complete wood pellet plant

A complete wood pellet plant is an integrated system designed to convert forestry waste, agricultural residues, and biomass materials into compacted cylindrical fuel pellets. These pellets are widely used in heating systems, power plants, and industrial boilers due to their clean combustion, high energy efficiency, and environmental benefits.

overview of Complete Wood Pellet Plant

— Richi Machinery —

brief introduction

The complete wood pellet plant is a complete equipment system that processes wood waste materials such as logs, sawdust, and wood scraps into high-density pellets (2-12mm in diameter) through core stages including crushing, drying, granulation, cooling, and screening.

By incorporating agricultural residues like crop stalks, rice husks, and palm shells into the raw materials, this system diversifies feedstock sources, thereby enhancing both production adaptability and material utilization efficiency.

The RICHI wood pellet plant is equipped with comprehensive and professional process equipment, covering the entire production process from raw material pretreatment to pellet packaging. Featuring a wide range of models and significant output capacity spans, it can produce between 0.3 tons/hour and 40 tons/hour.

This system effectively meets diverse production needs across individual farms, medium-sized processing plants, and large-scale biomass fuel enterprises. Significant differences exist in equipment configuration, investment costs, and application scenarios depending on varying production capacities.

The wood pellet plant is an ideal solution for converting biomass into clean renewable energy. Whether you are small and medium-scale production or building a large factory, RICHI can provide one-stop services from design, equipment, installation to after-sales training. Choose RICHI MACHINERY to create a green future together.

Usage

It is widely used as biomass fuel, cat litter, and so on.

Raw materials

wood waste materials such as logs, sawdust, wood scraps and so on.

Production capacity

0.3-40 T/H

Pellet Size

4-12 mm

Key Features Of Wood Pellet Plant

Complete wood pellet plant is an efficient systematic solution integrating raw material treatment, granulation and forming, cooling and packaging. In order to meet the output and application needs of different customers, this system has the following core characteristics:

Complete process flow and high degree of automation

The wood pellet plant is designed as a complete system that covers all steps: raw material preprocessing (chipping & crushing), drying, pelletizing, cooling, screening, and packing.

Integrated with PLC or SCADA automation systems, it allows centralized control, real-time monitoring, and fault alarms, significantly reducing manual labor.

Wide range of applicable raw materials, adjustable pellet size

It supports a wide range of biomass raw materials including wood chips, sawdust, bamboo, straw, palm fiber, coconut shell, and agricultural residues.

The pellet diameter can be adjusted from 2mm to 10mm, suitable for various applications like home heating, BBQ fuel, industrial boiler fuel, and biomass power generation.

Flexible capacity allocation and modular structure design

Production capacities range from 0.3T/H to 40T/H, making the line suitable for startups, mid-scale factories, and large industrial plants.

Thanks to its modular design, each part can be upgraded, replaced, or expanded independently without affecting the overall system.

Energy saving and environmental protection design, low operating cost

Equipped with energy-efficient motors, dust removal systems, and heat recovery units, the complete wood pellet plant ensures low power consumption and reduced emissions, fully compliant with global environmental standards.

Working process of complete wood pellet plant

The production process of the wood pellet production is: pretreatment → crushing → drying → granulation → cooling and screening → packaging

1. Raw Material Collection & Pre-treatment

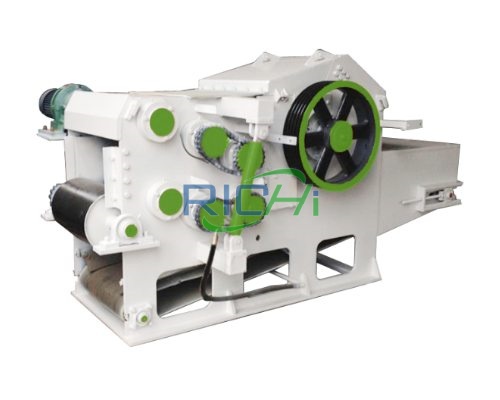

This production line is designed to process various biomass materials including logs, branches, and wood processing residues (such as shavings, sawdust, and trimmings). For larger, harder logs or blocks, the system first uses a drum chipper to perform preliminary crushing, cutting them into 2-3cm wood chips. Operators can adjust blade rotation speed and feed rate according to material type and hardness, ensuring optimal chip quality while maintaining stable equipment operation.

2. Crushing Section

The wood chips after cutting and the uncut wood raw materials, such as branches, wood chips, waste scraps, will be sent to the wood chip hammer mill for further processing, so that the wood chips can be crushed into small wood chips of 3-5mm to meet the requirements of granulation.

3. Drying Section

In order to ensure the molding rate and quality of wood pellets in the complete wood pellet plant, the moisture content of raw materials must be controlled between 12%-18%. A rotary drum dryer is used to fully contact the raw materials with hot air, evaporating the moisture. By controlling temperature and drum rotation speed, rapid, uniform, and stable drying can be achieved.

4. Pelletizing Section

After drying, the wood chips enter the wood granulator. The material is sent into the ring molding machine through the feed opening and pressed into the mold hole by the pressure of the roller. Customers can choose different sizes of molds according to different needs to produce high density cylindrical pellets.

5. Cooling & Screening Section

The newly formed granules reach temperatures of 70-90℃ with high humidity, making them prone to deformation or mold growth – requiring immediate cooling. By employing a counterflow cooler that allows cold air to flow in reverse against the hot granules, rapid temperature reduction is achieved. The system also incorporates a vibrating screen to separate qualified pellets from debris and powder. Non-conforming pellets are recycled back to the granulation process for reuse, enhancing raw material utilization efficiency and reducing waste.

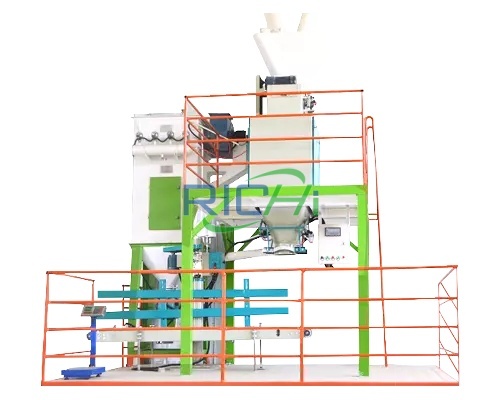

6. Packing Section

The cooled pellets are weighed, bagged and sewn by an automatic packaging system. Packaging specifications can be set according to customer requirements. The final product can be used in heating, industrial fuel, boiler combustion and other fields.

Supplementary note: the whole complete wood pellet plant is equipped with a feeding bag, which is convenient for different stages of feeding, and adopts efficient conveying methods such as air delivery and conveyor belt to greatly improve the efficiency of section connection.

Key equipment for starting a complete wood pellet plant

— RICHI Machinery —

To ensure continuous and high-efficiency production, the plant also requires a range of pellet equipment products such as wood chip crushers, rotary drum dryers, pellet coolers, and automatic packaging systems.

RICHI MACHINERY

core equipment of complete wood pellet plant

After going through the wood pellet plant, the next key focus is the pellet equipment products—the heart of any wood pellet plant. This machine is responsible for compressing raw materials into uniform, high-density pellets, and directly affects the plant’s output, pellet quality, and energy efficiency. In the following section, we will explore the structure, working principle, and technical parameters of the wood pellet mill in detail.

- Feeder

- Variable-frequency feeding motor

- Gearbox

- Siemens motor

- Granulation chamber

- Forced feeder

- Manual feeding port

- SKF bearing

- Lifting device

RICHI offers a variety of specifications and models of wood pellet machines to meet the needs of different production volumes and application scenarios.

| Model | MZLH320 | MZLH350 | MZLH420 | MZLH520 | MZLH678 | MZLH768 |

| Output (t/h) | 0.2-0.3 | 0.3-0.5 | 1.5-2.0 | 2.0-2.5 | 2.5-3.0 | 3.0-4.0 |

| Main motor power (kw) | 22 | 37 | 90 | 132 | 185 | 250 |

| Main motor series | 6/8p | 6/8p | 6/8p | 6/8p | 6/8p | 6/8p |

| Ring die diameter (mm) | 320 | 350 | 420 | 520 | 673 | 762 |

| Finished pellet diameter (mm) | 4-12 | 4-12 | 4-12 | 4-12 | 4-12 | 4-12 |

(Note: RICHI Machinery’s products are always updated and improved. If you have any questions, please feel free to contact us at any time.)

global cases Of wood pellet plant

120+ /countries and regions

As the world’s first-class manufacturer and supplier of wood pellet equipment, RICHI MACHINERY Co., LTD. has been exported to 127 countries and regions, and then has won unanimous praise from customers.

1,000+ /PROJECTS

We have done more than 1000 wood pellet plant solutions around the world and have accumulated rich experience in the construction of complete wood pellet plants. And these projects are located in Europe, Africa, Asia, North America, South America, and Oceania.

1-2T/H

- Project country :Indonesia

- Project name: 1-2T/H Wood pellet production line in Indonesia

- Project output:1T/H

- Raw materials: Wood chips

- Finished product & size: 8mm

- Main equipment for the project: Drying, Wood pellet press machine, Cooling, Screening, Automatic packaging

- Project background: The forest resource processing industry in Indonesia is highly active, generating a large amount of wood chips and waste materials. This not only leads to waste of resources but also poses pressure on environmental protection treatment. To achieve resource recycling, respond to environmental protection policies, and fill the market gap, this client plans to build a 1 – 2T/H wood chip pellet production line. Relying on equipment such as dryer and wood chip granulator, it converts wood waste into standardized pellet products, promoting the development of green economy and waste resource utilization.

2-3T/H

- Project country :Canada

- Project name: 2-3T Full automatic biomass wood pellet line in Canada

- Project output:2-3T/H

- Raw materials:50% Moisture wood chips , 50% moisture sawdust

- Finished product & size: 6-12mm

- Main equipment for the project :Wood crusher, Shifter, Dryer, Storage Bin, Wood pellet machine, Grass pellet machine, Cooler, Shifter , Auto-packing

- Project background:In the North American energy market, the demand for biomass pellets as a clean-burning energy source is constantly increasing. Canada has abundant forest resources, but the wood processing sector accumulates a large amount of mixed waste. This client has invested in a 2 – 3T/H fully automatic production line to convert forestry waste into high-value-added pellet fuel. This not only solves the problem of resource waste but also meets the requirements for environmental protection.

3-5T/H

- Project country :Thailand

- Project name: 3-5T/H Complete wood pellet plant in Thailand

- Project output:3-5T/H

- Raw materials: Wood chips

- Finished product & size: 8-10mm

- Main equipment for the project: Drying, Wood chip pellet machine, Cooling, Screening, Automatic packaging

- Project background:The forestry processing industry in Thailand is highly developed, generating a large amount of wood waste during the processing stage each year. The traditional landfill disposal method not only wastes resources but also pollutes the environment. To achieve resource recycling and fill the market gap, this client invested in a 3-5t/h wood chip pellet plant, integrating drying, pelletizing, packaging and other equipment, converting wood chips into standardized pellet products, and promoting the resource utilization of forestry by-products.

10T/H

- Project country :America

- Project name: 10T/H Wood pellet manufacturing plant in America

- Project output:10T/H

- Raw materials: Wood chips

- Finished product & size: 8mm

- Main equipment for the project: Wood Crusher, Shifter, Drying, Wood granulator machine, Cooling, Screening, Automatic packaging

- Project background:The forestry and wood processing industry in the United States is large-scale, generating a huge amount of wood waste every year. The processing cost is high and it also causes environmental burdens. This client plans to build a 10T/H wood chip plant. Relying on equipment such as wood crushers and screens, the wood waste will be converted into standardized pellet products, helping to build a circular economy and a green energy system, and filling the market demand gap for high-quality biomass fuel.

RICHI MACHINERY

Advantages Of RICHI wood pellet plant

After learning about the production process and core equipment of the complete wood pellet plant, you might be curious about why choosing our solution would be more reliable and efficient. Next, we will elaborate on our unique advantages from aspects such as technical strength, project experience, and service guarantee. This will help you make a more informed decision when investing in a wood pellet production line.

One-stop turnkey solution with personalized design support

RICHI offers you a turnkey project service for your complete wood pellet plant, starting from scratch – from pre-construction consultation, plant layout design, equipment manufacturing, logistics transportation, to on-site installation, trial operation and commissioning, as well as employee training.

We will oversee every aspect of the project throughout the process to ensure its successful implementation.

Each production line is custom-made according to the actual needs of the customers. Comprehensive consideration is given to the types of raw materials (such as sawdust, wood chips, forestry waste, agricultural straw, etc.), factory conditions, target output, energy type, automation level, and the product quality standards of the local market, to formulate the most suitable plan.

The core components are selected from international brands, and the system has strong stability

All key components have been carefully selected and are sourced from globally renowned brands, ensuring the long-term stable operation of the equipment and extending its service life. We utilize Siemens motors to provide stable power, SKF bearings to guarantee smooth and low-resistance mechanical operation, and Schneider Electric electrical components to achieve precise and safe control.

Such high-end configuration not only effectively reduces downtime and maintenance costs, but also ensures that the entire production line remains efficient, durable, and stable even after years of high-load production.

Global service system, support remote and on-site technical services

RICHI has successfully implemented numerous wood pellet production projects in over 120 countries worldwide, covering various scales ranging from small production lines to large fully automated factories.

Over the years, we have established an efficient and responsive after-sales service network, ensuring that professional engineers can provide remote guidance and on-site technical support at any time. This not only enables customers to obtain advanced equipment and mature process solutions, but also ensures the long-term stable and efficient operation of the production lines.

Complete set of supporting equipment, system integration configuration

RICHI not only provides you with a complete wood pellet plant solution, but also offers individual equipment. Besides the core pelletizing machine, we also supply all necessary auxiliary equipment such as a grinder, a screw conveyor, a cooling machine, and an automatic packaging machine.

By uniformly supplying the complete set of equipment, we ensure stable system operation and maximum energy efficiency. This also significantly simplifies the installation and commissioning process. Your production line will operate as a complete unit, producing high-quality pellets stably.

RICHI MACHINERY

How to choose the right wood pellet plant?

Selecting the right complete wood pellet plant for sale is crucial for ensuring efficient, cost-effective, and long-term pellet production. Here are the key steps to guide your decision-making process.

01

Confirm Raw Material Type and Moisture Content

Large materials in volume may not be able to enter the granulator directly, while high moisture content will directly affect the granulation efficiency and the configuration of drying process.

Therefore, it is necessary to determine whether pre-treatment equipment such as drying or pulverizing is needed.

02

Determine the required Capacity and Match Investment Budget

When choosing a complete wood pellet plant, both target capacity and investment budget are important factors to consider at the same time.

The number of equipment, model configuration and degree of automation required by different budgets and capacity requirements will vary greatly.

03

Verify the local electricity usage standards

Voltage and frequency standards vary by region. Electrical parameters can be affective to motor models, control systems, and inverter configurations.

Therefore, it is essential to verify local electrical standards in advance to avoid equipment malfunctions caused by power mismatches.

Every project has its own characteristics. Whether you are a first-time investor or an experienced pellet manufacturer, RICHI technical team can customize a complete set of solutions according to your raw material characteristics, output requirements, plant layout and automation requirements, so as to help you avoid blind investment and build a truly practical and efficient pellet plant.

If you need pellet plant solution or a personalized quotation, feel free to contact us — RICHI is ready to support you with professional expertise and turnkey pellet production solutions!

Frequently Asked Questions

Customized solutions can help different customers meet their unique business needs, improve efficiency, and reduce costs.

All of RICHI’s wood pellet plant are custom designed.

What sizes of pellets can be produced?

The RICHI complete wood pellet plant supports production of various specifications of wood pellets, with the standard model typically producing 6-12mm pellets. For home heating applications, 6-8mm pellets are commonly used, while industrial boilers and power plants prefer pellets exceeding 10mm in diameter. Featuring a modular ring die design, this equipment allows users to replace dies with different hole sizes as needed, enabling a single machine to accommodate multiple diameter specifications.

What is the moisture requirement for raw materials?

It is recommended to maintain moisture content between 12%-18%. The raw material’s water percentage directly impacts pellet formation quality. Excessive moisture can cause pellets to become loose, weaken in strength, or even fail to form during granulation. Therefore, it’s crucial to verify whether drying treatment is required. When necessary, the RICHI drum dryer should be used as a complementary solution to ensure stable compaction and high pellet formation efficiency.

What types of raw materials can you deal with?

Our machine is compatible with various biomass materials including sawdust, wood chips, bark, bamboo chips, rice husks, palm shells, and corn stalks. As long as the raw materials meet pellet production requirements (3-5mm powder size, moisture content 12%-18%), they can be processed using our equipment. Additionally, we provide customized crushing and drying systems based on material moisture levels and pellet sizes to achieve optimal pellet formation.

Can I just buy a single machine?

Beyond customizing complete wood pellet plants, we also provide tailored solutions based on specific needs. For instance, if a client requires only raw material crushing or moisture reduction, they can purchase individual equipment like crushers, slicers, or dryers. Whether you choose a single unit or an integrated system, we arrange logistics and send technicians for on-site installation and commissioning at no extra cost.

What’s the typical output capacity of the complete wood pellet plant ?

It has a range of output from 0.3 tons to 40 tons per hour. RICHI provides a variety of modular solutions for small household to large industrial projects. Depending on the plant requirements and budget, RICHI will recommend the most suitable pelletizing machine model and supporting solutions for you.