africa, Asia, the Middle East, Europe, and the Americas, and are highly trusted by customers. Whether it’s building a new production line or expanding and upgrading, RICHI can provide you with reliable equipment and professional service support.

Frequently Asked Question

What is an animal feed mill plant?

It is a set of equipment specially used to process corn, wheat, soybean meal and additives and other crop raw materials into animal feed particles with balanced nutritional components and uniform appearance. The production process usually covers several key sections such as crushing, mixing, granulation, cooling and packaging.

The overall animal feed making machine price usually ranges from USD 10,000 to USD 2,800,000, depending on plant scale, output, and configuration. A well-designed production line can significantly reduce feed costs while ensuring consistent feed quality.

What kinds of animal feed can this production line produce?

Our animal feed production equipment can utilize a wide range of raw materials, including staple energy sources such as grains (corn, wheat, barley), high-quality protein sources like soybean meal, fish meal, and meat meal, energy supplements from oils (soybean oil, fish oil), coarse feed ingredients (straw, forage), and mineral additives to meet diverse processing requirements for various animal feeds.

What is the range of production of your animal feed mill plant for sale?

Our production line has a range of output from 1 tons per hour to 100 tons, which can meet the needs of small farmers to large commercial feed plants. If the customer needs it, we can also customize the production line as required

What raw materials can be used in this animal feed mill ?

The raw materials of this production line mainly include corn, wheat, rice bran, soybean meal, cottonseed meal, fish meal, alfalfa grass and various feed additives. Generally speaking, as long as the raw material moisture content and particle size meet the requirements, they can be used in our pellet machine for pellet production.

Can this animal feed mill plant customize feed formula for specific animals?

Yes, we have a team of experienced nutritionists and engineers who can provide you with scientific formula customization programs for different animal species and breeding objectives to improve feed utilization and animal health.

One-stop service

RICHI Machinery turnkey service covers many aspects, including solution design, equipment production, goods transportation, and after-sales service, and can provide you with comprehensive and perfect animal feed production line project services.

Design

A successful animal feed mill plant begins with a good design, and it needs to take into account various factors simultaneously: production capacity, raw material characteristics, available land, production process efficiency, and even future expansions that you haven’t thought of yet.

Our design process begins with in-depth communication. We can tailor the design based on your requirements, from your raw material resources to the factory space, and analyze in advance the potential production bottlenecks that may arise. We will create a detailed visual layout for you, simulating every step from raw material entry to finished product packaging in advance. This not only enables you to see the future factory before construction begins, but also avoids layout mistakes that are only discovered after construction and are costly to rectify.

Manufacture

All the core machinery is produced in our own factory and undergoes strict quality control procedures. Every detail is meticulously checked. Starting from the selection of high-grade steel and wear-resistant parts, to the adoption of advanced welding, processing and surface treatment techniques, we ensure that the equipment is both durable and efficient.

What we produce are not just functional machines, but machines that can operate continuously and stably over a long period of time. Whether it’s the ring die of the granulator, the gearbox, or the motor, we use core components from international brands such as Siemens, SKF, and ABB to ensure that your feed mill not only gets off to a strong start, but also maintains stability for a long time. All products in the production line meet international certifications like ISO, CE, SGS.

Test-run

Before shipment, we will conduct a comprehensive inspection of the equipment once again. Each machine will undergo full-load trial operation in the factory to test its operational stability, consistency of output, energy consumption level, and so on.

This step is by no means just a formality; rather, it is to ensure that those minor details that might later become major problems are identified and resolved in advance. This way, when the equipment arrives at the site, the installation process will be smoother and the debugging process will be more efficient. And your first batch of products can be released with peace of mind.

Logistics

Delivering large industrial equipment safely from our factory to your site is no easy task. We take full responsibility for every step, from custom packaging, container loading, to transportation arrangements, customs declaration documents, and final delivery.

The logistics team collaborates with reliable international transportation companies to ensure that your equipment arrives on time and safely, avoiding any unexpected incidents at the last minute.

Civil Construction

The quality of the animal feed mill plant depends on the infrastructure it is based on. Our engineering team will provide you with detailed construction drawings for the civil works, foundation requirements, utility connection plans, and ventilation system design specifications.

If you already have a local construction team, we will closely cooperate with them to ensure that the factory structure and equipment requirements are perfectly matched, avoiding rework and allowing the equipment to be installed on site as soon as it arrives.

Installation

The installation process is not just about placing the machines in the right position. The installation team of RICHI will ensure that each piece of equipment is precisely positioned, leveled, and connected according to the design plan. We are responsible for the electrical wiring, pneumatic systems, and all other necessary technical connections.

Once we complete the installation, your factory will not only look capable of operation, but will actually be able to commence production.

Commissioning

Once everything is in place, we fine-tune the system. Commissioning involves adjusting process parameters, synchronizing equipment speeds, and testing output quality to ensure that the equipment and systems operate smoothly in accordance with the design requirements.

We don’t leave until your production meets both our standards and yours.

Training

Your animal feed mill plant is only as good as the people running it. We provide on-site, hands-on training for your operators—covering daily operation, safety protocols, troubleshooting, and preventive maintenance.

By empowering your team with practical skills, we reduce the risk of downtime and make sure you get the best return on your investment.

After-Sales Service

The completion of equipment delivery does not mark the end of the project; instead, it signifies the beginning of a cooperative relationship. Our dedicated service team offers rapid technical support, whether it’s remote diagnosis, video guidance, or on-site services when necessary. We can solve your problems within the shortest time possible. Additionally, we always have an adequate inventory of original factory spare parts to ensure prompt delivery of accessories and minimize downtime.

Choosing us means you receive not just a set of equipment, but a long-term reliable partner. Even years later, you will still enjoy the same prompt and professional support as in the initial stage of the project.