Animal Feed Making Machine Price

Animal feed making machine price is one of the most concerned issues for investors when planning to build or upgrade a feed mill. It does not simply refer to a pellet mill, but represents the comprehensive cost of the entire set of feed processing and production equipment.

Animal feed making machine mainly includes crusher, mixer, granulator, cooler, vibrating screen and packaging scale. Equipment prices vary depending on production capacity, technology level, and degree of automation.

What is the animal feed making machine?

When considering the animal feed making machine price, you first need to understand what is animal feed making machine.

Animal feed making machine is a kind of equipment specially used for producing feed for poultry, livestock, ruminants and aquatic animals. It processes raw materials such as corn, soybean meal, bran, straw, and fish meal into uniform, nutritious pellets that are easy for animals to consume and digest.

In animal feed production, the main components include:

- Crusher: Grinds the raw materials into small particles.

- Mixer: Uniformly blends the various raw materials.

- Animal feed pellet mill: Presses the mixture into pellets of a specific diameter and shape.

- Cooler: Reduces the temperature and moisture content of the pellets for subsequent transportation and storage.

- Vibrating screen: Screens out broken or substandard pellets.

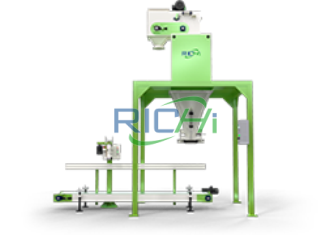

- Bagging scale: Automatically weighs and packages the finished feed.

The entire system typically begins with raw material grinding, followed by mixing, conditioning, pelletizing, cooling, screening, and packaging. Each link requires special equipment, and the combination of these equipment not only determines the quality of the feed, but also determines the animal feed making machine price.

Application Solutions for Various Needs

RICHI’s feed production systems are able to adapt to a variety of raw materials and produce high-quality pelleted feed for poultry, livestock, ruminants, and aquaculture. This flexibility ensures that regardless of the size of the customer’s farm or the target species, they can find the ideal equipment configuration within their budget and achieve efficient production.

Livestock Feed Production Line

Aquatic Feed Plant

Ruminant Feed Production Line

Video Showcase of animal feed making machine

Before investing, since animal feed making machine prices vary depending on output, configuration, and degree of automation, watching actual production videos can help you better understand the value of the equipment. In this video, you’ll see the complete feed production process—from raw material crushing, mixing, and pelleting to cooling and packaging—and the efficiency and quality of RICHI equipment in action.

Different Technical Parameter Of RICHI Animal Feed Making Machine For Sale

RICHI animal feed making machine for sale provides feed manufacturers with efficient and high-quality pellet feed solutions. Users can process raw materials into uniform, nutritious pellet feed, ensuring stable feed quality and improving feed utilization. Animal feed making machine price varies depending on the configuration of the equipment.

Vibrating screen

Price: 2,000-10,000 USD

structural characteristics Of Animal Feed Making Machine

When discussing animal feed making machine price, it’s important to understand its structural features, as the equipment’s design and build quality directly impact its operating efficiency, versatility, and long-term investment value. The RICHI animal feed making machine utilizes a modular design, intelligent control system, and a wide range of adaptability to meet diverse feed production needs worldwide.

Different Animal Feed Making Machine Price In Global Projects

Animal feed making machine prices are not fixed and can vary significantly between projects in different countries and regions. Their price is influenced by numerous factors, including production capacity, formulation type, local raw material availability, power configuration, and degree of automation.

RICHI Machinery has over 30 years of experience in equipment manufacturing, with projects spanning over 140 countries and regions worldwide. Whether for medium- to large-scale farms or commercial feed mills of various sizes, we can provide customized pellet equipment products and pellet plant solution tailored to your specific needs, achieving the best cost-performance ratio, ensuring stable operation, and delivering a high return on investment.

- Project Name: 5T/H fish feed manufacturing plant

- Project country: Uzbekistan

- Project output: 5T/H

- Raw materials: Corn, soybean meal, rice bran, wheat flour, fish meal, and bone meal

- Fish feed machine price: About 85,000 USD

- Project Name: 1-2T/H chicken feed production line

- Project country: Angola

- Project output: 1-2T/H

- Raw materials: Maize, soybean meal, wheat bran, fish meal, bone meal, salt, and vitamin-mineral premixes

- Chicken feed making machine price: About 30,000 USD

- Project Name: 3.5T/H cattle feed production line

- Project country: Poland

- Project output: 3.5T/H

- Raw materials: Corn, wheat bran, soybean meal, rapeseed meal, alfalfa, salt, vitamins, and mineral premix

- Poultry feed making machine price: About 62,000 USD

- Project Name: 10T/H animal feed mill plant

- Project country: Afghanistan

- Project output: 10T/H

- Raw materials: Corn, wheat bran, barley, soybean meal, alfalfa, cottonseed meal, and molasses

- Animal feed making machine price: About 175,000 USD

Why Choose Our Animal Feed Making Machine

We understand that when customers consider the animal feed making machine price, they aren’t just looking for cheap equipment; they want every penny they spend. RICHI Machinery’s equipment utilizes high-quality materials, advanced processing, and rigorous quality control to ensure high output, low maintenance costs, and an exceptionally long service life. This means your investment will yield maximum performance and efficiency for years to come.

At the same time, we strive to maintain reasonable prices by improving production efficiency and partnering directly with high-quality global suppliers. This is why customers in over 140 countries trust RICHI.

High Cost Performance with Reliable Quality

RICHI always ensures every machine truly delivers value for money. We use high-strength steel, advanced machining centers, and precision assembly to guarantee stable performance and long service life.

Each equipment undergoes strict testing before delivery, ensuring smooth operation and fewer breakdowns. For customers, this means reduced maintenance costs, higher productivity, and faster return on investment. When you invest in RICHI, you are not only buying equipment, but also investing in many years of reliable production and consistent quality.

Certified Quality Meeting International Standards

All RICHI animal feed making machines are built under strict international standards and carry global certifications such as CE, ISO, and SGS. These certificates are not just labels — they prove our commitment to safety, energy efficiency, and environmental responsibility.

From material sourcing to final inspection, every step follows rigorous quality control to ensure compliance with the import requirements of countries across Asia, Europe, Africa, and the Americas. Choosing RICHI means choosing equipment that has passed the test of global markets.

Trusted by Customers in 140+ Countries

With over 30 years of manufacturing experience and projects in more than 140 countries, RICHI feed production systems have shown excellent adaptability to different climates, raw materials, and customer demands.

Whether in poultry, livestock, ruminant, or aquafeed production, our machines deliver consistent performance and reliable results. Customers continue to choose RICHI not only for our competitive prices but also for our technical support, after-sales service, and commitment to helping their feed businesses grow steadily.

In addition to providing high-quality equipment, RICHI Machinery turnkey service is customized according to customer needs to ensure that users can smoothly start feed production and achieve long-term profitability.

FAQ

When it comes to animal feed making machine prices, customers often have many questions, such as what factors affect the price, how to choose the right configuration, and so on. To help you make an informed choice, we have compiled some frequently asked questions about RICHI feed making equipment.

What is the animal feed making machine price?

+

An animal feed making machine doesn’t simply refer to a pellet machine; it represents the comprehensive cost of an entire feed processing and production facility. Prices vary significantly depending on the equipment type, production capacity, level of automation, and whether auxiliary equipment such as a grinder, mixer, pelletizer, cooler, and packaging system is included.

For example, a low-capacity production line for poultry or livestock may only require a pelletizer, priced between USD 7,000 and 85,000. A medium- to large-scale feed mill, however, may require a full suite of auxiliary equipment, potentially costing more. RICHI offers customized solutions tailored to your production needs and budget, ensuring efficient and cost-effective equipment.

How do I choose the most suitable animal feed making machine within my budget?

+

Choosing the right animal feed making machine requires balancing production needs and budget. Here are a few key considerations:

- Determine production capacity: First, determine the amount of feed you need to produce daily and align the machine’s capacity with your production goals.

- Consider the power source type: Electric machines are energy-efficient and suitable for areas with stable power supplies, while diesel or PTO machines offer greater flexibility and are suitable for remote locations.

- Evaluate additional features: Features like automatic lubrication systems, cooling systems, and PLC controls can improve efficiency and reduce labor costs, but may increase the initial investment.

- Select a manufacturer: Partner with a reliable manufacturer who can provide tailored solutions tailored to your production needs and budget, helping you select the most cost-effective equipment.

By carefully considering these factors, you can choose a cattle feed pellet machine that meets your production needs while staying within your budget.

Can an animal feed making machine also produce feed for different animals?

+

Well, not entirely. While RICHI’s animal feed making machines are indeed flexible and can handle a wide range of raw materials, not just any machine can produce all types of feed for different animals. For example, feed for ruminants (like cattle) or aquatic species (fish and shrimp) sometimes requires additional conditioners or extruders to ensure pellet texture, nutritional content, and even buoyancy meet the required standards.

However, with the right auxiliary equipment and some simple system adjustments, a single animal feed pellet production line can still produce a variety of feeds. The key is advance planning: first determine the type of animal you’re feeding, the pellet specifications and types required, and then configure the equipment accordingly. This not only saves time, cost, and space, but also ensures the production of high-quality, diverse feeds.

If I want a machine with 3T/H capacity, how much does it cost?

+

Animal feed making machine prices generally range from $60,000 to $200,000, depending on the raw material type, configuration, and level of automation. If raw material processing is required or if high-quality feed pellets are to be produced, the configuration will be higher and the price will be higher. If the raw material meets pelleting requirements or additional configuration is not required, the price will be lower.

RICHI always strives to provide excellent value for every machine, ensuring high-quality materials and stable performance while maintaining reasonable and competitive prices.